The is a fundamental procedure in the fields of metallurgy and engineering. It measures the maximum stress that steel can withstand before it begins to deform permanently. Understanding yield strength is crucial because it helps engineers and builders choose the right materials for their projects. Imagine constructing a skyscraper. Would you want to use steel that can’t handle the weight? Of course not! Yield strength tells us how much load a steel beam can take before it bends or breaks.

In simple terms, yield strength is like the breaking point of a rubber band. Stretch it just enough, and it will return to its original shape. But pull too hard, and it snaps. Similarly, steel has its limits, and knowing those limits is key to ensuring safety and durability in construction.

There are different methods to test yield strength, such as the tensile test, which involves pulling a steel sample until it breaks. This method gives us a clear picture of how strong the steel is. Another method is the compression test, which pushes the steel to see how it holds up under pressure. Each method has its own perks and challenges, but they all aim to provide accurate and reliable results.

Now, you might wonder why this testing is so important. The answer is simple: safety. If a structure fails due to weak materials, the consequences can be disastrous. Think about bridges, buildings, and even cars. All rely on strong, reliable steel. In fact, according to industry standards, every piece of steel used in construction should undergo yield strength testing to ensure it meets safety regulations.

Moreover, yield strength varies with different types of steel. For example, high-strength steel is used in demanding applications, while mild steel is suitable for less critical uses. Knowing the properties of the steel you’re working with helps in making informed decisions. It’s like choosing the right tool for a job. You wouldn’t use a hammer to tighten a screw, right?

In conclusion, the steel yield strength test is not just a technical procedure; it’s a vital part of ensuring the safety and integrity of structures we rely on every day. By understanding the methods, properties, and standards surrounding yield strength, professionals can make better choices in material selection. This ultimately leads to safer buildings, bridges, and products that stand the test of time.

Steel Yield Strength Test Cost

Understanding the costs associated with steel yield strength testing is crucial for budgeting in construction and manufacturing projects. Why? Because these tests are not just a box to tick; they ensure safety and reliability in materials. Imagine building a bridge with weak steel. It could lead to catastrophic failures. So, let’s break down what influences these costs.

First off, the type of test you choose plays a significant role. Common methods like the tensile test or yield point test come with varying price tags. Typically, the tensile test is more widely used and may cost between $200 to $500 per sample. This variation depends on factors like the lab’s location and equipment. Some labs might charge more due to advanced technology or specialized staff.

Another factor is the quantity of samples you’re testing. Ordering tests in bulk can lead to discounts. For instance, if you need ten samples tested, some labs might offer a package deal, reducing the cost per test. It’s like buying in bulk at a grocery store—more items often mean better prices.

Don’t forget about additional services that may come into play. Some labs provide detailed reports, including analysis and recommendations. While these reports can be invaluable, they may also add to your overall costs. If you’re just looking for a quick pass or fail, you might not need those extras.

Now, let’s not overlook the location of the testing facility. If you’re in a remote area, shipping costs can add up quickly. Some companies might charge extra for transportation, especially if they need to send someone to collect samples. It’s always wise to consider these logistics when budgeting.

In summary, here’s a quick look at factors influencing the costs of steel yield strength tests:

- Type of Test: Different tests have different costs.

- Quantity: More samples can lead to discounts.

- Additional Services: Detailed reports can increase costs.

- Location: Shipping and transportation can add to expenses.

Being aware of these factors can help you make informed decisions. After all, the goal is to ensure that the steel you’re using meets the necessary strength requirements without breaking the bank. So, when planning your next project, keep these cost considerations in mind. They might just save you from unexpected financial surprises down the road.

