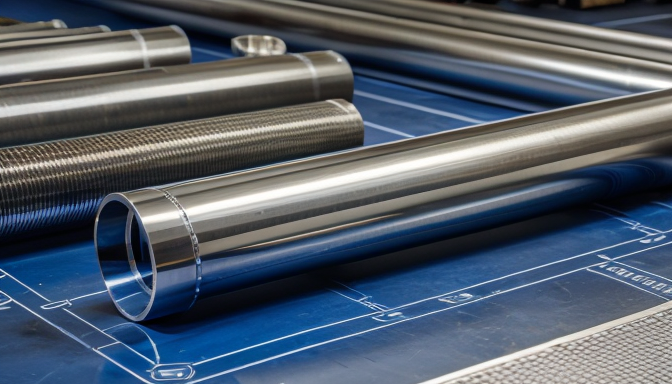

When it comes to transporting water, steel water pipes are a popular choice. But why? Well, they offer a blend of strength, durability, and versatility that few materials can match. Imagine trying to carry water through a flimsy pipe. Not a good idea, right? Steel pipes are robust and built to last, making them ideal for various applications, from municipal water systems to industrial uses.

In this article, we’ll dive into the nitty-gritty of steel water pipes. We’ll explore their price, weight, properties, and sizes, providing insights that are valuable for both professionals and everyday consumers. Understanding these aspects can help you make informed decisions, whether you’re planning a large-scale project or just need a new pipe for your home.

So, what’s the deal with the pricing? The cost of steel water pipes can vary widely based on several factors, including the type of steel, market demand, and even the thickness of the pipe. If you’re on a budget, knowing how to navigate these factors can save you a pretty penny. And let’s not forget about weight! The weight of these pipes can impact transportation and installation. Heavier pipes might require more support and careful handling, which can add to your overall costs.

Another important aspect is the unique properties of steel water pipes. They are known for their corrosion resistance and tensile strength. This means they can withstand harsh environments and heavy pressures without easily breaking down. This is a big deal, especially in places where pipes are exposed to elements that could cause damage. Think of it like wearing a raincoat in a storm; it keeps you safe and dry!

Lastly, let’s talk sizes. Steel water pipes come in various dimensions to fit different needs. Choosing the right size is crucial. A pipe that’s too small won’t deliver enough water, while one that’s too large can be overkill and costly. It’s all about finding that sweet spot. If you’re unsure, consulting with a professional can help you make the right choice.

In conclusion, steel water pipes are not just tubes for transporting water; they are essential components that ensure efficiency and reliability in water systems. Whether you’re a contractor or a homeowner, understanding their price, weight, properties, and sizes will empower you to make better choices. So, let’s get into the details!

Steel Water Pipe Price

Understanding the pricing of steel water pipes is crucial for anyone involved in construction or plumbing projects. Why? Because the cost can significantly impact your budget. Prices can vary widely based on several factors. For instance, the size, thickness, and even the supplier can all play a role.

Typically, the cost of steel water pipes ranges from $1 to $10 per foot. However, prices can fluctuate based on market demand and the quality of the material. For example, a high-grade steel pipe might cost more but offer better durability and longevity. It’s important to weigh these factors when making a purchase.

Here are some key factors that influence the price:

- Material Quality: Higher quality steel generally costs more, but it can save you money in the long run due to its durability.

- Size: Larger pipes require more material, which increases the price.

- Thickness: Thicker pipes can handle more pressure, but they also cost more to produce.

- Market Trends: Prices can rise or fall based on supply and demand. Keeping an eye on market trends can help you buy at the right time.

To find the best prices, consider shopping around. Get quotes from multiple suppliers. Sometimes, buying in bulk can lead to significant savings. Don’t hesitate to negotiate. Many suppliers are willing to work with you on price, especially for larger orders.

In conclusion, knowing the factors that affect the price of steel water pipes can help you make informed decisions. Whether you’re a professional or a DIY enthusiast, being savvy about pricing can save you money and ensure you get the right materials for your project.

Steel Water Pipe Weight

The weight of steel water pipes is an important factor that can influence many aspects of a project. Whether you’re a contractor, engineer, or simply a homeowner, understanding how weight affects transportation and installation is crucial. You might wonder, why does it matter? Well, heavier pipes can be more challenging to handle, and that can impact labor costs and the equipment needed for installation.

Steel pipes are available in various sizes and thicknesses, which directly affects their weight. For instance, a larger diameter pipe will naturally weigh more than a smaller one. But it’s not just the diameter that counts; the wall thickness plays a significant role too. A thicker wall means a heavier pipe. To give you a clearer picture, let’s look at a simple table comparing different sizes and their approximate weights:

| Pipe Diameter (inches) | Wall Thickness (inches) | Weight (lbs/ft) |

|---|---|---|

| 2 | 0.154 | 5.79 |

| 4 | 0.237 | 11.99 |

| 6 | 0.280 | 18.97 |

| 8 | 0.322 | 27.90 |

As you can see, the weight increases significantly with both diameter and wall thickness. This increase can affect how many pipes you can transport at once. Imagine trying to lift a 20-foot section of a heavy pipe. It’s no easy feat! You need the right tools and enough manpower to get the job done safely.

