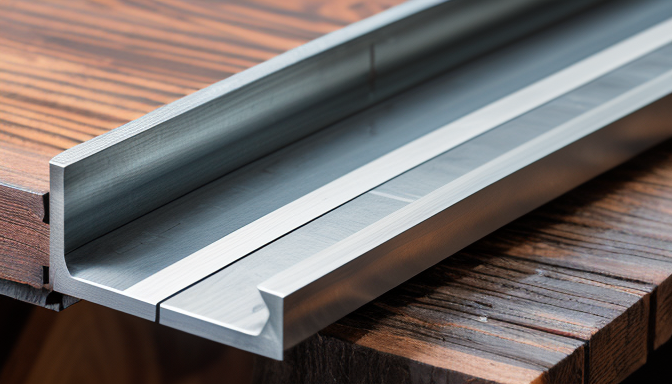

When it comes to construction and engineering, thick-walled steel hollow section profiles play a significant role. These profiles are not just ordinary steel shapes; they are the backbone of many structures. Think about it: every time you see a skyscraper or a bridge, there’s a good chance that thick-walled steel hollow sections are part of the story. They provide strength and stability, making them essential in various applications.

These profiles come in different shapes and sizes, but they all share a common feature: a thick wall. This thickness is what gives them their strength. Imagine trying to bend a thick metal rod versus a thin one. The thicker rod will resist bending much better, right? That’s exactly how these hollow sections work. They are designed to handle heavy loads and resist external forces, ensuring that structures remain safe and durable.

Now, you might wonder, what makes these profiles so popular? Well, it’s not just about strength. They are also versatile. You can find them in various applications, from residential buildings to industrial facilities. They can be used for:

- Structural support

- Frameworks for buildings

- Bridges and overpasses

- Heavy machinery frames

Moreover, their hollow design allows for easy handling and installation. It’s like carrying a suitcase with wheels instead of a heavy backpack. The hollow sections are lighter than solid steel, making transportation and assembly easier without compromising on strength.

But what about the cost? That’s a vital aspect for any project. The price of thick-walled steel hollow sections can vary significantly based on several factors. These include the quality of the material, current market demand, and the supplier’s pricing strategy. If you’re planning a project, it’s crucial to get accurate quotes and consider these factors to stay within budget.

In summary, thick-walled steel hollow section profiles are a key component in modern construction. Their strength, versatility, and ease of use make them a favorite among engineers and builders alike. Whether you’re working on a small renovation or a massive infrastructure project, understanding these profiles can help you make informed decisions. So, the next time you see a sturdy structure, remember the thick-walled steel hollow sections that help hold it all together!

Thick-Walled Steel Hollow Section Profile Price

Understanding the pricing of thick-walled steel hollow sections is crucial for budgeting your projects. Imagine you’re planning a construction venture. You need to know how much you’re spending, right? Various factors influence these costs, making it essential to grasp the market dynamics. First, consider the material quality. Higher quality steel often comes with a heftier price tag. But why? Well, it’s all about durability and performance. Cheaper materials might save you money upfront, but they can cost you more in the long run due to repairs and replacements.

Next up, we have market demand. When demand spikes, so do prices. It’s simple economics. If everyone wants thick-walled steel hollow sections, suppliers know they can charge more. This fluctuation can make budgeting tricky. It’s like trying to catch a wave; you need to time it just right to ride it smoothly.

Another piece of the puzzle is supplier pricing strategies. Different suppliers will have various pricing models. Some might offer bulk discounts, while others stick to fixed pricing. It’s wise to shop around. Compare prices from multiple suppliers to find the best deal. You wouldn’t buy the first car you see, would you? The same logic applies here.

Here’s a quick overview of some common factors that affect pricing:

- Material Quality: Higher quality equals higher costs.

- Market Demand: Prices rise with increased demand.

- Supplier Strategies: Different suppliers, different prices.

In conclusion, knowing these factors can help you make informed decisions. It’s not just about the price tag; it’s about understanding what you’re paying for. So, as you dive into your project, keep these insights in mind. They’ll help you navigate the world of thick-walled steel hollow section profiles with confidence.

Thick-Walled Steel Hollow Section Profile Weight

The weight of thick-walled steel hollow sections plays a significant role in both construction logistics and structural design. When you think about it, weight isn’t just a number. It’s a crucial factor that influences everything from transportation costs to the overall integrity of a structure. Imagine trying to lift a heavy object; if it’s too heavy, you might struggle, right? Similarly, in construction, the weight of steel profiles can impact how they are handled and installed.

Several factors contribute to the weight of these hollow sections, including their dimensions and the material used. Generally, thicker walls mean more weight, but it’s not always that simple. The shape of the profile also matters. For example, a square hollow section might weigh differently than a rectangular one, even if they have the same wall thickness. To give you an idea, here’s a quick look at how different dimensions can affect weight:

| Profile Size (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|

| 100 x 100 | 5 | 12.5 |

| 150 x 150 | 6 | 18.5 |

| 200 x 200 | 8 | 28.5 |

As you can see from the table, as the size and wall thickness increase, so does the weight. This increase can lead to higher transportation costs. For instance, transporting a larger, heavier profile requires more robust vehicles and may even necessitate special permits. Have you ever tried moving a large piece of furniture? It often requires more effort and planning than smaller items. The same principle applies here.

