When it comes to steel sheets, DX54 is a term that often pops up. But what exactly is it? Simply put, DX54 steel sheets are a type of coated steel that boasts excellent formability and strength. They are primarily used in various industries due to their versatility and durability. Imagine them as the backbone of many structures and products, quietly doing their job while remaining strong and reliable.

Understanding DX54 steel sheets is essential for anyone in the manufacturing or construction sectors. Whether you’re a buyer, a project manager, or an engineer, knowing the ins and outs of these sheets can save you time and money. They come in various thicknesses and sizes, making them adaptable to different needs. Plus, their unique properties make them suitable for a wide range of applications.

So, why should you care about DX54 steel sheets? Well, consider this: the right material can make all the difference in your project. Using DX54 can enhance the structural integrity of your builds, ensuring they stand the test of time. Plus, with the right knowledge, you can optimize your costs and improve overall efficiency. It’s like choosing the right tool for a job; the right choice makes everything easier.

In the following sections, we will dive deeper into the specifics of DX54 steel sheets, including their price, weight, properties, sizes, and applications. Each aspect plays a crucial role in how these sheets perform in real-world situations. So, whether you’re looking to purchase or simply want to learn more, stick around. There’s a lot to discover!

In summary, DX54 steel sheets are more than just a product; they are a vital component in many industries. Understanding their features and benefits can empower you to make informed decisions. Let’s explore these aspects in detail and see how they can benefit you.

DX54 Steel Sheet Price

Understanding the pricing of DX54 steel sheets is essential for anyone involved in procurement or budgeting. The price of these sheets can fluctuate based on several factors. It’s not just about the material; it also involves market dynamics. Have you ever wondered why prices can change overnight? Well, it often relates to supply and demand, production costs, and even global market trends.

When considering the price of DX54 steel sheets, keep in mind the following key factors:

- Raw Material Costs: The cost of iron ore and other raw materials can significantly affect prices.

- Market Demand: High demand in industries like automotive and construction can drive prices up.

- Supplier Pricing Strategies: Different suppliers have varying pricing structures, which can impact overall costs.

- Quantity Ordered: Bulk purchases often come with discounts, making it cheaper per unit.

For example, if you’re looking to buy a small quantity for a DIY project, you might pay more per sheet compared to a large manufacturer ordering in bulk. This is crucial to remember when planning your budget. It’s like buying snacks at a convenience store versus a wholesale club—buying in larger quantities usually saves money.

To give you a clearer picture, here’s a simple table outlining a rough price range for DX54 steel sheets based on thickness:

| Thickness (mm) | Price per Sheet (USD) |

|---|---|

| 0.5 | $50 – $70 |

| 1.0 | $80 – $100 |

| 1.5 | $120 – $150 |

| 2.0 | $160 – $200 |

As you can see, the price varies significantly with thickness. This is important for buyers to consider when assessing their needs. Are you working on a lightweight project, or do you need something more robust? Knowing the price can help you make informed decisions.

In conclusion, the price of DX54 steel sheets is influenced by multiple factors. Staying informed about these variables can help you budget effectively and choose the right supplier. So, next time you’re in the market for steel sheets, remember to consider these aspects. It could save you money and ensure you get exactly what you need for your project.

DX54 Steel Sheet Weight

The weight of DX54 steel sheets is a crucial factor to consider in various projects. Why? Because it affects everything from transportation to structural integrity. When you’re planning a project, understanding the weight can help you make better decisions. It’s not just about how much it weighs; it’s about how that weight impacts your entire operation.

So, how is the weight calculated? Generally, the weight of a steel sheet is determined by its dimensions and density. The formula is simple: Weight Length × Width × Thickness × Density. The density of DX54 steel is approximately 7.85 g/cm³. This means that if you know the dimensions of your sheet, you can easily calculate its weight.

