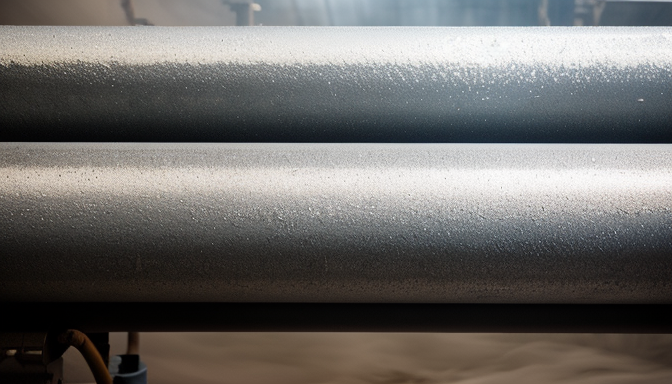

When it comes to steel pipes and profiles, sandblasting is a crucial process. It’s like giving your pipes a fresh start. Imagine scrubbing away years of grime and rust. That’s exactly what sandblasting does. It cleans, prepares, and enhances the surface of steel, making it ready for further treatment or use. But why is this important? Well, a clean surface can lead to better adhesion of coatings and paints. This means that your steel pipes will not only look good but also last longer.

Now, let’s dive deeper into what sandblasting really involves. The process uses high-pressure air to propel tiny particles, usually sand, against the surface of the steel. This action removes contaminants and creates a rough texture, which is essential for paint or protective coatings to stick. Think of it like preparing a canvas before painting. If the canvas is dirty or uneven, the paint won’t adhere properly. Similarly, steel pipes need that rough surface for optimal performance.

But it’s not just about cleaning. Sandblasting also impacts the structural integrity of the pipes. It can alter their weight, which is a significant factor in many applications. Lighter pipes might be easier to handle and install, but what about their strength? This is where the balance comes into play. Understanding how sandblasting affects both weight and strength is essential for anyone working with steel pipes.

Furthermore, the properties of steel pipes are influenced by sandblasting. The surface finish achieved through this process can enhance the pipes’ durability and resistance to corrosion. A smoother finish can lead to better fluid flow, which is crucial in many industries. So, whether you’re in construction, plumbing, or manufacturing, knowing the benefits of sandblasting can help you make informed decisions.

Different sizes of steel pipes require specific sandblasting techniques. For instance, larger pipes may need more powerful equipment to ensure thorough cleaning, while smaller pipes might require more delicate handling. This variability means that there’s no one-size-fits-all approach. Each project is unique, and understanding the size and type of pipe you’re dealing with can lead to better outcomes.

In summary, sandblasting steel pipes and profiles is not just a routine task. It’s an essential part of ensuring that these materials perform well in their intended applications. From cost considerations to the impact on weight and properties, every aspect plays a role in the overall effectiveness of the process. So next time you look at a steel pipe, remember the journey it went through to get there. It’s more than just metal; it’s a carefully crafted product ready for the challenges ahead.

Steel Pipe Sandblasting Cost

Understanding the costs associated with sandblasting steel pipes is crucial for budgeting. It’s not just about the price tag; several factors come into play. Imagine planning a road trip. You wouldn’t just consider gas prices, right? You’d think about food, lodging, and maybe even unexpected tolls. The same goes for sandblasting.

First off, the material type is a significant factor. Different steel grades can have varying costs. For instance, high-grade stainless steel may require more specialized techniques and materials for sandblasting, which can hike up your expenses. On the other hand, standard carbon steel might be more straightforward and cost-effective.

Next, let’s talk about project size. A larger project often means more time and resources. Think about it: sandblasting a single pipe is different from blasting an entire pipeline. The larger the scale, the more you might expect to pay. You might also need more equipment, which can add to the overall cost.

Then there’s the location. Where you are plays a big role. If you’re in a remote area, transportation costs can increase. Also, local labor rates can vary widely. For example, hiring a contractor in a big city might cost significantly more than in a smaller town. So, always factor in your geographical location when budgeting for sandblasting.