Moreover, when it comes to installation, the weight of the pipes can dictate the type of support structures you need. Heavier pipes require more robust supports to prevent sagging or bending over time. This means additional costs in materials and labor. So, it’s not just about picking the right pipe; it’s about considering how its weight will impact your entire project.

In conclusion, understanding the weight of steel water pipes is essential. It affects everything from transportation to installation and even long-term maintenance. Always consider the weight when planning your project. It can save you time, money, and headaches down the road. So, the next time you’re selecting pipes, remember: weight matters!

Steel Water Pipe Properties

When it comes to steel water pipes, understanding their unique properties is key. These pipes are not just hollow tubes; they are engineered to withstand various challenges in the water distribution system. For instance, their corrosion resistance is a standout feature. Unlike other materials, steel pipes can be treated to resist rust and degradation, making them ideal for long-term use in harsh environments.

Another important property is their tensile strength. Steel pipes can endure significant pressure without breaking. This characteristic is crucial, especially in high-pressure applications. Think of it like a strong bridge holding up heavy traffic. If the bridge can’t handle the load, it’s not safe. Similarly, if a water pipe can’t handle the pressure, it can lead to leaks or bursts.

Durability is another feather in the cap of steel water pipes. They are designed to last for decades, even in challenging conditions. This longevity means fewer replacements and less maintenance, which ultimately saves money. Imagine having a reliable friend who always shows up when you need them; that’s what a durable steel water pipe does for your water system.

Moreover, steel pipes have a high resistance to impact. This means they can withstand physical shocks, which is especially important during transportation and installation. Picture a delivery truck hitting a bump. If the pipes are made of a fragile material, they could crack. But with steel, they are more likely to arrive intact, ready for installation.

Additionally, steel water pipes can be customized in terms of thickness and diameter. This flexibility allows for a wide range of applications. Whether you need a pipe for a small residential project or a large industrial system, there’s a steel option that fits your needs. Here’s a quick overview:

| Property | Description |

|---|---|

| Corrosion Resistance | Ability to withstand rust and degradation |

| Tensile Strength | Can handle significant pressure without breaking |

| Durability | Lasts for decades, reducing replacement costs |

| Impact Resistance | Withstands physical shocks during transport and installation |

In conclusion, the properties of steel water pipes make them a top choice for various applications. Their corrosion resistance, tensile strength, and durability ensure they perform well under pressure and in tough conditions. So, whether you’re a contractor or a homeowner, knowing these properties can help you make informed decisions about your water system.

Steel Water Pipe Sizes

When it comes to steel water pipes, size truly matters. Choosing the right size can make or break your project. Think about it: a pipe too small might not carry enough water, while one that’s too large can lead to unnecessary costs and complications. So, how do you navigate this maze of sizes?

Steel water pipes are available in a variety of dimensions, tailored to meet different needs. The most common sizes range from 2 inches to 48 inches in diameter. But it’s not just about the diameter; the thickness of the pipe also plays a vital role. Thicker pipes can handle higher pressure, making them ideal for industrial applications, while thinner pipes might suffice for residential use.

To make things clearer, let’s break down some standard sizes:

| Diameter (inches) | Common Uses |

|---|---|

| 2 | Residential plumbing |

| 4 | Irrigation systems |

| 6 | Fire protection systems |

| 12 | Municipal water supply |

| 24 | Industrial applications |

Now, you might wonder: how do you choose the right size? Here are a few tips:

- Assess your needs: Consider the volume of water required.

- Check local regulations: Some areas have specific requirements.

- Consult with professionals: They can provide insights based on experience.

Imagine you’re trying to water your garden. A 2-inch pipe might do the trick if you have a small plot. But if you’re managing a large farm, you’d need something larger, maybe even a 12-inch pipe. It’s all about understanding the scale of your project.

In conclusion, selecting the right size for your steel water pipe is crucial for efficiency and cost-effectiveness. Whether you’re a seasoned professional or a DIY enthusiast, knowing the ins and outs of pipe sizes can save you time, money, and a whole lot of hassle. So, the next time you’re faced with this choice, remember: size does matter!

Frequently Asked Questions

- What are the main benefits of using steel water pipes?

Steel water pipes are renowned for their durability and strength. They can withstand high pressure and are resistant to deformation, making them ideal for various applications. Additionally, their corrosion resistance ensures a longer lifespan compared to other materials, ultimately saving you money on replacements and repairs.

- How do I determine the right size of steel water pipe for my project?

Choosing the right size of steel water pipe depends on several factors, including flow rate, pressure requirements, and the application. It’s essential to consult with a professional or refer to industry standards to ensure you select a pipe that meets your needs without compromising performance.

- What factors influence the price of steel water pipes?

The price of steel water pipes can vary based on factors such as material quality, pipe size, and market demand. Additionally, fluctuations in steel prices and transportation costs can also impact the overall pricing. It’s advisable to compare quotes from multiple suppliers to find the best deal.

- Are steel water pipes heavy, and how does that affect installation?

Yes, steel water pipes can be quite heavy, which can pose challenges during transportation and installation. Proper handling equipment and techniques are essential to ensure safety and efficiency. It’s important to factor in the weight when planning your project to avoid any unnecessary complications.

- Can steel water pipes be used for residential plumbing?

Absolutely! Steel water pipes are suitable for residential plumbing, especially in applications requiring high strength and durability. However, it’s important to consider local building codes and regulations, as some areas may have specific requirements for plumbing materials.