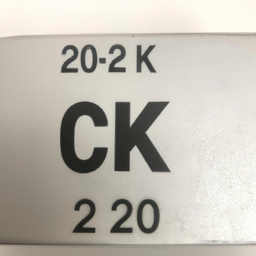

CK20 steel is a medium carbon, low alloy steel grade that is popularly used for engineering and construction purposes. It has a good mechanical property and excellent machinability, making it suitable for various fabrication processes. It is also corrosion resistant and wear-resistant, making it suitable for various applications that require durability and strength.

Chemical Properties of CK20 Steel

CK20 steel is composed of the following chemical elements: iron, carbon, manganese, phosphorus, sulfur, silicon, chromium, and nickel. Iron is the primary element, making up about 98% of the alloy. Carbon is the second most important element, making up about 0.5%. Manganese, phosphorus, and sulfur make up about 0.3%, 0.05%, and 0.05% respectively. Silicon and chromium account for up to 0.3% and nickel up to 0.25%. The remaining elements make up less than 0.1%.

Composition of CK20 Steel

CK20 steel has a composition that is composed of the following elements in percentages: iron (98%), carbon (0.5%), manganese (0.3%), phosphorus (0.05%), sulfur (0.05%), silicon (0.3%), chromium (0.3%), and nickel (0.25%).

Mechanical Properties of CK20 Steel

CK20 steel has an excellent tensile strength of 600-800 MPa, which is suitable for various engineering applications. It also has good ductility and can be easily formed into various shapes. The yield strength of CK20 is 510 MPa, and its impact strength is 12.5 J/cm2. Additionally, it has a good hardness range of 170 – 250 HBW.

Uses of CK20 Steel

CK20 steel is commonly used for various engineering and construction purposes. It is used for making bolts, nuts, screw-machine parts, shafts, and various other components. It is also used for making automotive components, as well as for making cutting tools. Furthermore, CK20 steel is used in various industrial applications, including for making gears, valves, and bearings.

Conclusion

CK20 steel is a medium carbon, low alloy steel grade that is popularly used for engineering and construction purposes. It has a good mechanical property and excellent machinability, making it suitable for various fabrication processes. It has an excellent tensile strength of 600-800 MPa, good ductility, and a good hardness range of 170 – 250 HBW. CK20 steel is commonly used for making bolts, nuts, screw-machine parts, shafts, automotive components, cutting tools, and various other components.