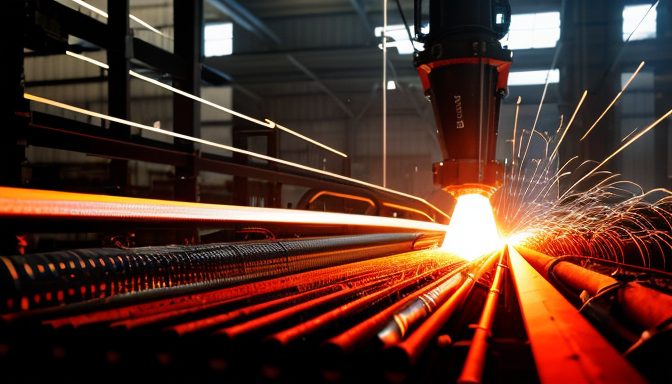

When it comes to shaping steel pipes with precision, laser cutting is a game changer. Imagine slicing through metal like a hot knife through butter. That’s how effective this technology is! Steel pipe laser cutting is not just about aesthetics; it’s about efficiency and accuracy. This process uses a high-powered laser to cut through steel, allowing for intricate designs and exact measurements. It’s widely used in various industries, from construction to automotive, due to its versatility.

Why choose laser cutting? Well, for starters, it offers a clean edge. No rough spots. No need for additional finishing. This means less time spent on post-processing, which can save money and time. Plus, the flexibility of laser cutting allows for customization. You can create unique shapes and sizes that fit your specific needs. Whether you need a simple cut or a complex design, laser cutting can handle it.

Now, you might be wondering about the cost. Understanding the expenses involved is crucial for any project. Factors like the thickness of the steel, the complexity of the design, and the type of laser used can all influence pricing. Generally, though, the benefits of precision cutting often outweigh the initial costs. Think of it this way: investing in high-quality cuts can lead to fewer errors down the line, which saves you money in the long run.

Another essential aspect is the weight capacity of laser-cut steel pipes. This is critical when it comes to structural integrity. If you’re working on a project that requires support beams, knowing how much weight your pipes can handle is vital. Overloading can lead to catastrophic failures. So, always check the specifications before making your selection.

As for techniques, there are several methods of laser cutting, each with its own perks. For instance, CO2 lasers are great for cutting thick materials, while fiber lasers excel at cutting thin sheets. Understanding which technique suits your project can make a big difference in efficiency and quality. It’s like choosing the right tool for a job; using a hammer for a nail and a saw for wood, right?

Lastly, let’s talk about sizes. Steel pipes come in various sizes, and knowing the standard dimensions can help you make informed decisions. Common sizes range from small diameter pipes to large ones, but customization is always an option. If you need something specific, many suppliers can accommodate your requests. Just remember, the size you choose can impact the overall design and functionality of your project.

In conclusion, steel pipe laser cutting is an essential process that combines precision, efficiency, and flexibility. Whether you’re a contractor, engineer, or DIY enthusiast, understanding the ins and outs of this technology can help you make better choices for your projects. So, next time you think about cutting steel, remember the power of laser cutting!

Steel Pipe Laser Cutting Cost

Understanding the costs associated with steel pipe laser cutting is essential for budgeting and project planning. This process isn’t just about cutting metal; it involves various factors that can influence the final price. When you think about it, how often do we overlook the details that can make a big difference in our project’s bottom line? Let’s dive into the key elements that affect pricing.

First, the type of steel used plays a significant role. Different grades of steel have varying costs. For example, mild steel is generally more affordable than stainless steel. Additionally, the thickness of the pipe can impact the price. Thicker pipes require more energy and time to cut, which can increase costs. So, if you’re working on a tight budget, consider the thickness carefully.

Another important factor is the complexity of the design. Simple cuts are usually cheaper than intricate designs. If your project requires detailed patterns, be prepared for a higher price tag. Think of it like ordering a cake. A plain vanilla cake costs less than a multi-tiered, decorated masterpiece. The more detail you want, the more you’ll pay.

Also, the quantity of pipes you need will affect the overall cost. Bulk orders often come with discounts. If you’re planning a large project, consider ordering in larger quantities to save money. It’s like buying in bulk at a grocery store; the more you buy, the less you pay per item.

Let’s not forget about the location of the service provider. Prices can vary significantly depending on where you are. Urban areas might have higher costs due to increased demand and overhead. In contrast, rural areas might offer more competitive pricing. Always shop around to find the best deal.

