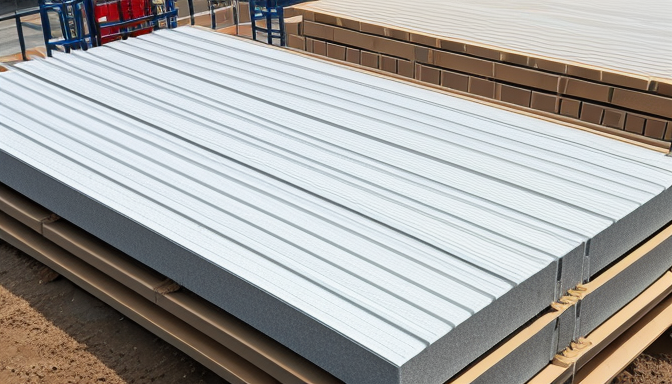

Have you ever wondered what makes a building stand strong and energy-efficient? Enter the . These panels are not just any ordinary building material; they are a combination of layers that work together to provide strength, insulation, and durability. Imagine a delicious sandwich with layers of bread, meat, and veggies. Now, think of those layers as the components of a sandwich panel. Typically, they consist of an insulating core sandwiched between two outer layers, often made of metal or other sturdy materials. This clever design is what makes sandwich panels so appealing in the construction world.

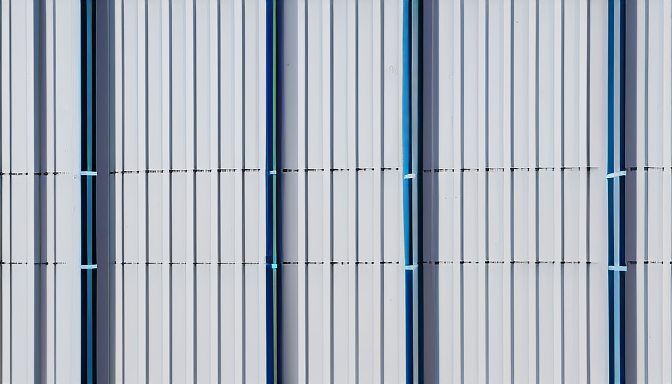

Why are they so popular? Well, their versatility shines through in various applications. From warehouses to residential homes, sandwich panels are everywhere. They offer excellent thermal insulation, which means they can keep buildings warm in winter and cool in summer. Plus, they are lightweight, making them easier to transport and install. This can save time and labor costs, which is a win-win for builders and project managers alike.

In this article, we will dive deeper into the fascinating world of sandwich panels. We’ll explore their pricing, weight, properties, sizes, and applications. Each of these aspects plays a crucial role in how sandwich panels are utilized across different industries. So, whether you are a builder, architect, or just someone curious about construction materials, there’s something here for you!

Sandwich Panel Price

When it comes to budgeting for your project, understanding the price of sandwich panels is essential. The cost can vary widely based on several factors. So, what influences these prices? Let’s break it down.

First, the material used in the sandwich panel plays a significant role. Common materials include polyurethane, polystyrene, and mineral wool. Each has its own price point, which can affect your overall budget. For instance:

| Material | Price per Square Meter |

|---|---|

| Polyurethane | $30 – $50 |

| Polystyrene | $25 – $40 |

| Mineral Wool | $35 – $60 |

Next, the thickness of the panel matters. Thicker panels often cost more, but they can provide better insulation and durability. It’s like choosing between a thin blanket and a thick one for winter. Which one keeps you warmer? Exactly!

Another factor is the size of the panels. Standard sizes are usually cheaper because they are mass-produced. Custom sizes can lead to higher costs due to the added manufacturing processes. If you need something specific, be prepared for a slight price hike.

Finally, don’t forget about shipping costs. Sandwich panels can be bulky and heavy, making transportation a significant part of the overall price. If you’re ordering from far away, those costs can stack up quickly.

In summary, the price of sandwich panels is influenced by several key factors:

- Material

- Thickness

- Size

- Shipping Costs

By keeping these factors in mind, you can better plan your budget and make informed decisions. Remember, while it might be tempting to go for the cheapest option, consider the long-term benefits of investing in quality sandwich panels. They can save you money on energy bills and maintenance in the long run. So, what’s your next step?

Sandwich Panel Weight

The weight of sandwich panels is a critical factor to consider when planning any construction project. Why? Because it affects everything from transportation to installation. A panel that is too heavy could lead to structural issues, while one that is too light might not provide the necessary support. So, let’s dive into the details.

Typically, the weight of sandwich panels varies based on their material composition. For instance, panels made from polyurethane foam tend to be lighter compared to those made with polystyrene or mineral wool. This difference can significantly influence your project’s logistics. Here’s a quick look at the average weights per square meter for various types of sandwich panels:

| Material | Weight (kg/m²) |

|---|---|

| Polyurethane | 8 – 12 |

| Polystyrene | 10 – 15 |

| Mineral Wool | 12 – 20 |

As you can see, the weight can vary quite a bit. So, why is this important? Well, the weight of the panels can affect the overall structural integrity of your project. Heavier panels might require additional support, leading to increased costs. On the flip side, lighter panels can make installation easier and quicker, saving time and labor costs.

