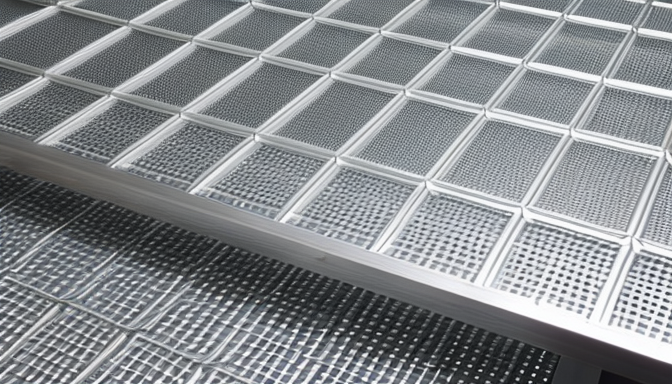

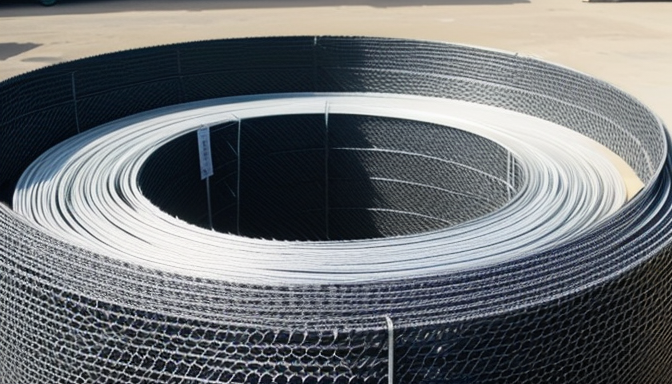

When it comes to construction materials, stands out as a versatile option. It’s like the backbone of many structures, providing support and strength where it’s most needed. But what exactly is steel mesh? Simply put, it’s a grid-like structure made of steel wires. These wires are woven or welded together to create a mesh that can be used in various applications, from concrete reinforcement to fencing.

Imagine trying to build a sturdy house without a solid foundation. That’s where steel mesh comes into play. It’s not just about strength; it also adds flexibility. This makes it easier to work with in different environments. Whether you’re pouring concrete for a sidewalk or creating a barrier for a construction site, steel mesh is your go-to material. Plus, it’s relatively lightweight, which helps in transportation and installation. But hold on! There’s more to it than just being lightweight.

In this article, we’ll explore the ins and outs of steel mesh, including its price, weight, properties, sizes, and applications. Understanding these aspects is crucial for anyone involved in construction or DIY projects. You wouldn’t want to dive into a project without knowing what you’re working with, right?

So, let’s get started on this journey through the world of steel mesh. You might be surprised at how much you can learn about this essential material!

Steel Mesh Price

Understanding the pricing factors of steel mesh is crucial for budgeting construction projects. Prices can vary widely based on several elements. Have you ever wondered what drives these costs? Well, let’s break it down!

First, the material costs play a significant role. The type of steel used, whether it’s mild steel or a higher-grade alloy, can influence the price. Additionally, the fluctuations in the steel market can lead to price changes. For example, if demand spikes due to increased construction activity, you might find yourself paying more. Likewise, when supply is high, prices can drop.

Next, we have the specifications of the mesh itself. The thickness, size of the openings, and overall dimensions can all affect the price. Generally, more complex designs will cost more. For instance, a standard mesh might be cheaper, while a custom size or shape could lead to higher expenses. It’s like buying a plain t-shirt versus a custom-made one; the latter usually costs more.

Here’s a quick overview of how different factors can influence steel mesh pricing:

| Factor | Impact on Price |

|---|---|

| Material Type | Higher-grade steel increases costs |

| Market Demand | Increased demand raises prices |

| Specifications | Custom sizes or designs cost more |

Additionally, it’s important to consider the location of your purchase. Prices can vary from one region to another. If you’re sourcing from a local supplier, you might find better deals compared to national suppliers due to lower shipping costs. Always check multiple vendors to find the best price.

Lastly, don’t forget about bulk purchasing. If you’re buying in large quantities, you might be eligible for discounts. It’s worth asking suppliers about bulk rates. After all, saving a few dollars here and there can add up quickly!

In conclusion, understanding the price of steel mesh involves looking at various factors. From material costs to specifications and location, each element plays a part. So, the next time you’re budgeting for a project, keep these considerations in mind. They can make a significant difference in your overall costs!

Steel Mesh Weight

The weight of steel mesh is not just a number; it’s a critical factor that can influence various aspects of construction and engineering projects. Think about it: if you’re transporting heavy materials, the weight can add up quickly, affecting logistics and costs. So, understanding the weight of steel mesh is essential for anyone involved in construction.

Steel mesh weight varies based on its specifications. The thickness of the steel, the size of the openings, and the overall dimensions all play a role. For instance, a heavier mesh might be suitable for load-bearing applications, while lighter options could work well for non-structural uses. This variation means you need to choose wisely based on your project requirements.

To give you a clearer picture, let’s look at some typical weights for different types of steel mesh. Here’s a simple table to illustrate:

| Mesh Type | Wire Diameter (mm) | Weight (kg/m²) |

|---|---|---|

| Standard Welded Mesh | 4 | 5.0 |

| Heavy-Duty Mesh | 6 | 8.5 |

| Lightweight Mesh | 3 | 3.2 |

As you can see, the weight varies significantly depending on the type of mesh. It’s fascinating how a few millimeters can make such a difference! When planning your project, consider these weights carefully. A heavier mesh might provide better strength, but it could also increase your transportation costs.

