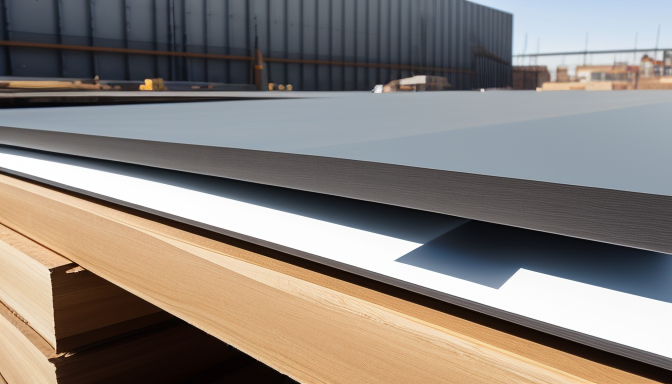

When it comes to construction and engineering, primed steel hollow section profiles are among the most versatile materials available. These profiles, often shaped like squares or rectangles, are not just about looks; they bring substantial benefits to the table. Imagine building a sturdy frame or a robust structure without worrying about the material’s strength. That’s what these profiles offer. They are designed to provide excellent support while being lightweight, making them ideal for various applications.

But what exactly makes primed steel hollow sections so special? First off, they are primed, which means they have a protective layer that helps prevent corrosion. This is a significant advantage, especially in environments where moisture is a concern. Additionally, their hollow design allows for reduced weight without sacrificing strength. Think of it like a straw; it’s lightweight and easy to handle, yet it can hold a significant amount of liquid. In the same way, these profiles can bear heavy loads while remaining easy to transport and install.

Now, let’s talk about versatility. Primed steel hollow sections are used in a variety of sectors, including construction, automotive, and even furniture design. Whether you’re framing a new building or creating a custom piece of furniture, these profiles can fit the bill. For instance, they are commonly used in:

- Structural frames for buildings

- Bridges and other infrastructure projects

- Automotive components

- Furniture manufacturing

Choosing the right profile is crucial, though. You need to consider factors like size, weight, and specific project requirements. It’s not a one-size-fits-all situation. Just like picking the right tool for a job, selecting the appropriate steel hollow section can make a world of difference. So, what are the dimensions you should keep in mind? Let’s take a closer look.

| Profile Type | Dimensions (mm) | Weight (kg/m) |

|---|---|---|

| Square Hollow Section | 50 x 50 | 3.8 |

| Rectangular Hollow Section | 100 x 50 | 6.5 |

| Square Hollow Section | 100 x 100 | 8.0 |

In summary, primed steel hollow section profiles are a fantastic choice for various projects due to their strength, lightweight nature, and resistance to corrosion. Whether you’re an engineer looking to implement them in a large-scale project or a DIY enthusiast crafting something at home, understanding their properties and applications can help you make informed decisions. Remember, the right material can enhance the durability and efficiency of your project, making it worthwhile to explore all the options available.

Primed Steel Hollow Section Profile Price

Understanding the pricing of primed steel hollow sections is crucial for anyone involved in construction or engineering projects. Prices can vary significantly based on several factors, and knowing these can help you budget more effectively. Imagine walking into a store, ready to buy your materials, but unsure of what you’ll end up spending. Frustrating, right? Let’s break it down.

First off, market demand plays a huge role in pricing. When there’s a high demand for steel, prices tend to go up. Think of it like a popular concert ticket. If everyone wants to go, the price skyrockets. Conversely, when demand dips, prices may drop. It’s a classic case of supply and demand.

Another factor is the quality of the material. Not all steel is created equal. Higher quality steel, which may be more resistant to corrosion or better suited for structural applications, will generally cost more. It’s like choosing between a standard bike and a high-end racing bike. The latter offers better performance but comes with a higher price tag.

Regional variations also affect pricing. Depending on where you are, the cost can fluctuate. For instance, in urban areas where construction is booming, you might find prices on the higher side. On the other hand, in rural areas, prices might be lower due to less demand. It’s essential to consider where you’re sourcing your materials from.

| Factor | Impact on Price |

|---|---|

| Market Demand | Higher demand higher prices |

| Material Quality | Higher quality higher prices |

| Regional Variations | Urban areas may have higher prices |

When budgeting for your project, it’s wise to get quotes from multiple suppliers. This way, you can compare prices and make informed decisions. Don’t hesitate to ask about discounts for bulk purchases too. Often, suppliers offer better rates when you’re buying larger quantities.