Another aspect to consider is how the weight impacts transportation. Heavier panels can lead to higher shipping costs and may require more robust handling equipment. This is something that can sneak up on you if you’re not careful. Imagine planning everything perfectly, only to find out that your panels are too heavy for your local crane!

In conclusion, understanding the weight of sandwich panels is essential for a successful project. It influences installation, transportation, and even the type of support structures you’ll need. So, before you make any decisions, take a moment to consider how the weight of your chosen panels will play a role in your overall project plan. It might just save you time, money, and headaches down the line.

Sandwich Panel Properties

When it comes to construction materials, sandwich panels stand out for their unique properties. These panels are not just ordinary sheets; they are engineered for performance. Imagine a sandwich: two slices of bread with delicious filling in between. That’s exactly how sandwich panels work—two outer layers and a core that offers strength and insulation. Let’s dive into the key properties that make them so special.

First up is thermal insulation. This is a big deal, especially in energy-efficient buildings. The core of a sandwich panel is often made from materials like polyurethane or polystyrene which provide excellent insulation. Think about it: good insulation keeps your space warm in winter and cool in summer. It’s like having a cozy blanket wrapped around your building!

Next, let’s talk about durability. Sandwich panels are built to last. They can withstand harsh weather conditions, resist moisture, and even fend off pests. This makes them ideal for various applications, from industrial warehouses to residential homes. Imagine putting up a wall that can take a beating and still look great years down the line. That’s the promise of these panels.

Another important property is fire resistance. In today’s world, safety is paramount. Many sandwich panels come with fire-retardant properties, which means they can slow down the spread of flames. This is crucial for any building project. When you think about protecting lives and property, this feature can’t be overlooked.

Now, let’s not forget about lightweight construction. Sandwich panels are surprisingly light compared to traditional building materials. This means easier handling and installation. Imagine trying to lift a heavy brick wall versus a lightweight panel. The latter is not just easier to manage; it also reduces the load on the structure, which can save costs on foundations.

In addition to all these benefits, sandwich panels are also eco-friendly. Many manufacturers are now focusing on sustainable practices. The materials used can often be recycled, making them a more responsible choice for the environment. If you care about your carbon footprint, this is a property worth considering.

To sum it up, sandwich panels offer a combination of thermal insulation, durability, fire resistance, lightweight construction, and eco-friendliness. These properties make them a popular choice across various industries. Whether you’re building a new home, a commercial space, or an industrial facility, sandwich panels can be a smart addition to your project.

Sandwich Panel Sizes

When it comes to sandwich panels, size matters. These panels are not one-size-fits-all. They come in a variety of dimensions to suit different needs. Choosing the right size can make or break your project. So, what should you consider?

First, think about the application. Are you using sandwich panels for a warehouse, a cold storage facility, or maybe a residential building? Each application might require different sizes. For example, larger panels can speed up installation time in big warehouses. But, smaller panels might be better for intricate designs in residential homes.

Standard sizes for sandwich panels typically include:

- Width: 1,000 mm to 1,200 mm

- Length: 2,000 mm to 12,000 mm

- Thickness: 50 mm to 200 mm

These dimensions can vary based on the manufacturer and the specific material used. It’s important to consult with your supplier to get the exact sizes available. Custom sizes are also an option. If you have a unique project, many manufacturers will work with you to create panels that fit your specifications.

Now, let’s talk about the impact of size on installation and performance. Larger panels might seem like a good idea because they cover more area. However, they can be heavy and might require special equipment for installation. On the flip side, smaller panels are easier to handle but may lead to more seams. More seams can mean more potential for thermal bridging, which is something you want to avoid.

In summary, when selecting sandwich panel sizes, consider:

- The specific application and its requirements.

- The ease of installation and handling.

- Potential thermal performance based on the number of seams.

Ultimately, the right size can enhance the overall effectiveness of your project. So, take your time to evaluate your options. After all, in construction, every little detail counts!

Frequently Asked Questions

- What are sandwich panels?

Sandwich panels are composite materials made up of two outer layers and a core in between. They are designed to provide excellent insulation and structural strength, making them ideal for various applications in construction, refrigeration, and more.

- How much do sandwich panels cost?

The price of sandwich panels can vary widely based on factors such as material type, thickness, size, and manufacturer. On average, you might expect to pay anywhere from $20 to $50 per square meter, but it’s essential to get quotes from suppliers for accurate budgeting.

- What is the weight of sandwich panels?

Sandwich panels typically weigh between 10 to 30 kg per square meter, depending on the materials used. Lighter panels are easier to handle and install, while heavier ones may offer better durability and insulation. Always consider the weight when planning your project!

- What properties do sandwich panels have?

Sandwich panels are known for their outstanding thermal insulation, fire resistance, and durability. These properties make them suitable for a wide range of applications, from cold storage facilities to industrial buildings.

- What sizes do sandwich panels come in?

Sandwich panels are available in various standard sizes, typically ranging from 1 to 3 meters in width and up to 12 meters in length. Custom sizes can also be manufactured to meet specific project requirements, ensuring a perfect fit for your needs.

- Where are sandwich panels commonly used?

These panels are widely used in construction for walls, roofs, and partitions. They are also popular in the refrigeration industry for cold storage rooms and in the manufacturing of modular buildings due to their lightweight and insulating properties.