This article explores the essential aspects of Magnelis steel sheets, including their price, weight, properties, sizes, and applications, providing a comprehensive overview for potential buyers and users.

Understanding the pricing structure of Magnelis steel sheets is crucial for budgeting. Prices can fluctuate based on several factors. These include:

- Material Quality: Higher quality materials typically cost more.

- Thickness: Thicker sheets generally mean higher prices.

- Market Demand: Prices can rise or fall based on how much people want the product.

When planning a project, it’s smart to get quotes from multiple suppliers. This way, you can compare prices and find the best deal. Remember, a little research can save you a lot of money!

The weight of Magnelis steel sheets varies based on their dimensions and thickness. Knowing the weight is essential for transportation, installation, and structural calculations. For example, a thicker sheet will naturally weigh more than a thinner one. This can affect:

- Transportation Costs: Heavier sheets may cost more to ship.

- Installation Requirements: Heavier sheets might need more support during installation.

- Compliance with Specifications: Knowing the weight ensures that your project meets all necessary guidelines.

Always check the specifications before ordering. It can save you from headaches later on!

Magnelis steel sheets possess unique properties that set them apart from regular steel. They have excellent corrosion resistance and outstanding durability. These features make them suitable for various applications, especially in challenging environments. Imagine a steel sheet that can withstand harsh weather conditions without rusting. That’s the beauty of Magnelis!

Some key properties include:

- Long Lifespan: They last longer than many other materials.

- Low Maintenance: Less upkeep is needed, which saves time and money.

- Versatility: They can be used in numerous applications, from construction to automotive.

These characteristics enhance their performance and extend their lifespan, making them a smart choice for any project.

Magnelis steel sheets come in a range of sizes to meet diverse project requirements. Understanding available dimensions helps in selecting the right sheet for specific applications. For instance, if you need a sheet for roofing, the size will differ from one required for a structural beam. Here’s a quick overview of common sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 0.5 | 1000 | 2000 |

| 1.0 | 1250 | 2500 |

| 1.5 | 1500 | 3000 |

Choosing the right size ensures optimal fit and performance, which is key to a successful project.

Magnelis Steel Sheet Price

Understanding the pricing structure of Magnelis steel sheets is crucial for anyone looking to budget effectively. Prices can vary widely, and it’s important to grasp the factors that influence these costs. First off, the quality of the material plays a significant role. Higher quality sheets come with a higher price tag, but they also offer better performance and longevity. Think of it like choosing between a cheap pair of shoes and a durable, high-quality pair. One might save you money upfront, but the other will last much longer.

Another factor is the thickness of the sheet. Thicker sheets typically cost more. Why? Because they require more raw material and, often, more complex manufacturing processes. Imagine trying to build a sturdy fence; the thicker the wood, the better it can withstand the elements. Similarly, thicker Magnelis sheets provide enhanced strength and durability, making them a wise investment for many projects.

Market demand also influences pricing. When demand is high, prices tend to rise. It’s a basic principle of economics. If everyone wants Magnelis steel sheets for their projects, sellers can charge more. Conversely, during periods of low demand, prices may dip. Keeping an eye on market trends can help you snag a better deal.

To give you a clearer picture, here’s a simple table outlining typical price ranges based on thickness:

| Thickness (mm) | Price per square meter ($) |

|---|---|

| 0.5 | 3.00 – 4.00 |

| 1.0 | 5.00 – 6.50 |

| 1.5 | 7.00 – 9.00 |

| 2.0 | 10.00 – 12.00 |

When planning your budget, it’s wise to consider these factors. Not only will this help you understand the cost implications, but it will also enable you to make informed decisions. Always remember to compare prices from different suppliers. Sometimes, a small difference in price can lead to significant savings, especially for larger projects.

In conclusion, being well-informed about the pricing of Magnelis steel sheets can save you time and money. Whether you’re a contractor, a DIY enthusiast, or a business owner, understanding these costs will put you in a better position to choose the right materials for your needs.