Moreover, the weight of these profiles is not just a logistical concern. It also affects the design of the structures they are used in. Engineers must account for the weight when calculating load-bearing capacities. If they underestimate this, it can lead to serious issues down the line. Think of it like building a bridge. If the materials are too light, it might not hold up; too heavy, and it could be over-engineered, wasting resources.

In summary, understanding the weight of thick-walled steel hollow sections is essential. It influences not only the cost and logistics of construction but also the safety and durability of the final structure. So, whether you’re a contractor, an engineer, or just someone interested in construction, keeping an eye on weight is a smart move!

Thick-Walled Steel Hollow Section Profile Properties

When it comes to thick-walled steel hollow sections, understanding their properties is key. These profiles are not just about looks; they pack a punch in terms of performance. Think of them as the sturdy backbone of many construction projects. So, what makes them so special?

First off, let’s talk about tensile strength. This is the measure of how much pulling force a material can withstand before it breaks. Thick-walled steel hollow sections boast high tensile strength, making them ideal for heavy-duty applications. Imagine trying to pull apart a thick rubber band versus a thin one. The thicker one holds up better, right? That’s the same principle here!

Next, we have durability. These steel profiles are designed to last. They resist wear and tear, which means they can handle the elements—rain, snow, or even extreme heat. This durability is crucial in construction, where materials face constant stress. Think of it as a reliable friend who always shows up when you need them!

Another vital property is resistance to environmental factors. Thick-walled steel hollow sections can withstand corrosion and rust, especially when treated with protective coatings. This means they won’t easily deteriorate over time, which is a huge plus in outdoor applications. Imagine building a bridge or a skyscraper; you want materials that will stand the test of time, right?

Now, let’s break down some of these properties in a simple table:

| Property | Description |

|---|---|

| Tensile Strength | Ability to withstand pulling forces without breaking. |

| Durability | Resistance to wear and tear, ensuring long-lasting performance. |

| Environmental Resistance | Protection against corrosion and rust for outdoor applications. |

In summary, the properties of thick-walled steel hollow sections make them a go-to choice for many engineers and builders. They are strong, durable, and can withstand various environmental challenges. If you’re involved in construction or engineering, knowing these properties can help you make informed decisions. After all, no one wants to cut corners when it comes to safety and reliability!

Thick-Walled Steel Hollow Section Profile Sizes

This article explores the various aspects of thick-walled steel hollow section profiles, including their pricing, weight, properties, sizes, and practical applications in construction and engineering.

When it comes to thick-walled steel hollow sections, size truly matters. The dimensions of these profiles can significantly influence their performance in various applications. So, what sizes are available? Well, the options are quite diverse, catering to different engineering needs. Typically, these profiles come in a variety of shapes, including square, rectangular, and circular. Each shape has its own set of advantages, depending on the intended use.

Choosing the right size isn’t just about aesthetics; it’s crucial for structural integrity. For instance, using a larger profile might seem appealing for strength, but it can also add unnecessary weight and cost. On the flip side, going too small can compromise stability. It’s a balancing act, much like finding the right pair of shoes; too tight, and you’re uncomfortable; too loose, and you’re prone to slips.

To make it easier, here’s a quick overview of some common sizes:

| Shape | Typical Sizes (mm) | Applications |

|---|---|---|

| Square | 50×50 to 300×300 | Frames, columns, and beams |

| Rectangular | 100×50 to 400×200 | Bracing, supports, and structures |

| Circular | 60 to 300 | Pipes, handrails, and posts |

When selecting a size, consider factors like load-bearing capacity, the environment it will be used in, and the overall design of the project. For example, a construction site in a windy area may require thicker walls and larger profiles to ensure stability. On the other hand, a smaller profile could be suitable for indoor applications where space is limited.

In summary, understanding the available sizes of thick-walled steel hollow sections can significantly impact your construction projects. It’s not just about picking a number; it’s about ensuring safety, efficiency, and cost-effectiveness. So, take your time, do your research, and choose wisely!

Frequently Asked Questions

- What are thick-walled steel hollow sections used for?

Thick-walled steel hollow sections are widely used in construction and engineering projects. They are ideal for structural applications where strength and durability are crucial, such as in building frameworks, bridges, and heavy machinery supports.

- How is the price of thick-walled steel hollow sections determined?

The pricing of these sections can vary based on several factors. Key influences include the quality of the steel, current market demand, and the pricing strategies of suppliers. It’s essential to compare quotes from different suppliers to get the best deal.

- What factors affect the weight of thick-walled steel hollow sections?

The weight is primarily influenced by the dimensions and thickness of the steel used. Larger and thicker sections will naturally weigh more, impacting transportation costs and structural considerations.

- What are the key properties of thick-walled steel hollow sections?

These sections are known for their impressive tensile strength, durability, and resistance to various environmental factors. This makes them suitable for demanding applications where reliability is a must.

- How do I choose the right size of thick-walled steel hollow section?

Selecting the appropriate size depends on your specific engineering needs. Consider factors such as load requirements, space constraints, and the intended application to ensure optimal performance.