To give you a clearer picture, here’s a simple table summarizing the factors affecting cost:

| Factor | Impact on Cost |

|---|---|

| Type of Steel | Varies significantly; mild is cheaper than stainless |

| Thickness of Pipe | Thicker pipes increase cutting time and energy |

| Design Complexity | Intricate designs cost more |

| Quantity | Bulk orders may reduce per-unit cost |

| Location | Urban areas may charge more than rural |

In summary, when planning for steel pipe laser cutting, consider these factors closely. They can make or break your budget. By understanding what influences costs, you can make informed decisions that keep your project on track without breaking the bank. Always remember, a little research goes a long way!

Steel Pipe Laser Cutting Weight Capacity

The weight capacity of steel pipes is a crucial factor when considering laser cutting. Why? Because the integrity of any structure depends heavily on the materials used. If the weight capacity is not adequate, the entire project can be at risk. Think of it like building a house on sand. It might look good on the surface, but one good storm, and it could all come crashing down.

When we talk about weight capacity, we’re looking at how much load a steel pipe can handle without compromising its strength. This is where laser cutting comes into play. Laser cutting allows for precise cuts that can enhance the structural properties of the pipe. It ensures that the weight distribution is even, which is vital for applications in construction, automotive, and manufacturing industries.

So, what affects the weight capacity of laser-cut steel pipes? Several factors come into play:

- Material Thickness: Thicker pipes can usually carry more weight. However, they can also be more challenging to cut.

- Pipe Diameter: Larger diameters can support heavier loads, but they may require more powerful lasers for cutting.

- Pipe Shape: Different shapes, like rectangular or circular, have unique weight capacities based on their geometry.

For instance, a standard steel pipe with a diameter of 6 inches and a thickness of 0.5 inches might have a weight capacity of around 5,000 pounds. However, if you increase the thickness to 1 inch, that capacity could jump to 10,000 pounds. It’s all about finding the right balance!

Moreover, understanding the weight capacity is not just about numbers; it’s about safety and reliability. In industries like construction, using pipes that can’t handle the load can lead to catastrophic failures. Imagine a construction beam collapsing because the steel pipe couldn’t support it. That’s why engineers spend so much time calculating these factors.

In conclusion, when considering steel pipe laser cutting, always keep the weight capacity in mind. It’s not just a technical detail; it’s a matter of ensuring the safety and longevity of your project. By understanding how weight affects your choices, you can make informed decisions that lead to successful outcomes. After all, nobody wants to be the one responsible for a project that didn’t hold up!

Steel Pipe Laser Cutting Techniques

When it comes to steel pipe laser cutting, there are several techniques that stand out. Each method has its own strengths, making it essential to choose the right one for your project. So, what are these techniques, and how do they work?

First up is the CO2 laser cutting. This method uses a high-powered beam of carbon dioxide to slice through steel. It’s known for its precision and ability to cut through thick materials. If you’re looking for clean edges and intricate designs, this might be the technique for you. However, it can be slower compared to other methods, so keep that in mind.

Next, we have fiber laser cutting. This technique is gaining popularity due to its speed and efficiency. Fiber lasers use a solid-state laser and are particularly effective for cutting thin to medium thickness steel pipes. The energy efficiency is impressive, which can lead to lower operational costs. Plus, the maintenance is minimal, making it a favorite among manufacturers.

Another technique worth mentioning is Nd:YAG laser cutting. This method uses a neodymium-doped yttrium aluminum garnet laser. It’s great for creating small holes and detailed cuts. However, it’s not as commonly used for larger projects, mainly due to its slower cutting speed. But if your project requires precision, Nd:YAG might be the way to go.

Now, let’s talk about the plasma cutting technique. While not strictly a laser method, it’s often compared to laser cutting because of its effectiveness. Plasma cutting uses a high-velocity jet of ionized gas to cut through steel. It’s particularly useful for thick materials and is faster than traditional laser cutting methods. However, the edges might require additional finishing work.

To give you a clearer picture of these techniques, here’s a quick comparison:

| Technique | Material Thickness | Speed | Precision |

|---|---|---|---|

| CO2 Laser Cutting | Thick | Moderate | High |

| Fiber Laser Cutting | Thin to Medium | High | Very High |

| Nd:YAG Laser Cutting | Thin | Low | Very High |

| Plasma Cutting | Thick | Very High | Moderate |

In summary, the choice of technique depends on your specific needs—whether it’s the thickness of the steel, the level of precision required, or the speed of production. Understanding these techniques can help you make informed decisions for your steel pipe projects. After all, the right choice can lead to better results and even cost savings in the long run.