Magnelis Steel Sheet Weight

When it comes to Magnelis steel sheets, understanding their weight is crucial. Why? Because the weight directly impacts how you handle, transport, and install these sheets. Imagine trying to lift a heavy sheet without knowing its weight first. It could lead to unexpected challenges and even safety issues. So, let’s dive into the details!

The weight of Magnelis steel sheets varies based on their dimensions and thickness. Generally, thicker sheets weigh more. For instance, a standard sheet measuring 1,000 mm by 2,000 mm with a thickness of 1.5 mm might weigh around 10 kg. However, if you were to increase the thickness to 3 mm, the weight could jump to approximately 20 kg. This increase in weight can affect your project significantly, especially when considering transportation and installation logistics.

Here’s a quick overview of how the weight changes with thickness:

| Thickness (mm) | Weight (kg) for 1m² |

|---|---|

| 1.0 | 7.85 |

| 1.5 | 11.78 |

| 2.0 | 15.70 |

| 3.0 | 23.55 |

Knowing the exact weight is not just about lifting it. It plays a crucial role in structural calculations. For example, if you’re designing a framework that will hold these sheets, you need to consider their weight for safety and stability. If the framework isn’t designed to support the weight, it could fail, leading to costly repairs and potential hazards.

Additionally, the weight affects transportation costs. Heavier sheets might require specialized vehicles or equipment for moving them. This can add to your overall project budget. So, it’s essential to factor in these details early on.

In conclusion, understanding the weight of Magnelis steel sheets is more than just a number. It’s about ensuring safety, efficiency, and cost-effectiveness in your projects. Always check the specifications and plan accordingly. After all, a well-informed decision can save you time, money, and hassle in the long run.

Magnelis Steel Sheet Properties

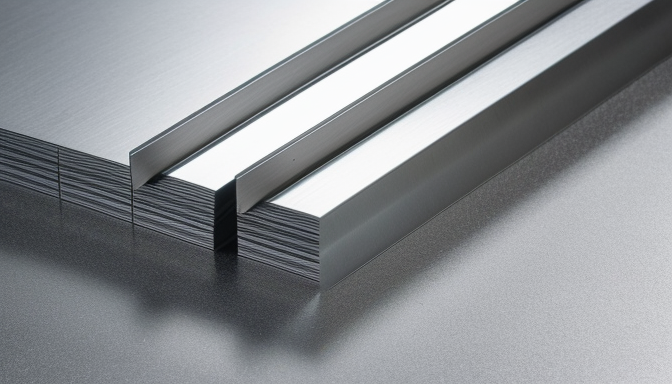

Magnelis steel sheets are not just any ordinary sheets; they are a blend of innovation and practicality. These sheets are coated with a unique layer of zinc-aluminum-magnesium alloy, which gives them exceptional corrosion resistance. Imagine having the strength of steel combined with the protective qualities of a weather-resistant coating. This makes Magnelis steel sheets perfect for outdoor applications where exposure to the elements is a concern.

One of the standout features of Magnelis steel sheets is their durability. They have a long lifespan, often outlasting traditional steel sheets in harsh environments. This durability means fewer replacements and repairs over time, which is a huge plus for both residential and commercial projects. You can think of it like investing in a sturdy umbrella that keeps you dry during a storm; it might cost a bit more upfront, but it saves you from getting soaked!

When we talk about properties, we can’t ignore the thermal performance of Magnelis steel sheets. They can withstand high temperatures, making them suitable for applications in industries like construction and manufacturing. This property ensures that they maintain their integrity even under extreme conditions. Plus, they have a low thermal expansion coefficient, meaning they won’t warp or bend easily when temperatures fluctuate.

Another significant advantage is their formability. Magnelis steel sheets can be easily cut, bent, and shaped to fit various designs and specifications. This flexibility allows architects and builders to get creative without worrying about compromising on quality. It’s like having a versatile tool in your toolbox that can adapt to any project you have in mind.