For example, let’s say you have a sheet that is 1 meter long, 1 meter wide, and 1 millimeter thick. Here’s how you would calculate the weight:

Weight 100 cm × 100 cm × 0.1 cm × 7.85 g/cm³Weight 78.5 kg

Now, let’s talk about the implications of this weight. When transporting DX54 steel sheets, knowing the weight is essential. It affects the choice of transport vehicles and the cost of shipping. A heavier load means higher fuel costs and may require special handling. Additionally, if you’re working on a construction site, understanding the weight helps in planning for proper support structures. You wouldn’t want to compromise safety, right?

Moreover, the weight of the steel sheets can influence the overall design of your project. For instance, in the automotive industry, engineers must consider weight for fuel efficiency. In construction, the weight affects the foundation and load-bearing capabilities of buildings.

In conclusion, paying attention to the weight of DX54 steel sheets is not just a detail; it’s a vital part of project planning. By understanding how to calculate it and its implications, you can ensure that your projects run smoothly and safely.

DX54 Steel Sheet Properties

When it comes to DX54 steel sheets, understanding their properties is key. These sheets are not just any ordinary steel; they are designed with specific characteristics that make them stand out in various applications. So, what makes DX54 steel sheets so special? Let’s dive into their mechanical and chemical properties.

First off, the mechanical properties of DX54 steel sheets are impressive. They offer a good balance of strength and ductility. This means they can withstand significant forces without breaking, yet they can also be shaped and formed without cracking. For instance, the yield strength and tensile strength are crucial metrics. Yield strength refers to the maximum stress that can be applied before the material begins to deform. Tensile strength, on the other hand, is the maximum stress before breaking. Here’s a quick overview:

| Property | Value |

|---|---|

| Yield Strength | ≥ 220 MPa |

| Tensile Strength | ≥ 270 MPa |

| Elongation | ≥ 28% |

But that’s not all! The chemical properties of DX54 steel sheets also play a significant role in their performance. They typically contain elements like carbon, manganese, and silicon, which enhance their durability and resistance to wear. This is particularly important in industries where the sheets are exposed to harsh environments. For instance, a steel sheet used in construction needs to resist rust and corrosion, and DX54 excels in this area.

Moreover, the surface finish of DX54 steel sheets is designed to be smooth and clean. This not only makes them visually appealing but also helps in applications where paint or coatings are applied. A good surface finish ensures better adhesion of paints, leading to longer-lasting results.

Another notable aspect is their formability. DX54 steel sheets can be easily cut, welded, and formed into different shapes. This flexibility is invaluable in manufacturing processes, allowing for the creation of complex components without compromising the integrity of the material.

In summary, the properties of DX54 steel sheets make them a popular choice across various sectors. From their mechanical strength to their chemical resilience, these sheets are designed to meet the demands of modern industry. Whether you’re in construction, automotive, or manufacturing, understanding these properties can help you make informed decisions. So, next time you consider using DX54 steel sheets, remember the unique benefits they bring to the table!

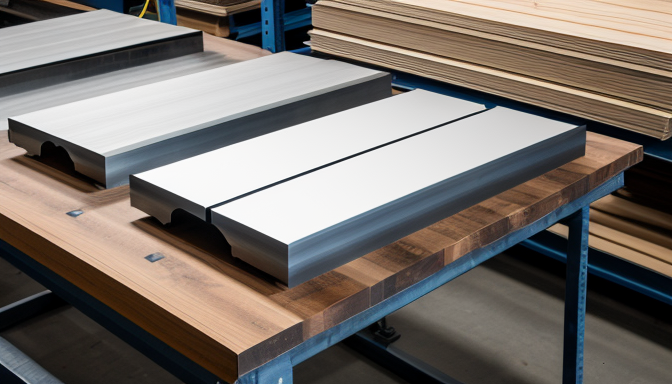

DX54 Steel Sheet Sizes

When it comes to DX54 steel sheets, size matters. The dimensions you choose can significantly impact your project. Imagine trying to fit a square peg in a round hole. Frustrating, right? That’s why understanding the available sizes is crucial for both industry professionals and DIY enthusiasts.

DX54 steel sheets come in various sizes to meet the diverse needs of different applications. Typically, these sheets can be found in standard thicknesses ranging from 0.5 mm to 3.0 mm. However, the width and length can vary widely. Common widths include 1000 mm and 1250 mm, while lengths often stretch to 2000 mm or even longer in some cases.

