is an essential component in modern construction. It’s like the backbone of a building, providing strength and support where it matters most. Imagine trying to build a house without a solid foundation. It just wouldn’t hold up. That’s the role of steel mesh in concrete structures. It keeps everything together, ensuring durability and safety.

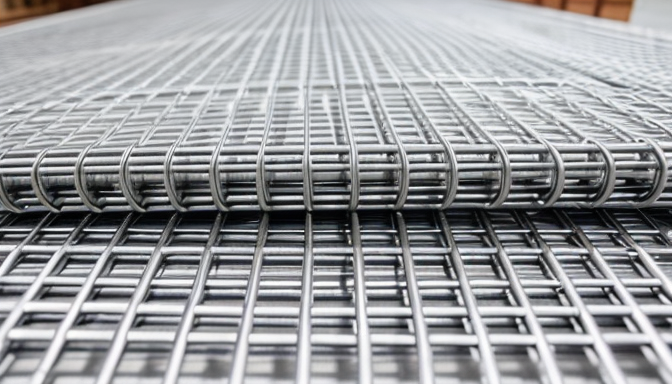

So, what exactly is it? Steel reinforcing mesh is made from high-quality steel wires that are welded together in a grid pattern. This grid provides a uniform distribution of strength throughout the concrete. When concrete is poured over this mesh, it bonds with the steel, creating a composite material that is much stronger than concrete alone. This combination is vital for structures that need to withstand heavy loads and resist cracking.

But why is it so significant? Well, without steel mesh, concrete can crack and fail under stress. Think of it like a well-balanced meal. You need a variety of nutrients to stay healthy. Similarly, concrete needs the support of steel to perform at its best. This is particularly important in areas prone to earthquakes or heavy winds, where buildings must be designed to flex and bend without breaking.

In addition to its structural benefits, steel reinforcing mesh also plays a role in cost efficiency. By using this mesh, builders can reduce the overall amount of concrete needed for a project, which can lead to significant savings. It’s a win-win situation: stronger buildings and lower costs. However, the price of steel mesh can vary based on several factors, which we’ll explore in the next section.

In summary, steel reinforcing mesh is not just a construction material; it’s a vital player in the building game. Its ability to enhance the strength of concrete makes it indispensable in modern architecture. When you see a sturdy building, remember that behind its strength lies the mesh that holds it all together. Understanding its importance can help anyone involved in construction make better choices for their projects.

Steel Reinforcing Mesh Price

When it comes to steel reinforcing mesh, understanding its price is crucial. Why? Because it directly affects your project’s budget. The price can vary significantly based on several factors. First, let’s talk about market trends. Prices can fluctuate with demand. If construction is booming, prices might rise. Conversely, in a slow market, you might find better deals.

Next, consider material costs. The price of raw steel plays a massive role. If steel prices go up, so does the cost of reinforcing mesh. It’s like a seesaw; when one side goes up, the other follows. Additionally, regional variations can impact pricing. In some areas, transportation costs might be higher, leading to increased prices. So, always check local suppliers for the best rates.

Now, let’s break down some key factors that influence the price of steel reinforcing mesh:

- Thickness and Size: Thicker and larger meshes usually cost more.

- Type of Steel: Different grades of steel can affect the price.

- Supplier and Location: Local suppliers may offer better prices than those far away.

To give you a clearer picture, here’s a simple table showing average prices based on size and thickness:

| Size (mm) | Thickness (mm) | Average Price ($/m²) |

|---|---|---|

| 1500 x 3000 | 5 | 2.50 |

| 2000 x 4000 | 8 | 3.75 |

| 3000 x 6000 | 10 | 5.00 |

As you can see, the price can vary based on size and thickness. It’s essential to factor these elements into your budget. When planning a project, always get quotes from multiple suppliers. This way, you can compare prices and ensure you’re getting the best deal.

In summary, understanding the price of steel reinforcing mesh is key to making informed decisions. Keep an eye on market trends, material costs, and regional pricing. By doing so, you’ll not only save money but also ensure your project runs smoothly without unexpected costs.

Steel Reinforcing Mesh Weight

The weight of steel reinforcing mesh is more than just a number; it plays a critical role in construction. Why? Because every project has its own unique requirements. From the foundation of a skyscraper to the walls of a cozy home, understanding the weight helps in making crucial decisions.

So, how is the weight determined? It’s calculated based on the mesh’s dimensions and the thickness of the steel bars. Typically, the weight can vary depending on the size and spacing of the wires used in the mesh. For instance, a denser mesh will weigh more than a lighter one. This is important when considering transportation logistics. Imagine trying to move a heavy load on a small truck. It’s not just impractical; it can lead to serious issues.

Here’s a quick look at how the weight of steel reinforcing mesh can influence construction:

- Structural Calculations: Engineers need to know the weight to ensure the building can support the load.

- Transportation Costs: Heavier mesh can increase shipping fees, impacting the overall budget.

- Handling and Installation: Lighter mesh is easier to handle, reducing labor time and costs.

To give you a clearer picture, let’s break down the weight of different mesh sizes. Below is a simple table showing the approximate weights for common sizes:

| Mesh Size (mm) | Weight (kg/m²) |

|---|---|

| 6 x 6 | 4.5 |

| 8 x 8 | 5.2 |

| 10 x 10 | 6.0 |

| 12 x 12 | 7.5 |

This table provides a quick reference, but remember, the actual weight may vary based on the manufacturer and specific project requirements. In construction, every detail matters. The right weight can make the difference between a safe structure and a potential disaster.

In conclusion, understanding the weight of steel reinforcing mesh is essential for anyone involved in construction. It’s not just about numbers; it’s about safety, efficiency, and cost-effectiveness. So, the next time you’re planning a project, keep this in mind. It could save you time and money in the long run!

