When it comes to shipbuilding, DH36 shipbuilding steel plates are a key player. Why? Because these plates are designed specifically for the maritime industry, offering a blend of strength and durability that is hard to beat. Imagine trying to build a ship without the right materials—it’s like trying to build a house without a solid foundation. The right steel plate can make all the difference.

So, what exactly is DH36 steel? It’s a type of high-strength structural steel that meets strict standards set by the International Association of Classification Societies (IACS). This means that it’s not just any steel; it’s steel that can withstand the harsh conditions of the sea. Think of it as the superhero of shipbuilding materials. With its ability to resist corrosion and maintain structural integrity, DH36 is often the go-to choice for shipbuilders around the world.

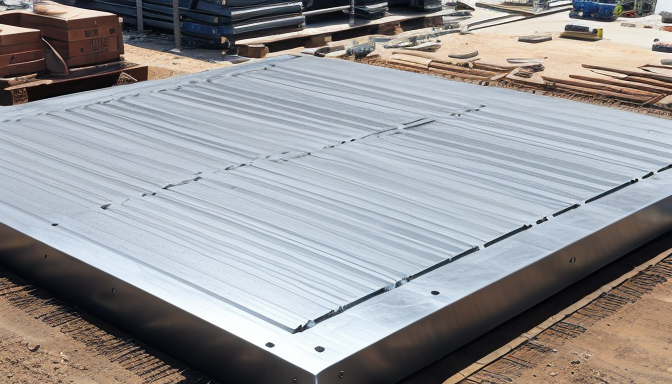

Now, let’s dive into some of the essential aspects of DH36 shipbuilding steel plates. These plates come in various sizes and thicknesses, making them versatile for different applications. Whether you’re constructing a massive cargo ship or a sleek yacht, you can find the right size to fit your needs. And the best part? They are readily available from numerous suppliers, which gives you options when it comes to sourcing.

In the maritime industry, the quality of materials is paramount. Using DH36 steel plates means you’re investing in safety. Ships built with these plates are less likely to suffer from structural failures, which can lead to costly repairs or even disasters at sea. It’s about peace of mind, knowing that your vessel is built to last.

But let’s not forget about pricing. Understanding the cost of DH36 shipbuilding steel plates is crucial for anyone involved in procurement. Prices can fluctuate based on market demand, availability, and supplier strategies. It’s wise to keep an eye on market trends and possibly negotiate with suppliers to get the best deal. After all, a good deal on materials can significantly impact your overall project budget.

In summary, DH36 shipbuilding steel plates are an essential component in the maritime industry. Their unique properties, availability in various sizes, and reliable performance make them a popular choice among shipbuilders. So, whether you’re embarking on a new project or maintaining an existing vessel, consider the advantages of using DH36 steel plates. They truly are a cornerstone of shipbuilding.

DH36 Shipbuilding Steel Plate Price

Understanding the pricing factors of DH36 shipbuilding steel plates is crucial for anyone involved in procurement. Prices can fluctuate based on several elements, and being aware of these can save you a significant amount of money. For instance, the demand in the maritime industry can impact prices. When shipbuilding projects surge, so do the prices of materials like DH36 steel. It’s like trying to buy concert tickets; when everyone wants them, the prices go up!

Another factor to consider is the supplier’s pricing strategies. Different suppliers may offer varying prices based on their own costs, relationships with manufacturers, and market positioning. It’s essential to shop around and compare quotes. Don’t just settle for the first price you see; instead, gather multiple quotes and see where you can get the best deal. You might be surprised at how much prices can differ.

In addition to market demand and supplier strategies, the quality of the steel plate also plays a vital role in determining its price. Higher quality often comes with a higher price tag, but it can be worth it in the long run. After all, you wouldn’t want to skimp on materials that ensure the safety and longevity of a ship, right?

