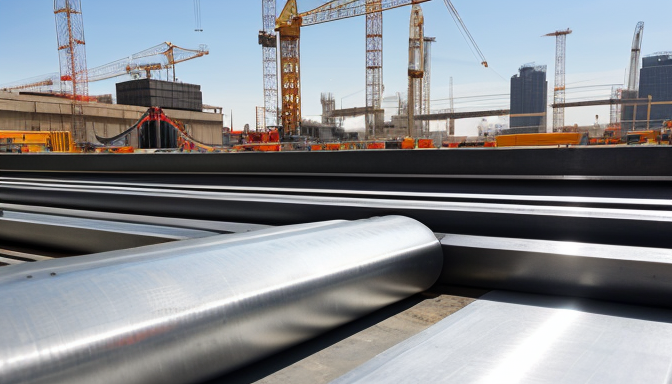

Special steel profiles are crucial components in various industries, playing a significant role in construction, manufacturing, and engineering. These profiles are not just ordinary steel; they are designed with specific properties that enhance their performance in demanding applications. Think of them as the backbone of many structures, providing strength and stability where it’s needed most. Whether you’re building a skyscraper or crafting intricate machinery, understanding special steel profiles is essential.

So, what makes these profiles special? It’s all about their unique characteristics. They are engineered to withstand extreme conditions, making them ideal for projects that require durability and reliability. From bridges to automotive parts, these profiles are everywhere, often hidden from view but critical to the overall integrity of the designs they support.

When we talk about special steel profiles, we often consider various factors such as price, weight, properties, and sizes. Each of these elements plays a vital role in determining the right profile for your project. For instance, the price can vary widely based on the type of steel used and the manufacturing process. It’s important to keep an eye on market trends to ensure you’re getting the best deal possible.

In terms of weight, it’s not just a number; it has real implications. The weight of a steel profile affects transportation costs and structural design. Heavier profiles might offer more strength but can also complicate logistics. Knowing how to calculate the weight of these profiles is essential for any project manager or engineer. It’s like packing for a trip; you want to bring everything you need without overloading your suitcase.

Now, let’s not forget about the properties that make special steel profiles so desirable. They boast impressive mechanical and physical properties, such as high tensile strength, excellent durability, and corrosion resistance. These features ensure that the profiles can endure harsh environments without compromising performance. When selecting materials, it’s crucial to consider these properties to make informed choices that will stand the test of time.

Finally, the sizes of special steel profiles can vary significantly. They come in standard dimensions but can also be customized to meet specific engineering requirements. It’s like choosing the right pair of shoes; they need to fit well to be effective. Selecting the right size is vital for ensuring that your project runs smoothly and meets all safety standards.

In conclusion, special steel profiles are more than just materials; they are essential components that contribute to the safety and efficiency of various structures and products. By understanding their price, weight, properties, and sizes, you can make better decisions that will lead to successful project outcomes.

Special Steel Profile Price

Understanding the pricing of special steel profiles is crucial for anyone involved in construction or manufacturing. Why? Because these prices can significantly impact your budget. The cost of special steel profiles varies based on several factors. For example, the type of steel used, the dimensions of the profile, and even the manufacturing process can all play a role in determining the final price.

Let’s break it down. First, consider the type of steel. Different grades have different costs. High-strength steel will typically be more expensive than standard grades. Then, there’s the size. Larger profiles require more material, which naturally increases the price. But don’t forget about the market trends. Prices can fluctuate based on supply and demand. If there’s a shortage of a particular steel type, you can expect prices to rise.

So, how can you ensure you’re getting the best value? Here are some tips:

- Research: Always compare prices from multiple suppliers.

- Bulk Orders: Buying in bulk can often lead to discounts.

- Negotiate: Don’t be afraid to negotiate prices with suppliers.