Steel Reinforcing Mesh Properties

When it comes to construction, the materials we choose can make or break a project. One such material that stands out is steel reinforcing mesh. This mesh is not just a simple grid; it plays a crucial role in enhancing the strength and durability of concrete structures. But what makes it so special? Let’s dive into its unique properties.

First off, one of the most remarkable characteristics of steel reinforcing mesh is its strength. This strength comes from the high tensile strength of steel, which allows it to withstand significant loads. Think of it like a backbone for concrete. Just as our spine supports our body, the mesh supports the concrete, ensuring it holds up under pressure. Without this support, concrete can crack and fail, leading to costly repairs and safety hazards.

Another important property is flexibility. While steel is known for its strength, it also has the ability to bend without breaking. This flexibility is essential in construction, especially in areas prone to seismic activity. Imagine a building swaying gently during an earthquake. The steel mesh allows the concrete to move slightly without cracking. This adaptability can be the difference between a standing structure and a collapsed one.

Moreover, steel reinforcing mesh is designed to be corrosion-resistant. This is vital because exposure to moisture can weaken steel over time. Many manufacturers apply protective coatings to enhance this property, ensuring that the mesh lasts longer even in harsh conditions. It’s like putting on a raincoat before heading out in a storm—you’re protecting something valuable from the elements.

Now, let’s talk about the bonding properties. Steel reinforcing mesh has excellent bonding capabilities with concrete. When poured, the concrete envelops the mesh, creating a solid bond that enhances the overall strength of the structure. This bond is crucial because it allows the mesh to work effectively with the concrete, distributing loads evenly across the surface.

In addition to these properties, steel reinforcing mesh comes in various configurations. This means that it can be tailored to meet specific project requirements. Whether you need a heavy-duty mesh for a bridge or a lighter option for a residential building, there’s a type that fits the bill. Here’s a quick overview of some common configurations:

| Mesh Type | Tensile Strength (MPa) | Common Applications |

|---|---|---|

| Welded Wire Mesh | 400-500 | Slabs, walls |

| Reinforcing Bar Mesh | 500-600 | Foundations, beams |

| Composite Mesh | 600+ | High-load applications |

In summary, the properties of steel reinforcing mesh—its strength, flexibility, corrosion resistance, and bonding capabilities—make it an essential component in modern construction. By understanding these characteristics, builders can make informed decisions that ensure the longevity and safety of their projects. So, next time you see a concrete structure, remember the hidden hero within: steel reinforcing mesh.

Steel Reinforcing Mesh Sizes

When it comes to construction, the size of steel reinforcing mesh is not just a detail; it’s a crucial factor that can influence the entire project. Think of it like choosing the right size of a puzzle piece. If it doesn’t fit, the whole picture falls apart. Steel reinforcing mesh comes in various sizes, each tailored for specific applications. Understanding these sizes can help builders ensure that they are using the right materials for their projects.

Generally, steel reinforcing mesh is available in sheets or rolls. The most common sizes for sheets are:

| Size (mm) | Mesh Spacing (mm) | Weight (kg/m²) |

|---|---|---|

| 2000 x 6000 | 150 x 150 | 2.5 |

| 2400 x 1200 | 200 x 200 | 3.0 |

| 3000 x 6000 | 100 x 100 | 4.0 |

These sizes are just a snapshot of what’s available. Builders often select their mesh based on the specific requirements of their project. For instance, larger mesh sizes might be used for heavy-duty applications like highways or bridges, where strength is paramount. On the other hand, smaller sizes are often sufficient for residential buildings or smaller structures.

But how do you choose the right size? It boils down to a few key factors:

- Project Specifications: Always refer to the engineering plans.

- Load Requirements: Consider what the structure needs to support.

- Local Building Codes: Compliance is crucial!

Another important aspect to consider is the mesh spacing. This refers to the distance between the wires in the mesh. The spacing can significantly affect the strength and flexibility of the reinforced concrete. Closer spacing offers more support but can be more expensive and heavy.

In conclusion, when selecting steel reinforcing mesh sizes, it’s essential to think about the specific needs of your project. Whether you’re working on a small home or a large infrastructure project, the right size can make all the difference. So, next time you find yourself in the hardware store or a supplier’s yard, remember: choosing the right size is not just about fitting in; it’s about building a solid foundation for success.

Frequently Asked Questions

- What is steel reinforcing mesh?

Steel reinforcing mesh is a grid-like structure made from steel bars or wires, used to reinforce concrete in construction projects. It provides strength and stability, ensuring that the concrete can withstand various loads and stresses.

- How does the price of steel reinforcing mesh vary?

The price of steel reinforcing mesh can fluctuate based on several factors, including market demand, the cost of raw materials, and regional pricing differences. Understanding these factors can help you make a more informed purchasing decision.

- What is the importance of the weight of steel reinforcing mesh?

The weight of steel reinforcing mesh is crucial for structural calculations and logistics. Knowing the weight helps in determining how much material is needed for a project and aids in planning transportation and installation.

- What properties make steel reinforcing mesh effective?

Steel reinforcing mesh is known for its impressive strength and flexibility. These properties allow it to effectively distribute loads within concrete, preventing cracks and ensuring longevity in various construction applications.

- What sizes of steel reinforcing mesh are available?

Steel reinforcing mesh comes in various sizes to suit different construction needs. Common sizes include 6×6 inches and 4×4 inches, but the choice depends on specific project requirements and structural designs.

- Can I use steel reinforcing mesh for all types of concrete projects?

While steel reinforcing mesh is versatile and suitable for many concrete applications, it’s essential to choose the right type and size based on the specific demands of your project. Always consult with a professional to ensure proper usage.