Steel Yield Strength Test Methods

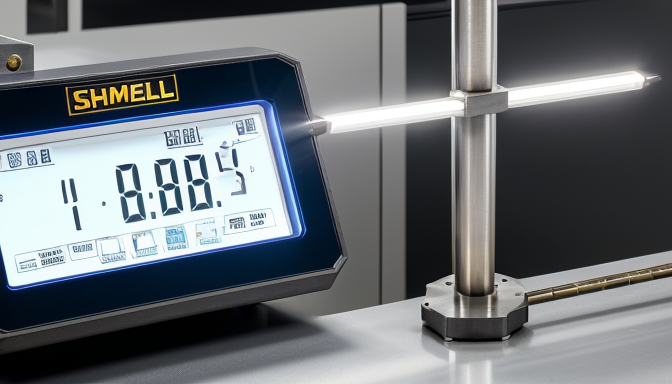

The steel yield strength test is a vital procedure in metallurgy and engineering. It tells us how much stress a steel material can handle before it starts to deform permanently. But how do we actually measure this? Let’s dive into the most common testing methods used today.

First up is the Tensile Test. This method is like stretching a rubber band until it snaps. In this test, a sample of steel is pulled until it breaks. We measure the force applied and the elongation that occurs. This data helps us determine the yield strength. The beauty of the tensile test? It provides a clear picture of how the material behaves under stress. It’s widely accepted and gives reliable results.

Next, we have the Compression Test. Instead of pulling, we’re pushing here. This test is especially useful for materials that are expected to bear loads without bending, like steel beams in buildings. The sample is compressed until it deforms. The results can show us how the material will perform under real-world conditions. It’s like checking how a sponge holds up when you press it down.

Another method worth mentioning is the Bend Test. In this approach, a steel sample is bent to a specific angle. The key here is to see if the material can return to its original shape or if it stays bent. This method helps us understand the ductility of the steel. If it bends but doesn’t break, that’s a good sign! It means the steel can handle some stress without failing.

Now, let’s talk about the Hardness Test. This is a bit different. Instead of measuring how much stress the steel can take, we’re measuring how resistant it is to deformation. Various hardness testing methods exist, such as Rockwell and Brinell tests. These methods involve pressing a hard object into the steel and measuring how deep it goes. The harder the steel, the less it deforms. This test is essential for applications where wear and tear are a concern.

Lastly, we have the Impact Test. This test measures how much energy a steel sample can absorb before it fractures. It’s crucial for materials used in environments where sudden impacts occur, like in construction or automotive industries. Imagine a steel beam getting hit by a falling object; this test helps predict how it will react.

To summarize, here’s a quick comparison of these methods:

| Test Method | Type of Stress | Purpose |

|---|---|---|

| Tensile Test | Tension | Measures yield strength and ductility |

| Compression Test | Compression | Evaluates performance under load |

| Bend Test | Bending | Assesses ductility |

| Hardness Test | Surface Deformation | Measures wear resistance |

| Impact Test | Dynamic Load | Tests energy absorption |

In conclusion, each of these methods has its own strengths and weaknesses. Choosing the right one depends on the specific requirements of your project. Understanding these methods is crucial for anyone working with steel. After all, the strength of your structure relies heavily on the quality of the materials used!

Steel Yield Strength Test Properties

The properties of steel yield strength are crucial to understanding how steel behaves under stress. Yield strength is essentially the point at which steel begins to deform permanently. Imagine bending a paperclip. At first, it bends easily, but if you bend it too far, it won’t return to its original shape. This is similar to what happens with steel. Knowing its yield strength helps engineers decide how much load steel can handle before it loses its shape.

One of the key characteristics of yield strength is its dependence on various factors, including the composition of the steel and the method of production. For instance, carbon content plays a significant role. Higher carbon levels can increase yield strength but may reduce ductility, making the steel more brittle. Conversely, lower carbon content often results in more flexible steel, which is beneficial in applications where bending is required.

Another important factor is the temperature. Steel behaves differently at various temperatures. When it’s heated, it can become more malleable, which is why blacksmiths can shape it easily. However, in colder environments, steel can become less ductile, increasing the risk of fractures. This temperature sensitivity is vital for projects in extreme climates, where material performance can be compromised.

Additionally, the grain structure of steel influences its yield strength. Steel is made up of tiny crystals called grains. The arrangement and size of these grains can either strengthen or weaken the material. For example, finer grains usually enhance strength. This is why processes like quenching and tempering are used in steel production. They alter the grain structure to improve performance.