To give you a rough idea, here’s a simple table that breaks down some average costs:

| Pipe Size | Average Cost per Foot | Estimated Time |

|---|---|---|

| 2 inches | $5 – $10 | 1 hour |

| 4 inches | $10 – $15 | 2 hours |

| 6 inches | $15 – $20 | 3 hours |

As you can see, costs can vary widely based on size and time required. But that’s not all. Preparation and cleanup are often overlooked but can also add to the total cost. You wouldn’t want to forget about those details!

In conclusion, when planning for sandblasting steel pipes, it’s essential to consider all these factors. They can significantly impact your budget. So, before diving in, take a moment to assess your needs and gather quotes from different contractors. This way, you can avoid any nasty surprises down the road.

Steel Pipe Sandblasting Weight Impact

When it comes to sandblasting steel pipes, one might not immediately think about weight. But here’s the thing: the sandblasting process can actually alter the weight of steel pipes. How? Well, let’s dive in.

Sandblasting involves shooting abrasive materials at high speeds to clean or prepare the surface of steel pipes. This process removes rust, old paint, and other contaminants. However, it also strips away a thin layer of the pipe itself. As a result, the overall weight of the pipe can change. Imagine peeling an apple; you lose some of its mass, right? The same principle applies here.

Now, you might be wondering, “Is this weight change significant?” The answer is: it depends. The extent of weight loss can vary based on several factors:

- Type of Abrasive Used: Different abrasives have different impacts. Some are gentler, while others are more aggressive.

- Duration of the Sandblasting: The longer the process, the more material is removed.

- Initial Thickness of the Pipe: Thicker pipes may lose more weight compared to thinner ones.

For instance, a standard 6-inch steel pipe might weigh around 40 pounds per foot. If sandblasted aggressively, it could lose a few pounds due to material removal. While that may not sound like a lot, in large-scale projects with hundreds of feet of piping, the weight loss can add up.

But why should we care about this weight change? Well, it can affect transportation and installation. Lighter pipes are easier to handle, but they may also compromise structural integrity if too much material is removed. Think of it like carrying a backpack; if you take out too many items, it becomes lighter, but you might not have everything you need for your journey.

In conclusion, understanding the weight impact of sandblasting on steel pipes is vital. It helps in planning and ensures that the pipes remain strong and reliable. Always consider the balance between cleaning effectiveness and maintaining the pipe’s integrity. After all, you want your pipes to perform well for years to come!

Steel Pipe Sandblasting Properties

When it comes to steel pipe sandblasting, understanding the properties that change during the process is crucial. Sandblasting, or abrasive blasting, is not just about cleaning. It’s about enhancing the performance and longevity of steel pipes. Imagine a rough diamond being polished. That’s what sandblasting does to steel pipes—it transforms them.

One of the key properties affected by sandblasting is the surface finish. A smoother surface can significantly improve the adhesion of coatings and paints. This means that when you apply a protective layer, it sticks better and lasts longer. Think about it: a well-prepared surface is like a good foundation for a house. Without it, everything else could crumble.

Another important property is the structural integrity of the pipes. Sandblasting removes rust, old paint, and other contaminants that can weaken the metal. However, if not done properly, it can also remove too much material, leading to potential weaknesses. It’s like trimming a tree: a little pruning helps it grow, but too much can kill it. Therefore, the technique and pressure used during sandblasting are critical.

Moreover, sandblasting can enhance the adhesion qualities of the pipe surface. A rougher texture created by the blasting process can provide a better grip for coatings. This is particularly important for pipes that will be exposed to harsh environments. Think of it as giving the surface a ‘grip’—like the tread on a tire. The better the grip, the safer and more effective the performance.