In conclusion, understanding the price of primed steel hollow sections is not just about knowing the numbers. It’s about grasping the factors that influence those numbers. By keeping an eye on market demand, material quality, and regional variations, you can ensure that your project stays within budget while still getting the materials you need. So, the next time you’re out shopping for steel, you’ll be ready to make smart choices.

Primed Steel Hollow Section Profile Weight

The weight of primed steel hollow sections is a key factor in construction and engineering projects. Why is this important? Well, the weight affects everything from transportation costs to structural integrity. Think about it: if you’re building a large structure, every pound counts. It can influence how much load a structure can bear and how easy it is to handle during installation.

When considering the weight of these profiles, several factors come into play. First and foremost, the dimensions of the hollow sections are crucial. Wider and taller sections will naturally weigh more. But it’s not just about the size; the material thickness also plays a significant role. Thicker walls mean more steel, which translates to increased weight. For example, a 100mm x 100mm hollow section will weigh differently depending on whether it has a wall thickness of 3mm or 6mm.

| Dimensions (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|

| 50 x 50 | 3 | 4.0 |

| 100 x 100 | 5 | 8.0 |

| 150 x 150 | 6 | 12.0 |

As you can see from the table above, the weight can vary significantly based on both dimensions and wall thickness. This variation can impact your project in several ways:

- Transportation Costs: Heavier sections may require more robust transport solutions, increasing your budget.

- Installation: Heavier materials can be more challenging to handle, potentially requiring more labor or equipment.

- Structural Design: Understanding the weight helps engineers design safer and more efficient structures.

In summary, when selecting primed steel hollow sections for your project, it’s essential to consider their weight alongside other factors. This consideration ensures you make informed decisions that align with your project’s goals. After all, a well-planned project is a successful project!

Primed Steel Hollow Section Profile Properties

When you think about construction materials, strength and durability often come to mind. Primed steel hollow sections are no exception. These profiles are designed to withstand the test of time, making them an ideal choice for various applications. But what exactly makes them stand out? Let’s dive into some key properties that enhance their performance.

First off, the strength of primed steel hollow sections is impressive. They are engineered to handle heavy loads, which is crucial in construction. Imagine building a bridge or a high-rise building; you need materials that won’t buckle under pressure. The hollow design also contributes to their strength-to-weight ratio, allowing for robust structures without excessive weight.

Another key property is corrosion resistance. Primed steel hollow sections come with a protective layer that helps them resist rust and other forms of deterioration. This is especially important in environments where moisture is prevalent. Think about it: would you want your building materials to start rusting after just a few years? Of course not! The priming process helps ensure longevity, saving you money in the long run.

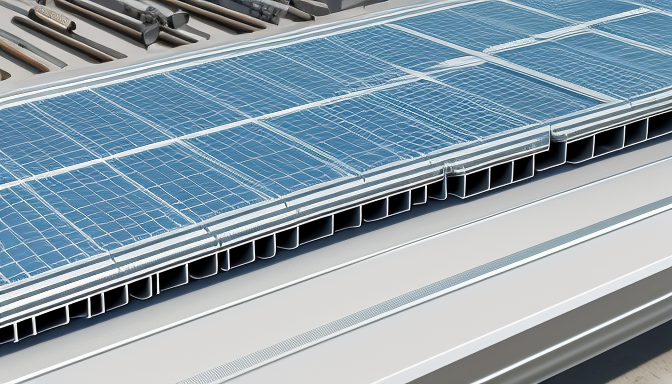

Additionally, these profiles offer versatility. They can be used in a variety of applications, from structural frameworks to decorative elements. Whether you’re working on a residential project or a large-scale commercial endeavor, primed steel hollow sections can be tailored to fit your needs. Their adaptability makes them a favorite among engineers and architects alike.