To give you a clearer picture, here’s a simple table summarizing the main properties affecting yield strength:

| Property | Effect on Yield Strength |

|---|---|

| Carbon Content | Higher carbon increases strength but decreases ductility. |

| Temperature | Higher temperatures can increase malleability; lower temperatures can increase brittleness. |

| Grain Structure | Finer grains generally enhance yield strength. |

Understanding these properties is not just an academic exercise; it’s essential for real-world applications. When engineers select materials for construction, they must consider how steel will perform under expected loads and environmental conditions. This knowledge helps ensure safety and durability in structures like bridges, buildings, and machinery.

In summary, the properties of steel yield strength are fundamental to its performance in various applications. By grasping these concepts, engineers and metallurgists can make informed decisions that impact safety and efficiency in their projects. So, the next time you see a steel structure, remember the science behind its strength!

Steel Yield Strength Test Standards

When it comes to steel yield strength testing, adhering to established standards is not just a formality; it’s a necessity. These standards ensure that the testing process is accurate, reliable, and consistent across various applications. Think of it like following a recipe in cooking. If you skip steps or use the wrong ingredients, the dish can turn out poorly. Similarly, in metallurgy, using recognized standards ensures that the results are trustworthy.

There are several key organizations that set these standards. The most notable include:

- ASTM International – Known for its comprehensive standards, ASTM provides guidelines for various materials, including steel.

- ISO (International Organization for Standardization) – ISO standards are globally recognized and help ensure quality and safety.

- EN (European Norms) – These standards are crucial for projects within Europe, focusing on safety and performance.

Each of these organizations has specific guidelines that detail how to conduct yield strength tests. For instance, ASTM E8/E8M outlines the standard test methods for tension testing of metallic materials. This standard is widely used in laboratories to determine the yield strength of steel. Following such guidelines helps ensure that all tests are performed under the same conditions, which is vital for comparing results.

Moreover, these standards also dictate the conditions under which tests should be performed. Factors like temperature, humidity, and specimen preparation can greatly affect the outcome. Just as a musician must tune their instrument before a performance, metallurgists must ensure that their testing environment meets the required standards. This attention to detail helps in achieving accurate and reliable results.

Understanding these standards is especially important for professionals in the construction and manufacturing industries. They rely on the integrity of steel to support structures and products. If the yield strength is not tested according to recognized standards, it can lead to catastrophic failures or costly mistakes. Imagine building a bridge with subpar materials. The consequences could be dire.

In conclusion, the importance of steel yield strength test standards cannot be overstated. They provide a framework for consistency, reliability, and safety in testing practices. By adhering to these standards, professionals can ensure that they are making informed decisions based on accurate data, ultimately safeguarding their projects and investments.

Frequently Asked Questions

- What is steel yield strength?

Steel yield strength is the amount of stress that a steel material can withstand before it starts to deform permanently. It’s a crucial property that helps engineers determine how much load a structure can handle without compromising its integrity.

- Why is yield strength testing important?

Yield strength testing is vital because it ensures that materials used in construction and manufacturing meet safety and performance standards. By knowing the yield strength, professionals can make informed decisions about material selection, ensuring structures are safe and reliable.

- What methods are used for yield strength testing?

Common methods for testing yield strength include the tensile test, where a sample is pulled until it breaks, and the compression test, which applies pressure to the material. Each method has its own advantages, depending on the type of steel and the specific requirements of the project.

- How much does yield strength testing cost?

The cost of yield strength testing can vary widely based on factors like the testing method, the type of steel, and the complexity of the project. Generally, it’s essential to budget for these tests to avoid unexpected expenses during construction or manufacturing.

- What standards govern yield strength testing?

There are several standards that govern yield strength testing, such as ASTM and ISO standards. These guidelines ensure consistency and reliability in testing practices, which is crucial for maintaining quality in engineering and manufacturing processes.

- How do I choose the right testing method?

Choosing the right testing method depends on various factors, including the material type, project requirements, and available resources. Consulting with a metallurgy expert can help you select the most appropriate method for your specific needs.

- Can yield strength change over time?

Yes, yield strength can change due to factors like aging, environmental conditions, and the material’s history of stress and strain. Regular testing can help monitor these changes and ensure materials remain safe for use.