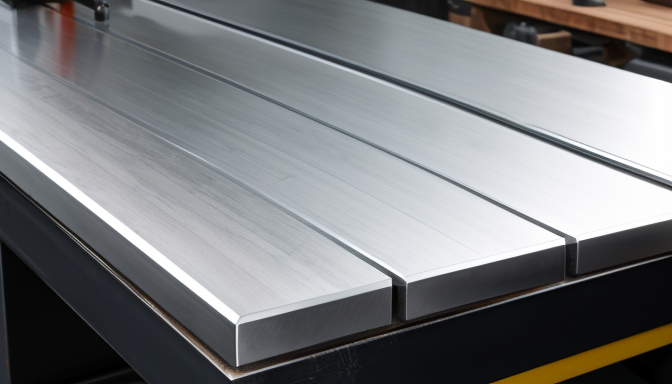

When it comes to steel sheets, DP600 stands out as a versatile choice for various industries. But what makes this material so special? Let’s dive into the key characteristics that define DP600 steel sheets and why they are gaining popularity.

First off, DP600 steel sheets are known for their excellent strength-to-weight ratio. This means you get a robust material without the extra bulk. Imagine lifting a heavy object; it’s much easier when it’s lightweight, right? That’s the essence of DP600. It’s designed to provide both durability and ease of use, making it a favorite in sectors like automotive and construction.

Another noteworthy feature is its formability. DP600 can be easily shaped and molded, which is crucial for creating complex parts. Think of it like clay; the more pliable it is, the more artistic shapes you can create. This flexibility allows manufacturers to produce intricate designs without compromising the material’s integrity.

Additionally, DP600 steel sheets offer impressive resistance to deformation. This property is particularly beneficial in high-stress environments, where traditional materials might fail. The ability to withstand such pressures means that products made from DP600 can last longer, ultimately saving costs on replacements and repairs.

Now, let’s talk about applications. DP600 steel sheets are widely used in:

- Automotive parts

- Structural components

- Heavy machinery

- Construction materials

These sheets are not just limited to one industry. Their adaptability allows them to be used in various fields, making them a go-to option for engineers and designers alike.

In summary, DP600 steel sheets are a blend of strength, formability, and durability. Whether you’re in manufacturing or construction, understanding this material can help you make informed decisions. So, if you’re considering materials for your next project, DP600 might just be the perfect fit!

DP600 Steel Sheet Price

Understanding the pricing of DP600 steel sheets is crucial for anyone involved in manufacturing or construction projects. Why? Because it directly affects your budget. The cost of these sheets can vary significantly based on several factors. For instance, the thickness, finish, and quantity you need can all play a role in determining the final price.

Currently, the market trends indicate that prices can fluctuate due to supply and demand dynamics. When demand is high, prices tend to rise. Conversely, during periods of low demand, you might find better deals. Additionally, raw material costs also impact pricing. If the price of steel increases, so will the cost of DP600 sheets.

To give you a clearer picture, here’s a rough estimate of what you can expect:

| Thickness (mm) | Approximate Price ($/ton) |

|---|---|

| 1.0 | 600 |

| 1.5 | 650 |

| 2.0 | 700 |

Keep in mind, these are just ballpark figures. Prices can vary based on your location and the supplier you choose. It’s always a good idea to get quotes from multiple sources. This way, you can compare and find the best deal.

Another factor to consider is the shipping costs. If you’re ordering large sheets, transportation can add a significant amount to your overall expenses. Make sure to factor this into your budget. Some suppliers might offer free shipping for larger orders, which can save you money.

In conclusion, while the price of DP600 steel sheets can vary, understanding the factors that influence these costs can help you make informed decisions. Always stay updated on market trends and don’t hesitate to negotiate with suppliers. After all, every penny counts when it comes to managing project budgets.

DP600 Steel Sheet Weight

The weight of DP600 steel sheets is a significant factor to consider in various applications, especially in construction and manufacturing. Why does weight matter? Well, it affects transportation costs, handling, and the overall structural integrity of the projects where these sheets are used. Understanding how to calculate the weight of DP600 steel sheets can save you time and money.

So, how do we figure out the weight? It’s pretty straightforward. The weight of a steel sheet can be calculated using the formula: Weight Length × Width × Thickness × Density. For DP600, the density is typically around 7.85 g/cm³. This means that if you know the dimensions of your steel sheet, you can easily calculate its weight.

Let’s break it down with an example. Suppose you have a DP600 steel sheet that is 2 meters long, 1 meter wide, and 0.01 meters thick. Here’s how you calculate it:

| Dimension | Value |

|---|---|

| Length (m) | 2 |

| Width (m) | 1 |

| Thickness (m) | 0.01 |

| Density (g/cm³) | 7.85 |

Now, convert the thickness to centimeters (1 m 100 cm), which gives us 1 cm. Plugging these values into the formula:

Weight 200 cm × 100 cm × 1 cm × 7.85 g/cm³ 1570000 g or 1570 kg.

That’s quite a hefty piece of material! This weight consideration is essential when planning for lifting equipment, transportation, and the overall design of the structure. If the weight is too high, it might require additional support or specialized handling equipment.

In summary, knowing the weight of DP600 steel sheets helps in making informed decisions. It’s not just about the price or the size; understanding the weight can lead to better planning and execution of your projects. After all, nobody wants to be caught off guard by unexpected costs or logistical challenges!

DP600 Steel Sheet Properties

The DP600 steel sheet is a fascinating material that stands out in the world of manufacturing and construction. Why? Because it combines strength with flexibility. Imagine a material that can withstand heavy loads while still being lightweight. That’s DP600 for you. Its unique properties make it a top choice for various applications, particularly in the automotive and structural sectors.