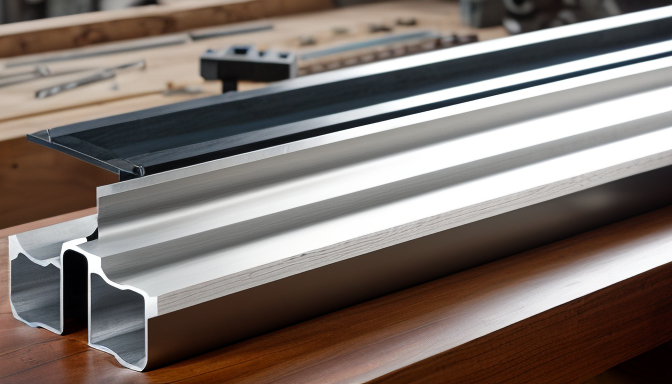

Now, let’s not forget about the ease of installation. Thanks to their uniform shape and size, these profiles are straightforward to work with. This means less time on the job site and more efficiency in your project timeline. Who doesn’t want to save time and effort? Plus, their lightweight nature makes handling and transporting them a breeze.

To summarize, here are the standout properties of primed steel hollow sections:

- Strength: High strength-to-weight ratio for heavy loads.

- Corrosion Resistance: Protective layer that enhances longevity.

- Versatility: Suitable for a wide range of applications.

- Ease of Installation: Streamlined handling and installation process.

In conclusion, when considering materials for your next project, primed steel hollow sections offer a unique combination of strength, durability, and versatility. They are a reliable choice that can adapt to various needs while ensuring long-lasting performance. So, whether you’re an engineer, architect, or DIY enthusiast, these profiles are definitely worth considering.

Primed Steel Hollow Section Profile Sizes

When it comes to primed steel hollow sections, size truly matters. Choosing the right dimensions can make or break a project. But how do you know which size is best for your needs? Let’s dive into the world of sizes and dimensions.

Primed steel hollow sections come in a variety of shapes and sizes. The most common profiles are rectangular and square. Each type serves different purposes, depending on the structural requirements of your project. For instance, if you’re building a robust framework, a larger profile might be necessary to ensure stability.

Here’s a quick breakdown of some typical sizes:

| Profile Type | Dimensions (mm) | Wall Thickness (mm) |

|---|---|---|

| Square Hollow Section | 20 x 20 to 300 x 300 | 1.5 to 12 |

| Rectangular Hollow Section | 40 x 20 to 400 x 200 | 1.5 to 12 |

These dimensions are just the tip of the iceberg. The size you choose will depend on several factors:

- Load-bearing requirements: Heavier loads require larger profiles.

- Space constraints: Sometimes, you have to work with limited space.

- Aesthetic considerations: The size can affect the overall look of your structure.

It’s also important to remember that sizes can vary by manufacturer. Always check with your supplier for the specific dimensions they offer. When selecting a size, think about the overall design of your project. Are you looking for something sleek and modern, or robust and traditional? The right profile can enhance not only the strength but also the visual appeal of your construction.

In summary, understanding the sizes of primed steel hollow sections is essential for any construction project. The right choice can lead to a solid, durable structure that meets all your needs. So, take your time, do your research, and choose wisely!

Frequently Asked Questions

- What are primed steel hollow section profiles?

Primed steel hollow section profiles are structural components made from steel that have a hollow cross-section. They are often used in construction for their strength and versatility, making them ideal for various applications such as beams, columns, and frames.

- How is the price of primed steel hollow sections determined?

The pricing of primed steel hollow sections is influenced by several factors, including market demand, the quality of the steel, and regional variations in manufacturing costs. It’s essential to compare prices from different suppliers to get the best deal.

- What factors affect the weight of primed steel hollow sections?

The weight of these profiles is primarily determined by their dimensions and material thickness. Larger sections or those with greater thickness will naturally weigh more, which is a crucial consideration for transportation and installation.

- What are the key properties of primed steel hollow sections?

Primed steel hollow sections are known for their exceptional strength, durability, and corrosion resistance. These properties make them suitable for a wide range of applications, ensuring they can withstand various environmental conditions.

- What sizes are available for primed steel hollow sections?

These profiles come in various sizes to meet different construction needs. Common dimensions include square and rectangular shapes, and selecting the right size depends on the specific requirements of your project.

- How do I choose the right size for my project?

Choosing the right size involves considering the load requirements, the space available, and the overall design of your project. Consulting with a structural engineer can help ensure you make the best choice for your needs.