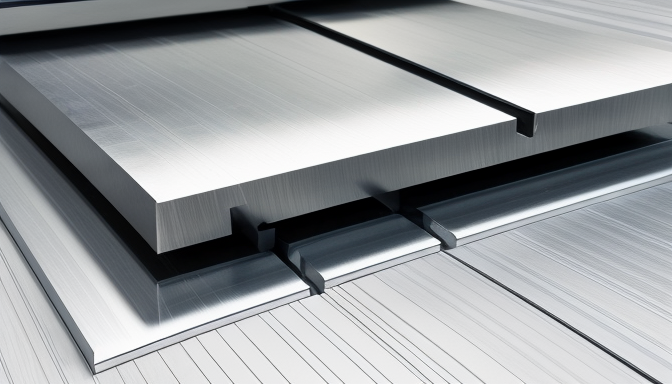

When it comes to construction and manufacturing, DX52 steel sheets are a popular choice. But what exactly is DX52 steel? In simple terms, it’s a type of cold-rolled steel that’s known for its excellent formability and strength. These sheets are often used in a variety of applications, from automotive parts to household appliances. Understanding the essentials of DX52 steel sheets can help you make informed decisions whether you are a buyer or a user.

So, why is DX52 steel so widely used? It’s all about its properties. This steel offers a good balance between strength and ductility, making it easy to work with. Plus, it can be coated for extra protection against rust and wear, which is a big plus in many industries. If you’re in the market for steel sheets, knowing the ins and outs of DX52 can save you time and money.

Now, let’s dive deeper into what makes DX52 steel sheets special. These sheets are not just any ordinary metal; they come with a set of unique properties that cater to various needs. For instance, they have a high tensile strength, which means they can withstand a lot of pressure without breaking. This is crucial in construction where safety is a priority. Additionally, they have excellent weldability, making them ideal for complex structures.

When considering DX52 steel sheets, it’s also important to think about the price. Prices can vary based on several factors such as thickness, size, and market demand. Understanding these factors can help you budget effectively. For instance, thicker sheets might cost more, but they also provide greater durability. Keeping an eye on market trends can also give you a better idea of when to buy.

In terms of sizes, DX52 steel sheets come in a variety of dimensions. This flexibility allows for customization tailored to specific projects. Whether you need large sheets for a big construction job or smaller pieces for detailed work, there’s likely a DX52 option that fits your needs. Here’s a quick overview of some common sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 0.5 | 1000 | 2000 |

| 1.0 | 1250 | 2500 |

| 2.0 | 1500 | 3000 |

In conclusion, DX52 steel sheets are a versatile and reliable choice for many industries. Their combination of strength, formability, and customization options makes them a go-to material for both manufacturers and builders. Whether you’re looking to purchase these sheets for a project or just want to understand their properties better, knowing the basics can make all the difference.

DX52 Steel Sheet Price

Understanding the price of DX52 steel sheets is crucial for anyone involved in construction or manufacturing. Why? Because the cost can significantly affect your project’s budget. Prices can fluctuate based on several factors, and it’s essential to keep an eye on these trends.

First, let’s talk about the market demand. When demand goes up, prices tend to follow suit. For instance, if a new construction boom occurs, you might find that suppliers raise prices due to the increased need for materials. On the flip side, when demand dips, prices often drop as well. It’s a simple supply-and-demand equation.

Another factor influencing the price is the quality of the steel. DX52 steel sheets come in various grades, and higher quality generally means a higher price tag. But is it worth it? Absolutely! Investing in quality materials can save you money in the long run by reducing maintenance costs and improving durability.

Additionally, geographical location plays a role in pricing. If you’re in a region where steel is scarce, expect to pay more. Conversely, areas with abundant steel production may offer more competitive pricing. Always consider your location when budgeting for materials.

To give you a clearer picture, here’s a simple table showing average prices based on thickness:

| Thickness (mm) | Average Price (per ton) |

|---|---|

| 0.5 | $600 |

| 1.0 | $580 |

| 1.5 | $550 |

| 2.0 | $530 |

Moreover, don’t forget about shipping costs. These can vary widely based on distance and weight. If you’re ordering large quantities, shipping can add a significant amount to your overall price. Always factor this into your calculations.

In summary, while the price of DX52 steel sheets can vary, being informed about market trends, quality, location, and shipping can help you make better purchasing decisions. So, keep these factors in mind as you navigate the world of steel procurement!

DX52 Steel Sheet Weight

When it comes to construction and manufacturing, understanding the weight of DX52 steel sheets is more than just a number. It can significantly affect your shipping costs and handling procedures. Imagine trying to lift a heavy load without knowing its weight. It’s a bit of a guessing game, right? Knowing how to calculate the weight of these sheets can save you from unexpected expenses and headaches.

So, how do you determine the weight of a DX52 steel sheet? It’s actually pretty straightforward. The weight can be calculated using the formula:

Weight (kg) Length (m) x Width (m) x Thickness (m) x Density (kg/m³)

For DX52 steel, the typical density is around 7850 kg/m³. Let’s break this down a little. You take the dimensions of the sheet—its length, width, and thickness—convert them into meters, and then multiply them by the density. It’s like cooking; if you have the right ingredients and measurements, you get the perfect dish!