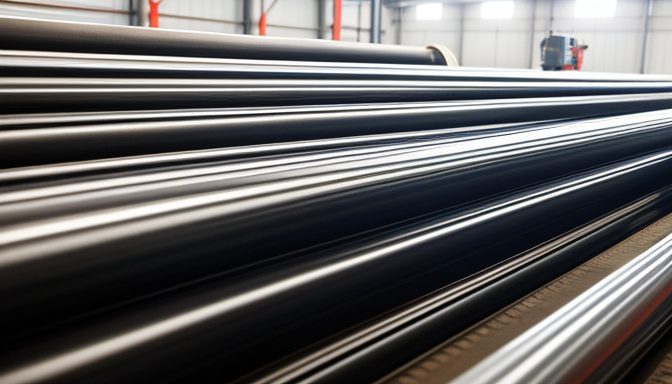

Steel Pipe Laser Cutting Sizes

When it comes to steel pipe laser cutting, size matters. The dimensions of steel pipes can make or break a project. Imagine trying to fit a square peg in a round hole; it just won’t work. The right size ensures not only that your project fits together seamlessly but also that it meets all safety and structural requirements.

Standard sizes for steel pipes vary widely, and understanding these can be crucial for your design choices. Common diameters range from 1 inch to 24 inches, while wall thickness can vary from 0.065 inches to over 0.5 inches. This variability allows for flexibility in applications, from lightweight structures to heavy-duty frameworks.

However, not all projects fit neatly into these standard sizes. Sometimes, you need something a bit more tailored. That’s where customization comes into play. Many manufacturers offer the option to create pipes of specific dimensions, allowing you to get exactly what you need without compromising on quality. This can be a game changer for unique projects where standard sizes just won’t cut it.

Consider this: if you’re working on a construction project, the size of the steel pipes you choose can affect everything from load-bearing capacity to aesthetic appeal. A larger diameter pipe might be necessary for structural support, while a smaller one could be perfect for a decorative railing. The possibilities are endless, but they all start with understanding your size options.

| Pipe Diameter (inches) | Wall Thickness (inches) | Typical Applications |

|---|---|---|

| 1 | 0.065 – 0.120 | Residential plumbing, small furniture |

| 4 | 0.120 – 0.250 | Handrails, light structural support |

| 12 | 0.250 – 0.500 | Heavy-duty construction, industrial applications |

| 24 | 0.500+ | Bridges, large structural frameworks |

In summary, the sizes of steel pipes available for laser cutting can significantly impact your project’s design and functionality. Whether you stick to standard sizes or opt for customized solutions, understanding these options is key. So next time you embark on a project, remember: size isn’t just a number; it’s a critical factor in your success.

Frequently Asked Questions

- What factors influence the cost of steel pipe laser cutting?

The cost of steel pipe laser cutting can vary based on several factors, including the thickness of the pipe, the complexity of the design, the type of laser technology used, and the quantity being cut. Additionally, location and market demand can also play significant roles in pricing.

- What is the weight capacity of laser-cut steel pipes?

The weight capacity of laser-cut steel pipes largely depends on their diameter, wall thickness, and material grade. Generally, engineers must consider these factors to ensure that the pipes can support the intended load without compromising structural integrity.

- What are the common techniques used in steel pipe laser cutting?

Several techniques are employed in steel pipe laser cutting, including fiber laser cutting and CO2 laser cutting. Fiber lasers are known for their efficiency and precision, making them ideal for intricate designs, while CO2 lasers are often used for thicker materials. Each technique has its own set of advantages depending on the application.

- What sizes of steel pipes can be laser cut?

Steel pipes come in a variety of standard sizes, typically ranging from 1 inch to several feet in diameter. Custom sizes can also be produced to meet specific project requirements, allowing for flexibility in design and application.

- What industries commonly use laser-cut steel pipes?

Laser-cut steel pipes are widely used across various industries, including construction, automotive, aerospace, and manufacturing. Their precision and ability to create complex shapes make them ideal for applications such as structural supports, exhaust systems, and custom machinery parts.