To give you a clearer picture, here’s a simple table showing average price ranges based on thickness:

| Thickness (mm) | Average Price ($/ton) |

|---|---|

| 6 | 600 |

| 8 | 650 |

| 10 | 700 |

| 12 | 750 |

As you can see, prices can vary significantly based on the thickness of the plate. It’s important to consider what thickness is necessary for your project. Sometimes, a slightly thicker plate can provide better durability, which might save you costs on repairs later.

Finally, keep an eye on market trends. Prices can be affected by global events, such as changes in trade policies or economic conditions. Staying informed can give you a competitive edge. It’s like checking the weather before planning a picnic; you want to know what to expect!

In conclusion, understanding the price of DH36 shipbuilding steel plates requires a bit of research and awareness of the market. By keeping these factors in mind, you can make informed decisions and potentially save money on your next shipbuilding project.

DH36 Shipbuilding Steel Plate Weight

The weight of DH36 shipbuilding steel plates is a crucial factor in both design and construction. Why? Because the weight directly affects the structural integrity and overall stability of the vessels being built. Imagine trying to balance a seesaw; if one side is too heavy, it just won’t work. Similarly, in shipbuilding, every ounce counts.

Typically, the weight of DH36 plates can vary based on their thickness and dimensions. For instance, a thicker plate will naturally weigh more than a thinner one. But how do you calculate this weight? The formula is quite simple: weight volume x density. The density of DH36 steel is about 7.85 g/cm³. This means that for a plate measuring 1 meter by 1 meter and 10 mm thick, the calculation would look like this:

| Dimension (m) | Thickness (mm) | Weight (kg) |

|---|---|---|

| 1 x 1 | 10 | 78.5 |

| 1 x 1 | 20 | 157.0 |

| 1 x 1 | 30 | 235.5 |

As you can see from the table above, the weight increases significantly with thickness. This is essential for shipbuilders to consider when designing the hull and other structures of a ship. Too much weight can lead to issues like reduced speed or increased fuel consumption. On the flip side, too little weight can compromise the stability of the vessel.

Moreover, understanding the weight distribution across the ship is just as important. If the weight is unevenly distributed, it can lead to instability and even capsizing in rough waters. Picture a boat loaded with cargo; if all the heavy items are on one side, it will tip over. Thus, shipbuilders must ensure that plates are positioned correctly to maintain balance.

To summarize, the weight of DH36 shipbuilding steel plates is not just a number; it plays a vital role in the safety and efficiency of maritime vessels. By carefully considering the weight and how it fits into the overall design, shipbuilders can create robust, reliable ships ready to navigate the open seas.

DH36 Shipbuilding Steel Plate Properties

When it comes to shipbuilding, the materials you choose can make or break your project. DH36 shipbuilding steel plates are among the most popular choices. Why? Because they possess a unique blend of properties that make them ideal for maritime applications. Let’s dive into what makes these plates stand out.

First off, let’s talk about tensile strength. This is a fancy way of saying how much force a material can withstand before it breaks. DH36 plates boast a tensile strength of approximately 490 to 620 MPa. Imagine trying to pull apart a thick rubber band. The stronger the band, the more tension it can handle. Similarly, DH36 plates can endure the harsh stresses of the sea without compromising structural integrity.

Next on the list is corrosion resistance. Ships face relentless exposure to saltwater, which can eat away at metals over time. DH36 steel plates are designed to resist this corrosion, ensuring longevity and durability. It’s like wearing a raincoat in a storm. You want something that keeps you dry, and DH36 plates do just that for ships.

Another key property is ductility. This refers to how easily a material can be shaped without breaking. DH36 plates are known for their excellent ductility, allowing them to be welded and formed into various shapes. Picture a sculptor molding clay. The more flexible the clay, the better the sculpture. In shipbuilding, this flexibility allows for intricate designs and strong joints.

Now, let’s not forget about impact toughness. Ships often face rough seas, and the materials used must withstand sudden impacts. DH36 plates are tested for impact toughness, ensuring they can handle the unexpected. Think of it like a boxer who can take a punch. The tougher the fighter, the better they can withstand blows.