Choosing the right size is like picking the right tool for a job. If you’re working on a large construction project, for example, you might need wider sheets to cover more area quickly. On the other hand, smaller projects may require more manageable sizes. Understanding these dimensions helps you avoid waste and ensures that your materials fit perfectly.

Here’s a quick overview of common sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 0.5 | 1000 | 2000 |

| 1.0 | 1250 | 2500 |

| 2.0 | 1000 | 3000 |

| 3.0 | 1250 | 4000 |

When selecting a size, consider the application. For instance, in the automotive industry, smaller, thinner sheets might be preferred for body panels. In contrast, construction projects often require thicker, larger sheets for structural support. Understanding the requirements of your specific application will help guide your choice.

In summary, knowing the sizes of DX54 steel sheets is essential for making informed decisions. Whether you’re a seasoned professional or a newcomer to the field, taking the time to understand these dimensions can save you time and money. It’s all about getting the right fit for your needs!

DX54 Steel Sheet Applications

DX54 steel sheets are incredibly versatile. They find their way into numerous industries, making them a staple in modern manufacturing. But what makes these sheets so special? Let’s dive into the applications that showcase their strengths.

In the automotive industry, DX54 steel sheets are a popular choice for producing various components. Think about car frames, body panels, and even interior parts. Their strength and lightweight nature help manufacturers create vehicles that are both durable and efficient. Plus, they can be easily shaped and welded, which is a big plus in production lines.

Another significant application is in construction. From structural beams to roofing sheets, DX54 steel plays a crucial role. It provides the necessary strength to support buildings while keeping the weight manageable. This is essential for ensuring safety and stability in structures. Imagine a skyscraper swaying in the wind; it needs materials that can handle the stress without crumbling.

Moreover, DX54 steel sheets are widely used in the manufacturing sector. They serve as raw materials for various products, including appliances and machinery. The mechanical properties of these sheets allow them to withstand wear and tear, making them ideal for items that are used daily. Picture a washing machine or a refrigerator; the steel that holds them together needs to be tough and resilient.

Let’s not forget about packaging. DX54 steel sheets are utilized in creating durable containers and pallets. These materials protect goods during transport and storage. It’s amazing how something as simple as a steel sheet can keep your favorite products safe from damage.

In summary, the applications of DX54 steel sheets are vast and varied. They contribute to the automotive, construction, manufacturing, and packaging industries, among others. Their unique properties—strength, lightweight, and durability—make them an essential component in producing reliable products. Whether you’re driving a car, living in a sturdy house, or using household appliances, chances are, DX54 steel sheets are part of the story.

Frequently Asked Questions

- What is DX54 steel sheet?

DX54 steel sheet is a type of cold-rolled steel that is primarily used in various industrial applications due to its excellent formability and surface quality. It is often utilized in the manufacturing of components that require high strength and durability.

- How is the price of DX54 steel sheets determined?

The price of DX54 steel sheets can fluctuate based on several factors, including market demand, raw material costs, and supplier pricing strategies. Understanding these variables is essential for effective budgeting and procurement.

- What are the typical weights of DX54 steel sheets?

The weight of DX54 steel sheets varies depending on the thickness and dimensions. Generally, the weight can be calculated using the formula: weight volume × density, where the density of steel is approximately 7.85 g/cm³.

- What properties make DX54 steel sheets suitable for specific applications?

DX54 steel sheets possess unique mechanical properties such as high tensile strength, good ductility, and excellent weldability. These characteristics make them ideal for applications in the automotive and construction industries.

- What sizes are available for DX54 steel sheets?

DX54 steel sheets are available in a variety of sizes, including standard dimensions such as 1000mm x 2000mm and 1250mm x 2500mm. Choosing the right size is crucial for ensuring compatibility with your project requirements.

- In which industries are DX54 steel sheets commonly used?

DX54 steel sheets are commonly used in industries such as automotive, construction, and manufacturing. Their versatility and strength make them suitable for a wide range of applications, from structural components to decorative elements.