To give you a clearer picture, here’s a simple table illustrating typical price ranges for various special steel profiles:

| Profile Type | Typical Price per Ton |

|---|---|

| Standard Steel Profile | $600 – $800 |

| High-Strength Steel Profile | $900 – $1200 |

| Corrosion-Resistant Profile | $1000 – $1500 |

In conclusion, understanding the pricing of special steel profiles is more than just knowing numbers. It’s about making informed decisions that can save you money and ensure your projects are successful. Always keep an eye on the market trends and don’t hesitate to shop around. After all, a little research can go a long way in keeping your costs down.

Special Steel Profile Weight

The weight of special steel profiles is not just a number; it’s a critical factor in construction and manufacturing. Imagine trying to build a house with materials that are too heavy or too light. It just won’t work, right? The weight influences everything, from structural integrity to transportation costs. So, how do we figure out the weight of these profiles? Well, it’s all about the material’s density and the profile’s dimensions.

To calculate the weight of a special steel profile, you can use a simple formula:

Weight (kg) Volume (m³) × Density (kg/m³)

Here’s where it gets interesting. The density of steel typically ranges from 7850 kg/m³ to 8000 kg/m³. The volume depends on the profile’s size and shape. For example, a larger profile will obviously weigh more than a smaller one. But it’s not just about size. The shape matters too. A hollow profile may weigh less than a solid one of the same dimensions.

Why should you care about weight? Well, in construction, heavier materials can provide more stability, but they also increase transportation costs. If you’re shipping steel profiles across the country, every kilogram counts. On the flip side, lighter profiles can ease the load on structures but may require careful engineering to ensure safety.

Here are a few considerations when it comes to weight:

- Transport Costs: Heavier profiles cost more to ship. This can eat into your budget.

- Structural Design: Engineers must account for the weight in their calculations. Too much weight can lead to structural failure.

- Material Selection: Choosing the right profile weight can influence the overall project cost and safety.

In practical terms, let’s say you’re working on a project that requires 100 meters of a specific steel profile. If the profile weighs 10 kg per meter, you’re looking at a total weight of 1000 kg. That’s significant! You’ll need to plan for how to lift it, transport it, and support it in your design.

In the end, understanding the weight of special steel profiles is crucial. It helps you make informed decisions that can save you time and money. So, the next time you’re selecting materials for a project, remember that weight matters—more than you might think!

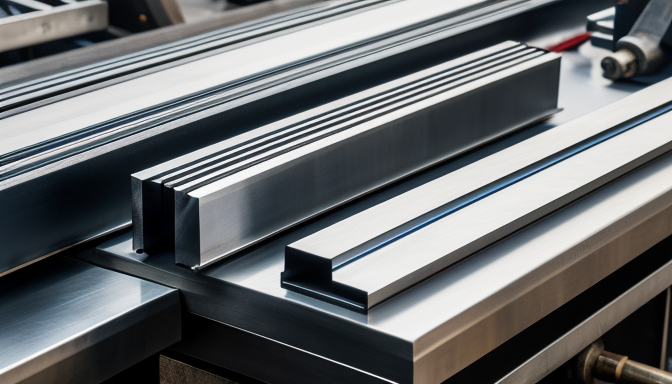

Special Steel Profile Properties

When it comes to special steel profiles, understanding their properties is key. These profiles are not just ordinary steel; they have unique characteristics that make them suitable for various applications. Think of them as the superheroes of the steel world. They possess qualities that enhance their performance, making them ideal for everything from construction to manufacturing.

One of the most important properties is strength. Special steel profiles are designed to withstand heavy loads and stresses. Imagine building a bridge. You wouldn’t want to use weak materials that could fail under pressure, right? That’s where the strength of special steel comes into play. They can handle weight and force better than standard steel, ensuring safety and durability.

Another critical property is durability. Special steel profiles are often treated or alloyed to resist wear and tear. This means they can last longer, even in harsh environments. Picture a construction site exposed to rain and wind. Regular steel might rust and weaken, but special steel profiles can stand strong against the elements. This durability is not just beneficial; it can save time and money on replacements and repairs.