To sum it all up, here’s a quick look at the standout properties of DH36 shipbuilding steel plates:

- Tensile Strength: 490 to 620 MPa

- Corrosion Resistance: High resistance to saltwater

- Ductility: Excellent for shaping and welding

- Impact Toughness: Designed to withstand sudden impacts

In conclusion, the properties of DH36 shipbuilding steel plates make them a top choice for any maritime project. They offer a winning combination of strength, flexibility, and durability, ensuring that ships built with these plates can brave the toughest conditions at sea. So, when considering materials for your next shipbuilding venture, remember the unmatched qualities of DH36 steel plates!

DH36 Shipbuilding Steel Plate Sizes

When it comes to DH36 shipbuilding steel plates, size matters. The dimensions of these plates are critical in ensuring that they fit perfectly into the designs of various vessels. Why is this important? Well, the right size not only influences the construction process but also affects the overall stability and performance of the ship.

DH36 plates are available in a range of sizes, which can vary based on supplier and specific project requirements. Typically, these plates come in thicknesses ranging from 6 mm to 100 mm. Standard widths can be found in increments of 1 meter, while lengths can extend up to 12 meters or more. This flexibility allows shipbuilders to select the ideal dimensions for their unique needs.

Here’s a quick overview of some common sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 6 | 1000 | 3000 |

| 10 | 1250 | 6000 |

| 20 | 1500 | 12000 |

| 40 | 2000 | 12000 |

Choosing the right size is not just a matter of preference. It’s about ensuring that the plates can withstand the harsh conditions of the sea. For example, a ship designed for deep-sea fishing may require thicker plates to handle heavy loads and rough waters. On the other hand, smaller vessels might opt for thinner plates, which can reduce weight and enhance speed.

It’s also important to consider how the sizes of DH36 plates affect the overall design of the ship. If the plates are too large, they can be cumbersome to handle. If they’re too small, it may lead to weak joints or structural failures. Therefore, understanding the dimensions available and how they fit into your project is crucial.

In conclusion, when selecting DH36 shipbuilding steel plates, pay close attention to the sizes. They play a vital role in the construction process and the ship’s performance at sea. Always consult with your supplier to ensure you get the right dimensions for your specific needs.

Frequently Asked Questions

- What is DH36 shipbuilding steel plate?

DH36 shipbuilding steel plate is a high-strength structural steel designed specifically for shipbuilding and marine applications. Its unique properties, such as excellent weldability and corrosion resistance, make it ideal for constructing durable vessels.

- How much does DH36 shipbuilding steel plate cost?

The price of DH36 shipbuilding steel plates can vary based on market trends, supplier pricing strategies, and the quantity purchased. It’s essential to compare quotes from different suppliers to secure the best deal without compromising on quality.

- What are the weight specifications for DH36 steel plates?

Weight specifications for DH36 shipbuilding steel plates depend on their thickness and dimensions. Typically, these plates are available in various sizes, and understanding their weight is crucial for ensuring structural integrity and stability in ship design.

- What properties make DH36 steel suitable for shipbuilding?

DH36 steel plates are known for their high tensile strength, excellent toughness, and superior corrosion resistance. These properties ensure that ships built with DH36 can withstand harsh marine environments and heavy loads.

- What sizes are available for DH36 shipbuilding steel plates?

DH36 shipbuilding steel plates come in a range of standard sizes, but custom dimensions can also be ordered based on specific project requirements. It’s important to choose the right size to meet the design specifications of your vessel.

- Can DH36 steel plates be welded?

Yes, DH36 steel plates have excellent weldability, making them suitable for various welding processes. Proper welding techniques are essential to maintain the integrity and performance of the final structure.

- Where can I buy DH36 shipbuilding steel plates?

You can purchase DH36 shipbuilding steel plates from specialized steel suppliers, manufacturers, or distributors. It’s advisable to choose a reputable supplier that offers quality assurance and competitive pricing.