Pipe laser cutting price calculation

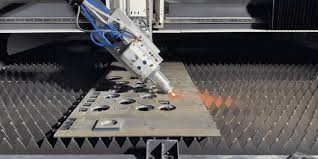

Pipe laser cutting price calculation, The cost of pipe laser cutting can vary significantly based on several factors. Here’s a breakdown of the key elements that influence the price:

Material Factors:

- Material Type: The type of material (e.g., stainless steel, carbon steel, aluminum) affects the cutting speed and energy consumption, influencing the cost.

- Material Thickness: Thicker materials generally require more laser power and cutting time, increasing the price.

- Material Grade: The grade of the material (e.g., mild steel, high-strength steel) can also impact the cutting process and cost.

Pipe Dimensions:

- Diameter: Larger diameters often require more cutting time and energy.

- Wall Thickness: Thicker walls, similar to material thickness, can increase cutting time and cost.

Cutting Complexity:

- Shape: Complex shapes with intricate details or sharp angles may require more precise cutting and programming, leading to higher costs.

- Tolerances: Tight tolerances for dimensions and angles can demand more careful cutting and inspection.

Laser Machine Specifications:

- Power: Higher laser power can increase cutting speed and efficiency, but it also comes with a higher initial investment and operating cost.

- Cutting Head: The type of cutting head (e.g., nozzle, lens) and its condition can affect cutting quality and efficiency.

Production Volume:

- Quantity: Larger quantities often lead to economies of scale, reducing the cost per unit.

- Batch Size: Processing materials in batches can optimize production efficiency and cost.

Additional Services:

- Finishing: Services like edge finishing, deburring, or surface treatment can add to the overall cost.

- Packaging: The type of packaging required can influence the handling and shipping costs.

Geographic Location:

- Labor Costs: The cost of labor in different regions can impact the overall pricing.

- Energy Costs: The cost of electricity, which is a significant factor in laser cutting, can vary geographically.

Supplier Factors:

- Experience: Suppliers with more experience and expertise may be able to offer competitive pricing and better quality.

- Equipment: The age and condition of the supplier’s laser cutting equipment can affect efficiency and cost.

- Overheads: The supplier’s overhead costs, such as rent, utilities, and administrative expenses, can contribute to the pricing.

To get a more accurate price estimate, it’s recommended to contact multiple suppliers and provide them with detailed information about your specific requirements.

Pipe Laser Cutting Quality: Key Factors

The quality of pipe laser cutting is crucial for ensuring the integrity and performance of the final product. Here are the primary factors that contribute to high-quality laser cutting:

Laser Machine Specifications:

- Power: Sufficient laser power is essential for efficient cutting and clean edges.

- Beam Quality: A high-quality laser beam with a low divergence angle ensures accurate cutting and minimal heat-affected zone (HAZ).

- Cutting Head: A well-maintained and properly adjusted cutting head is crucial for precise focusing and optimal cutting performance.

Material Factors:

- Material Properties: The physical properties of the material (e.g., thermal conductivity, reflectivity) can influence the cutting process and the quality of the cut.

- Material Condition: The surface condition of the material, including cleanliness and any defects, can affect the cutting quality.

Cutting Parameters:

- Power Density: The concentration of laser power on the material surface determines the cutting speed and quality.

- Cutting Speed: The appropriate cutting speed is essential for avoiding burn-through or undercutting.

- Gas Assist: The type and flow rate of the gas used for cutting (e.g., oxygen, nitrogen) can significantly impact the cut quality.

Process Control:

- Focus: Accurate focusing of the laser beam is critical for achieving clean cuts and minimal taper.

- Tolerance Control: Precise control of tolerances ensures that the cut parts meet the required specifications.

- Monitoring and Inspection: Regular monitoring and inspection of the cutting process help identify and address any issues before they affect the quality.

Supplier Expertise:

- Experience: A supplier with extensive experience in pipe laser cutting is more likely to have the knowledge and skills to deliver high-quality results.

- Equipment Maintenance: Proper maintenance of laser cutting equipment is essential for optimal performance and consistent quality.

- Quality Control: A rigorous quality control process ensures that the final products meet the required standards.

Additional Factors:

- Cutting Environment: Factors like temperature, humidity, and vibrations can affect the cutting process and quality.

- Material Handling: Proper handling and storage of materials can prevent damage and ensure consistent cutting results.

By carefully considering these factors, you can select a supplier that can deliver high-quality pipe laser cutting services to meet your specific needs.

Pipe laser cutting prices

| Material Type | Cutting Thickness (mm) | Average Price (USD/ton) |

|---|---|---|

| Carbon Steel | 1-3 mm | 300 |

| Carbon Steel | 3-6 mm | 350 |

| Carbon Steel | 6-10 mm | 400 |

| Stainless Steel | 1-3 mm | 350 |

| Stainless Steel | 3-6 mm | 400 |

| Stainless Steel | 6-10 mm | 450 |

| Aluminum | 1-3 mm | 350 |

| Aluminum | 3-6 mm | 400 |

| Aluminum | 6-10 mm | 450 |

| Copper | 1-3 mm | 400 |

| Copper | 3-6 mm | 450 |

Pipe laser cutting price calculation, Pipe laser cutting price, Pipe laser cutting, laser cutting, İstanbul, turkey, tube