Corrosion resistance is yet another vital feature. Many special steel profiles are engineered to resist rust and corrosion. This is particularly important in industries like oil and gas, where exposure to chemicals is common. If steel corrodes, it can lead to catastrophic failures. So, using corrosion-resistant profiles can be a game-changer for safety and longevity.

To give you a clearer picture, here’s a quick overview of some key properties:

| Property | Description |

|---|---|

| Strength | Ability to withstand heavy loads and stresses. |

| Durability | Resistance to wear and tear over time. |

| Corrosion Resistance | Ability to resist rust and chemical damage. |

In addition to these properties, special steel profiles can also be tailored for specific uses. This means they can be customized to meet the unique demands of different projects. Whether it’s a high-rise building or a bridge, having the right steel profile can make all the difference. So, when selecting materials, consider the properties of special steel profiles. They not only enhance performance but also ensure safety and longevity in your projects.

Special Steel Profile Sizes

When it comes to special steel profiles, size truly matters. Imagine trying to fit a square peg in a round hole. It just doesn’t work, right? The same logic applies to steel profiles in engineering and construction. The right size ensures that the materials fit perfectly into your design, providing stability and strength. But how do you determine what size you need?

First, you should know that special steel profiles come in a variety of sizes. These sizes are not one-size-fits-all. They are tailored to meet specific engineering requirements. For example, the dimensions can vary based on the application, whether it’s for a bridge, a building frame, or even machinery. Understanding these dimensions is crucial for any project.

Here’s a quick look at some common sizes and their applications:

| Profile Type | Standard Size (mm) | Typical Use |

|---|---|---|

| Square Tube | 20×20 to 300×300 | Frames, supports |

| Rectangular Tube | 40×20 to 400×200 | Beams, columns |

| I-Beam | 100×50 to 900×300 | Structural applications |

| Angle Iron | 20×20 to 150×150 | Bracing, frames |

These sizes are just the tip of the iceberg. You can also find custom sizes tailored to your specific needs. Many manufacturers offer customization options. This means you can get the exact dimensions required for your project without settling for standard sizes. Isn’t that great?

But why is selecting the right size so important? Well, choosing the wrong size can lead to structural failures, increased costs, and delays. For instance, if a profile is too small for the load it needs to bear, it can buckle under pressure. On the other hand, using an oversized profile can add unnecessary weight and cost to your project. So, it’s a balancing act!

In summary, understanding is essential for anyone involved in construction or manufacturing. Always keep in mind the specific needs of your project. Whether you go for standard sizes or opt for custom dimensions, making informed choices will lead to better outcomes. So, before you dive into your next project, take a moment to consider what size will work best!

Frequently Asked Questions

- What are special steel profiles used for?

Special steel profiles are essential in various industries, including construction, manufacturing, and automotive. They are used for structural components, frameworks, and specialized applications due to their unique properties.

- How is the price of special steel profiles determined?

The price of special steel profiles is influenced by several factors, such as material type, market demand, manufacturing processes, and customization options. It’s important to compare suppliers to find the best deals.

- What factors affect the weight of special steel profiles?

The weight of special steel profiles is determined by their dimensions, shape, and material density. Understanding weight is crucial for structural integrity and transportation logistics in any project.

- What are the key properties of special steel profiles?

Special steel profiles boast properties like high tensile strength, durability, and corrosion resistance. These characteristics make them suitable for demanding applications where performance and longevity are critical.

- Are special steel profiles available in different sizes?

Yes, special steel profiles come in a variety of sizes to meet specific engineering requirements. Many suppliers also offer customization options to ensure the profiles fit perfectly for your project needs.

- How can I calculate the weight of a special steel profile?

To calculate the weight of a special steel profile, you can use the formula: Weight Volume x Density. Knowing the dimensions and the material’s density will help you determine the weight accurately.

- What should I consider when selecting a special steel profile?

When choosing a special steel profile, consider factors like the intended application, required strength, environmental conditions, and cost. Ensuring the right profile can significantly impact the success of your project.