Moreover, think about the implications of weight on your construction site. A heavier mesh can be more challenging to handle. You might need additional manpower or equipment to lift and place it. On the other hand, lighter mesh is easier to work with, but you have to ensure it meets the necessary strength requirements for your project.

In summary, the weight of steel mesh is a crucial element to consider. It affects not only the cost and logistics of your project but also its overall success. So, always take the time to evaluate the weight alongside other specifications. After all, a well-informed choice can save you time, money, and headaches down the road!

Steel Mesh Properties

When it comes to construction and engineering, the properties of steel mesh are nothing short of remarkable. This material is not just a simple grid of metal; it’s a powerhouse that enhances structural integrity. One of the standout features of steel mesh is its tensile strength. This means it can withstand significant pulling forces without breaking. Imagine trying to stretch a rubber band. Eventually, it snaps. Steel mesh, on the other hand, holds strong, making it ideal for reinforcing concrete.

Another important property is corrosion resistance. Steel mesh is often treated to resist rust and degradation. This treatment is crucial, especially in environments with high moisture or chemical exposure. Think of it as a protective shield. Without this, steel would quickly succumb to the elements, weakening structures over time. In fact, using corrosion-resistant steel mesh can extend the lifespan of a project significantly.

Flexibility is yet another key property. While steel is known for its strength, it also has a degree of flexibility that allows it to adapt to various shapes and sizes. This is particularly useful when working on complex designs. Imagine trying to fit a square peg into a round hole. With steel mesh, you can bend and shape it to meet your needs, ensuring a snug fit in any construction project.

These properties make steel mesh suitable for a wide range of applications. Here are some common uses:

- Reinforcement in concrete: Steel mesh is often used to strengthen concrete slabs, beams, and walls.

- Fencing: Its durability makes it an excellent choice for fencing solutions in both residential and commercial settings.

- Road construction: Steel mesh is utilized in roadways to provide additional support and prevent cracking.

In summary, the properties of steel mesh—its tensile strength, corrosion resistance, and flexibility—make it a vital component in modern construction. Understanding these features is essential for anyone involved in building projects. They not only enhance the durability and longevity of structures but also offer peace of mind knowing that the materials used are up to the task.

Steel Mesh Sizes

This article explores various aspects of steel mesh, including its price, weight, properties, sizes, and applications, providing a comprehensive overview for those interested in this versatile material.

When it comes to steel mesh, size really does matter. The right dimensions can make or break a project. So, what are your options? Steel mesh is available in a variety of sizes, tailored to meet different construction needs. Understanding these sizes helps ensure that you pick the perfect fit for your specific application.

Typically, steel mesh is categorized based on two main dimensions: the mesh size and the wire diameter. The mesh size refers to the number of openings per linear inch, while wire diameter indicates the thickness of the steel used. Here’s a quick breakdown:

| Mesh Size (inches) | Wire Diameter (inches) | Common Uses |

|---|---|---|

| 1/2 | 0.045 | Concrete reinforcement, flooring |

| 1 | 0.062 | Fencing, animal enclosures |

| 2 | 0.075 | Industrial applications, screens |

Choosing the right size isn’t just about aesthetics; it can affect strength and durability. For instance, a larger mesh size might be suitable for lightweight applications, while smaller sizes provide extra support in heavy-duty constructions. Think of it like choosing the right tool for a job. You wouldn’t use a hammer to screw in a bolt, right?

Another critical factor is the application. If you’re working on a construction project that requires high tensile strength, you might lean towards a smaller mesh size with a thicker wire. This combination offers better stability and support. On the other hand, if you’re looking to create a lighter structure, a larger mesh size could be ideal. It’s all about finding that sweet spot.

In summary, steel mesh comes in a range of sizes, each serving a specific purpose. Whether you’re reinforcing concrete, building fences, or creating industrial screens, knowing the right dimensions can save you time and money. So, next time you’re planning a project, take a moment to consider the size of the steel mesh you need. It could make all the difference!

Frequently Asked Questions

- What is steel mesh used for?

Steel mesh is incredibly versatile and is commonly used in construction projects. It serves various purposes, such as reinforcing concrete, providing structural support, and creating barriers. Think of it as the backbone of many structures, ensuring strength and durability.

- How does the price of steel mesh vary?

The price of steel mesh can fluctuate based on several factors, including the type of steel, mesh size, and market demand. If you’re budgeting for a project, it’s wise to keep an eye on current market trends and consult suppliers for the best deals.

- What are the different sizes of steel mesh available?

Steel mesh comes in a variety of sizes to cater to different construction needs. Standard dimensions often include 4′ x 8′, 5′ x 10′, and custom sizes can also be ordered. Choosing the right size is crucial for ensuring that it fits your specific project requirements.

- How heavy is steel mesh?

The weight of steel mesh can vary significantly depending on its gauge and dimensions. Generally, heavier mesh provides more strength, but it can also complicate transportation. It’s essential to consider both the weight and the intended use when selecting the right type.

- What properties make steel mesh suitable for construction?

Steel mesh boasts several key properties, including high tensile strength, excellent corrosion resistance, and remarkable flexibility. These attributes make it a top choice for construction, as it enhances the overall integrity and longevity of structures.