Let’s not forget about the cleanliness of the pipes. A clean surface is essential for any application, whether it’s for construction, oil and gas, or manufacturing. Sandblasting ensures that the pipes are free from contaminants that could lead to corrosion or failure down the line. It’s like washing your hands before a meal; you want to ensure everything is clean to avoid problems later.

In summary, the properties of steel pipes after sandblasting can greatly influence their performance. The surface finish, structural integrity, adhesion qualities, and cleanliness are all vital aspects that contribute to the overall effectiveness and durability of the pipes. Understanding these properties can help in making informed decisions about when and how to sandblast steel pipes.

Steel Pipe Sandblasting Sizes

When it comes to sandblasting steel pipes, size matters. Different sizes of pipes require unique approaches to ensure the best results. Think of it like fitting a key into a lock; the right size key opens the door smoothly, while the wrong one can jam it. In the world of sandblasting, using the correct size can mean the difference between a flawless finish and a rough surface.

Steel pipes come in various diameters and lengths, which influence the sandblasting technique used. For instance, smaller pipes might be easier to handle and can be sandblasted in a booth or cabinet. Larger pipes, on the other hand, may need to be sandblasted in an open area or specialized equipment due to their weight and size. If you’re working with a 2-inch diameter pipe, you can use a different method compared to a hefty 24-inch diameter pipe. It’s all about adapting to the size.

Here’s a quick breakdown of how pipe sizes can affect the sandblasting process:

| Pipe Size (Diameter) | Recommended Sandblasting Method | Typical Applications |

|---|---|---|

| 1-4 inches | Handheld or cabinet blasting | Plumbing, small structural components |

| 5-12 inches | Automated blasting systems | Industrial piping, HVAC systems |

| 13-24 inches | Open area blasting | Large infrastructure, oil and gas pipelines |

Each method has its own set of advantages. For smaller pipes, handheld or cabinet blasting allows for precision and control. However, as the size increases, automated systems become more efficient, saving time and labor costs. Open area blasting is often necessary for those larger pipes, but it requires careful planning to manage dust and debris.

Another factor to consider is the length of the pipe. Longer pipes can be cumbersome and may require special fixtures or supports during the blasting process. Imagine trying to sandblast a long, heavy tube while keeping it steady; it’s not easy! Therefore, planning for both diameter and length is crucial to ensure that the sandblasting process runs smoothly.

In conclusion, understanding the sizes of steel pipes and how they influence the sandblasting process is essential for achieving optimal results. Whether you’re working with small plumbing pipes or massive industrial ones, knowing the right approach can save time and enhance the quality of your project. So, next time you think about sandblasting, remember: size isn’t just a number; it’s a game-changer!

Frequently Asked Questions

- What is sandblasting and how does it work?

Sandblasting is a process that involves propelling abrasive materials at high speeds onto a surface, like steel pipes, to clean, smooth, or etch the surface. Imagine it as a powerful shower of tiny particles that strip away dirt, rust, and old paint, leaving a fresh surface ready for further treatment or coating.

- How much does sandblasting steel pipes typically cost?

The cost of sandblasting steel pipes can vary widely based on factors such as the type of material, the size of the project, and your location. On average, you might expect to pay anywhere from $2 to $5 per square foot, but larger projects can sometimes lead to bulk discounts!

- Does sandblasting affect the weight of steel pipes?

Yes, sandblasting can impact the weight of steel pipes. While the weight change might be minimal, the removal of surface contaminants can slightly reduce the overall mass. However, this process primarily focuses on enhancing the surface properties rather than significantly altering weight.

- What properties of steel pipes are improved through sandblasting?

Sandblasting can significantly improve several properties of steel pipes, including surface finish and adhesion qualities. A smoother surface allows for better coating adhesion, which can enhance corrosion resistance and overall durability.

- Are there specific sandblasting techniques for different sizes of steel pipes?

Absolutely! Different sizes of steel pipes require tailored sandblasting techniques. For instance, larger pipes may need more robust equipment and a different angle of approach to ensure an even and thorough blast, while smaller pipes might be treated with more precision.