Furthermore, Magnelis steel sheets are also environmentally friendly. The production process is designed to minimize waste, and the longevity of the material reduces the need for frequent replacements. This means less material going to landfills over time. In today’s world, where sustainability is key, using Magnelis sheets can be a responsible choice.

| Property | Description |

|---|---|

| Corrosion Resistance | Outstanding protection against rust and degradation. |

| Durability | Long-lasting performance even in harsh environments. |

| Thermal Performance | Withstands high temperatures without losing integrity. |

| Formability | Easy to cut and shape for various applications. |

| Environmental Impact | Minimizes waste and promotes sustainability. |

In conclusion, the properties of Magnelis steel sheets make them a top choice for anyone looking for strength, longevity, and adaptability. Whether you’re a contractor, architect, or DIY enthusiast, understanding these properties can help you make informed decisions. So, the next time you’re considering materials for your project, remember the benefits that Magnelis steel sheets bring to the table.

Magnelis Steel Sheet Sizes

When it comes to Magnelis steel sheets, size matters. Choosing the right size is crucial for any project. It’s like picking the right tool for the job. If you get it wrong, you might find yourself in a bit of a pickle. So, let’s break down what you need to know about the sizes available.

Magnelis steel sheets are available in various dimensions to cater to different needs. Typically, these sheets range from 0.4 mm to 3 mm in thickness. The width can vary, often falling between 1,000 mm to 1,250 mm, while the length can reach up to 6,000 mm or more. But why does this matter? Well, the thickness affects the sheet’s strength and durability. Thicker sheets can withstand more stress, making them suitable for heavy-duty applications.

Here’s a quick overview of standard sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 0.4 | 1,000 | 2,000 |

| 0.5 | 1,250 | 3,000 |

| 1.0 | 1,000 | 4,000 |

| 2.0 | 1,250 | 6,000 |

| 3.0 | 1,250 | 6,000 |

But it’s not just about the numbers. Think about your project. Are you building something that needs to stand the test of time? Do you need a sheet that can handle the elements? In these cases, selecting the right size can make all the difference. If you pick a size that’s too small, you might end up with gaps or weak points. On the flip side, going too large can lead to unnecessary waste and higher costs.

Moreover, understanding the application of these sheets helps you decide on the size. For example, if you’re using Magnelis steel sheets in construction, you might need larger sizes for structural support. But for smaller applications like roofing, a thinner, smaller sheet could be just what you need.

In conclusion, knowing the sizes of Magnelis steel sheets is essential for any project. It’s about making informed decisions that lead to successful outcomes. So, before you dive into your next project, take a moment to consider the sizes available. You’ll thank yourself later!

Frequently Asked Questions

- What is Magnelis steel sheet?

Magnelis steel sheet is a type of coated steel that offers exceptional corrosion resistance and durability. It’s designed to withstand harsh environmental conditions, making it a popular choice for various applications in construction and manufacturing.

- How much does a Magnelis steel sheet cost?

The price of Magnelis steel sheets can vary widely based on factors like thickness, size, and market demand. Generally, it’s best to get quotes from suppliers to understand the current pricing structure.

- What are the typical sizes available for Magnelis steel sheets?

Magnelis steel sheets come in a variety of sizes to cater to different project needs. Standard dimensions can range from smaller sheets for specific applications to larger sheets for industrial use. Always check with suppliers for available sizes.

- How do I determine the weight of a Magnelis steel sheet?

The weight of a Magnelis steel sheet depends on its dimensions and thickness. You can calculate it using the formula: Weight Length x Width x Thickness x Density. Knowing the weight is crucial for transportation and installation planning.

- What properties make Magnelis steel sheets ideal for outdoor use?

Magnelis steel sheets are known for their superior corrosion resistance, which is achieved through a unique zinc-aluminum-magnesium coating. This makes them particularly suitable for outdoor applications where exposure to moisture and other elements is a concern.

- Can Magnelis steel sheets be used in construction?

Absolutely! Thanks to their durability and resistance to corrosion, Magnelis steel sheets are widely used in construction for roofing, wall cladding, and other structural applications. They help ensure long-lasting performance in various environments.