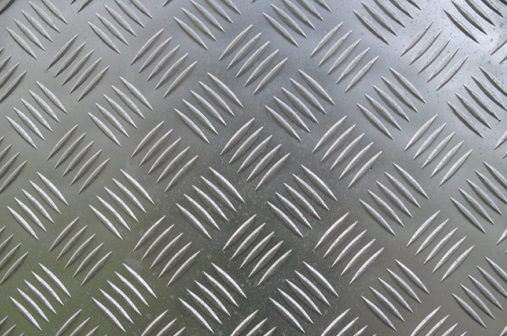

Patterned steel sheet price

When determining the price of patterned steel sheet, the complexity of the pattern is an important factor affecting the price. Intricate, deep patterns require more time and labor to produce, leading to higher costs. For instance, a geometric pattern with sharp angles might be more expensive than a simple, wavy pattern.

Material type also plays a crucial role. Stainless steel, known for its durability and corrosion resistance, is generally more expensive than carbon steel. Galvanized steel, treated with a zinc coating for protection, falls somewhere in between.

Sheet thickness and size directly impact pricing. Thicker sheets require more material and processing, while larger sheets can incur additional handling costs.

Finishes like coatings, galvanization, or special treatments can add to the price. For example, a powder-coated patterned steel sheet might be more expensive due to the extra processing steps involved.

Supplier and market conditions are dynamic and can affect prices. Economic fluctuations, changes in raw material costs, and competition among suppliers can influence the overall pricing landscape.

Location is another factor. Transportation costs, import duties, and local market demand can vary significantly between regions, impacting the price of patterned steel sheet.

Additional Considerations:

- Customization: Highly customized patterns or finishes might require specialized equipment or processes, leading to higher prices.

- Volume: Purchasing larger quantities can often result in discounts or more favorable pricing terms.

- Lead times: Urgent orders might incur rush fees or expedited shipping costs.

To obtain an accurate price:

- Contact local suppliers: They can provide customized quotes based on your specific requirements.

- Research online: Explore platforms like SteelRadar, Alibaba, Online Metals, KOÇAK ÇELİK, and Rich-Steel for potential suppliers and pricing information.

- Consider factors: Evaluate pattern complexity, material type, thickness, size, finish, supplier, market conditions, and location.

- Request samples: Obtain samples to assess quality and compare finishes before making a final decision.

By carefully considering these factors and conducting thorough research, you can make an informed decision and find the best deal for your patterned steel sheet needs.

Assessing the Quality of Patterned Steel Sheet

The quality of patterned steel sheet is a crucial factor to consider, as it directly impacts its durability, appearance, and overall performance. Here are some key aspects to evaluate:

1. Material Quality:

- Steel Grade: Ensure the steel used is of high quality and suitable for the intended application. Common grades include A36, ASTM A568, and stainless steel.

- Chemical Composition: Check the chemical composition of the steel to verify its strength, ductility, and corrosion resistance.

2. Pattern Consistency:

- Uniformity: The pattern should be consistent across the entire sheet, without any noticeable variations in depth or shape.

- Clarity: The pattern should be clear and well-defined, without any blurred or distorted lines.

3. Finish Quality:

- Surface Finish: The surface should be smooth and free from defects like scratches, pits, or scale.

- Coating Quality: If the sheet is coated (e.g., galvanized, powder-coated), the coating should be evenly applied, adhere well to the base metal, and be free from imperfections.

4. Dimensional Accuracy:

- Thickness: The sheet thickness should meet the specified tolerances to ensure proper fit and performance.

- Width and Length: The dimensions should be accurate to avoid installation problems.

5. Mechanical Properties:

- Tensile Strength: The steel should have sufficient tensile strength to withstand the expected loads.

- Yield Strength: The yield strength should be appropriate for the application to prevent excessive deformation.

- Ductility: The steel should be ductile enough to allow for bending or forming without fracturing.

6. Corrosion Resistance:

- Coating Effectiveness: If a coating is used, it should provide adequate corrosion protection in the intended environment.

- Material Properties: The base material itself should have inherent corrosion resistance, especially if it’s exposed to harsh conditions.

7. Certification and Standards:

- Compliance: Verify that the steel sheet complies with relevant industry standards and certifications (e.g., ASTM, EN, ISO).

- Quality Assurance: Check if the manufacturer has a quality assurance system in place to ensure consistent product quality.

8. Visual Inspection:

- Appearance: Examine the sheet for any obvious defects or imperfections.

- Pattern Alignment: Ensure that the pattern is properly aligned and free from distortion.

Price table

| Patterned Steel Type | Thickness (mm) | Price (USD/ton) | Availability |

|---|

| Diamond Pattern Steel Sheet | 2.0 | $800 | In Stock |

| Diamond Pattern Steel Sheet | 2.5 | $850 | In Stock |

| Tread Plate Steel Sheet | 3.0 | $880 | Limited Stock |

| Checker Plate Steel Sheet | 4.0 | $900 | In Stock |

| Embossed Steel Sheet | 5.0 | $950 | Pre-order |

| Tear Drop Pattern Steel Sheet | 6.0 | $980 | In Stock |

| Floor Plate Pattern Steel Sheet | 8.0 | $1000 | Limited Stock |