One of the key characteristics of DP600 steel is its excellent mechanical properties. This steel sheet has a minimum yield strength of 600 MPa, which means it can handle significant stress without deforming. In simpler terms, it’s tough! But toughness doesn’t mean it’s heavy. In fact, DP600 is designed to be lightweight, which makes it easier to transport and handle during construction.

Let’s break down some of the essential properties of DP600 steel sheets:

- Tensile Strength: This material boasts high tensile strength, which is crucial for applications that require durability.

- Formability: DP600 can be easily shaped into various forms without losing its integrity. This is vital for complex designs.

- Weldability: It can be welded without much hassle, making it a favorite among fabricators.

- Corrosion Resistance: While it’s not completely immune to rust, its resistance is decent, especially when treated.

Now, let’s talk about the chemical composition of DP600 steel. Typically, it contains a mix of iron, carbon, manganese, and other elements. This blend not only enhances its strength but also its ductility. Ductility is a fancy word for the ability to stretch without breaking. Think of it like chewing gum; it stretches but doesn’t snap. This property is essential in applications where the material needs to endure bending and twisting.

Another crucial aspect is how these properties impact performance. For instance, in the automotive industry, the lightweight nature of DP600 helps improve fuel efficiency. Cars made with this material can be lighter, which means they require less energy to move. This is a win-win for both manufacturers and consumers. Plus, the ability to withstand impacts means safety is not compromised.

In conclusion, the properties of DP600 steel sheets make them an excellent choice for a variety of applications. Their combination of strength, formability, and lightweight nature ensures they meet the demands of modern engineering. Whether you’re building a car or a structure, understanding these properties is key to making informed decisions.

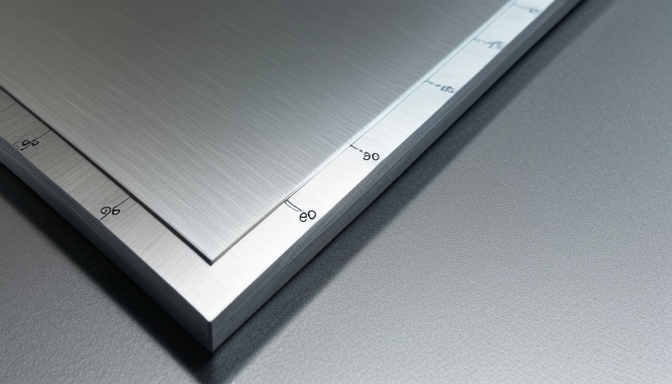

DP600 Steel Sheet Sizes

When it comes to DP600 steel sheets, size truly matters. The dimensions of these sheets can significantly influence their application in various industries. Understanding the available sizes can help you make informed decisions for your projects. Typically, manufacturers offer a range of standard sizes, but customization is often an option as well. So, what sizes should you consider?

Most commonly, DP600 steel sheets are available in the following standard dimensions:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 1.0 | 1000 | 2000 |

| 1.5 | 1250 | 2500 |

| 2.0 | 1500 | 3000 |

These sizes are just a starting point. Depending on your needs, you might require sheets that are thicker or longer. Custom sizes can be tailored to fit specific requirements, ensuring you get exactly what you need. This flexibility is one of the reasons why DP600 steel is so popular in sectors like automotive and construction.

Now, let’s talk about the importance of choosing the right size. Imagine trying to fit a square peg into a round hole. It just won’t work, right? The same principle applies when selecting your steel sheets. If the sheets are too large, you might face difficulties in handling and installation. On the other hand, sheets that are too small may not provide the structural integrity needed for your project.

In addition to standard sizes, it’s essential to consider the tolerance levels. Tolerance refers to the allowable variation in dimensions. A tight tolerance might be necessary for precision applications, while a looser tolerance could be acceptable for less critical uses. Always check with your supplier to ensure that the sheets meet your specific tolerance requirements.

In conclusion, whether you’re working on a large construction project or a smaller manufacturing task, knowing the right sizes and options for DP600 steel sheets is vital. This knowledge not only helps you stay within budget but also ensures that your project runs smoothly. So, before you place that order, take a moment to consider the dimensions you truly need. After all, the right fit makes all the difference!

Frequently Asked Questions

- What is DP600 steel sheet?

DP600 steel sheet is a dual-phase steel known for its excellent strength and formability. It’s widely used in automotive and construction applications due to its ability to withstand high stress while remaining lightweight.

- How much does DP600 steel sheet cost?

The price of DP600 steel sheets can vary significantly based on market conditions, thickness, and supplier. Generally, prices are influenced by factors such as raw material costs, manufacturing processes, and demand in the industry.

- What are the typical weights of DP600 steel sheets?

The weight of DP600 steel sheets depends on their dimensions and thickness. For example, a standard sheet measuring 1 meter by 2 meters with a thickness of 2 mm weighs approximately 4.5 kg. It’s important to calculate the weight accurately for transport and structural considerations.

- What are the mechanical properties of DP600 steel?

DP600 steel sheets exhibit high tensile strength, typically around 600 MPa, and good elongation properties. This combination allows for excellent performance in various applications, making it a preferred choice in the automotive sector.

- What sizes are available for DP600 steel sheets?

DP600 steel sheets come in various sizes, with standard dimensions often ranging from 1.2m x 2.4m to custom sizes as required by specific projects. Manufacturers can provide tailored solutions to meet unique specifications.

- What are the common applications of DP600 steel sheets?

DP600 steel sheets are primarily used in the automotive industry for components like body panels and frames, thanks to their balance of strength and weight. They’re also utilized in construction for structural elements where durability is essential.