To give you a clearer picture, let’s say you have a DX52 steel sheet that is 2 meters long, 1 meter wide, and 0.005 meters thick. Plugging these numbers into our formula:

| Dimension | Value (m) |

|---|---|

| Length | 2 |

| Width | 1 |

| Thickness | 0.005 |

Now, let’s calculate:

Weight 2 x 1 x 0.005 x 7850 78.5 kg

So, that sheet would weigh approximately 78.5 kg. Not too heavy, but definitely something to consider when planning your transport!

Weight also plays a role in how you handle these sheets. Heavier sheets may require more robust equipment for lifting and moving. Think about it: if you’re using a forklift, knowing the weight ensures you don’t overload it. Safety first, right?

In summary, understanding the weight of DX52 steel sheets is essential. It impacts not just your budget but also your operational efficiency. Always calculate before you buy, and you’ll save yourself a lot of trouble down the line!

DX52 Steel Sheet Properties

When it comes to DX52 steel sheets, understanding their properties is key to knowing why they are favored in many industries. These sheets are not just any ordinary steel; they come with a blend of characteristics that make them stand out. For starters, they are known for their excellent formability. This means they can be easily shaped and molded without breaking. Imagine trying to bend a piece of metal. If it’s too stiff, it’ll snap. But DX52? It bends like a gymnast.

Another important property is their high strength-to-weight ratio. This means you get a sturdy material without the heavy burden. Picture carrying a backpack filled with rocks versus one filled with feathers. The DX52 steel sheet gives you the strength you need while keeping things light. This property is especially beneficial in construction and automotive applications, where weight savings can lead to better fuel efficiency and lower transportation costs.

Moreover, DX52 steel sheets have good corrosion resistance. They can withstand the elements better than many other materials. This resistance is crucial for applications in environments where moisture and chemicals are prevalent. Think about it: nobody wants their materials to rust away after a few months of exposure. With DX52, you can rest easy knowing it can take a beating from the weather.

Let’s not forget about the mechanical properties that make DX52 a go-to choice:

- Tensile Strength: This refers to how much force the steel can withstand while being stretched. DX52 offers impressive tensile strength, making it suitable for demanding applications.

- Yield Strength: This is the point where the steel starts to deform permanently. DX52 maintains a good yield strength, ensuring it holds its shape under pressure.

- Elongation: This property indicates how much the steel can stretch before breaking. A higher elongation percentage means better ductility, which is a big plus for forming processes.

In summary, the properties of DX52 steel sheets make them a versatile choice for various applications. Whether you are in construction, automotive, or manufacturing, knowing these properties helps you make informed decisions. They are not just sheets of steel; they are reliable partners in your projects, ensuring durability and performance.

DX52 Steel Sheet Sizes

When it comes to DX52 steel sheets, size truly matters. The dimensions of these sheets can vary widely, and understanding the available sizes is essential for anyone involved in construction or manufacturing. Think about it: choosing the right size can make or break a project. Whether you’re working on a small DIY task or a large industrial application, having the right dimensions can save you time and money.

Typically, DX52 steel sheets come in standard sizes, but customization is also an option. Here’s a breakdown of some common dimensions:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 0.5 | 1000 | 2000 |

| 1.0 | 1250 | 2500 |

| 1.5 | 1500 | 3000 |

| 2.0 | 2000 | 4000 |

This table gives you a quick glance at some standard sizes, but remember, these are just starting points. Depending on your project’s needs, you might require something more specific. Luckily, many suppliers offer custom dimensions to fit your unique requirements. Just imagine the possibilities! You can get sheets cut to size, ensuring that you won’t waste material or time.

But why does size matter so much? Well, think of it like this: using the wrong size can lead to gaps, weak spots, or even structural failures. It’s like trying to fit a square peg in a round hole. So, before you place an order, consider the following:

- What are the exact dimensions you need?

- Will the sheets fit your machinery or tools?

- Are there specific industry standards you must adhere to?

In conclusion, understanding the sizes of DX52 steel sheets is not just about numbers; it’s about making informed decisions that can impact the success of your project. Whether you stick to standard sizes or opt for a custom solution, knowing your options is the first step toward achieving your goals. So, take your time, measure twice, and choose wisely!

Frequently Asked Questions

- What is DX52 steel sheet used for?

DX52 steel sheets are widely used in the construction and manufacturing industries due to their excellent formability and strength. They are commonly found in automotive parts, appliances, and structural components.

- How do I determine the price of DX52 steel sheets?

The price of DX52 steel sheets can vary based on factors such as thickness, size, and market demand. It’s essential to compare quotes from different suppliers and consider current market trends to get the best deal.

- What are the dimensions available for DX52 steel sheets?

DX52 steel sheets come in various standard sizes, but they can also be customized to meet specific project requirements. Common dimensions include thicknesses ranging from 0.5 mm to 3 mm, with widths and lengths tailored to client needs.

- How can I calculate the weight of a DX52 steel sheet?

To calculate the weight of a DX52 steel sheet, you can use the formula: Weight (kg) Length (m) x Width (m) x Thickness (mm) x Density (7.85 g/cm³). This will give you a good estimate of the sheet’s weight.

- What are the mechanical properties of DX52 steel?

DX52 steel sheets exhibit good tensile strength and ductility, making them ideal for applications requiring bending and shaping. They typically have a yield strength of around 220 MPa and can withstand various loads without deforming.

- Can DX52 steel sheets be painted or coated?

Yes, DX52 steel sheets can be painted or coated to enhance their corrosion resistance and aesthetic appeal. It’s recommended to use high-quality primers and paints suitable for metal surfaces to ensure durability.