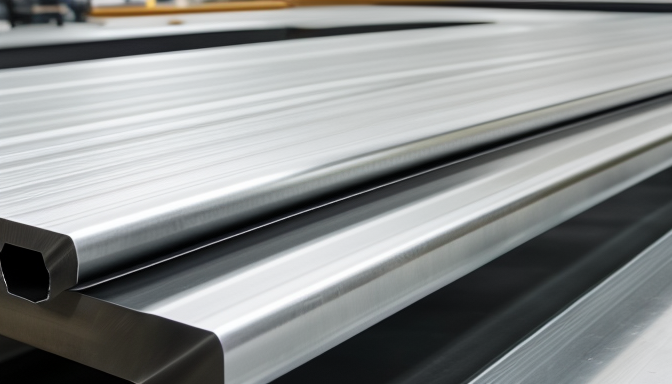

Cold rolled steel sheets are an essential material in various industries, from automotive to construction. But what exactly makes these sheets so special? To put it simply, cold rolling is a process that enhances the strength and finish of the steel. Imagine shaping a piece of dough; the more you roll it, the smoother and more uniform it becomes. Similarly, cold rolled steel sheets are refined to provide a superior surface finish and tighter tolerances compared to hot rolled steel.

But let’s dive a bit deeper. Cold rolled steel sheets are known for their high strength and durability. They are less likely to warp or distort, making them perfect for applications where precision is key. Additionally, they exhibit excellent corrosion resistance, which is crucial for products exposed to harsh environments. Think of it as a protective shield that helps maintain the integrity of the material over time.

In terms of applications, cold rolled steel sheets are incredibly versatile. They can be found in:

- Automotive parts

- Home appliances

- Furniture

- Construction materials

Each of these applications benefits from the unique properties of cold rolled steel. For instance, in automotive manufacturing, the strength and lightweight nature of these sheets contribute to fuel efficiency and safety. In construction, their durability ensures that structures can withstand the test of time.

Now, let’s talk about the pricing. The cost of cold rolled steel sheets can vary significantly based on several factors, including market demand, thickness, and surface finish. It’s essential for manufacturers to keep an eye on current trends to budget effectively. For example, during certain economic conditions, prices may surge due to increased demand in the construction sector.

When it comes to weight, cold rolled steel sheets can be surprisingly lightweight yet strong. This characteristic not only facilitates easier handling but also reduces transportation costs. Understanding the weight specifications is vital for logistics. Imagine trying to move a heavy load; the lighter the material, the easier it is to transport. Here’s a quick table to illustrate the weight of common sizes:

| Thickness (mm) | Weight (kg/m²) |

|---|---|

| 0.5 | 3.92 |

| 1.0 | 7.85 |

| 2.0 | 15.7 |

Finally, let’s discuss the sizes. Cold rolled steel sheets are available in various dimensions, which can impact their usability. Standard sizes are often readily available, but custom sizes can be ordered depending on specific project needs. This flexibility allows manufacturers to tailor their materials to fit unique applications.

In conclusion, cold rolled steel sheets are more than just a material; they are a vital component that shapes our world. Whether you’re in manufacturing, construction, or any other industry, understanding their properties, pricing, weight, and sizes can help you make informed decisions. So, the next time you come across cold rolled steel, remember the strength and versatility it brings to the table.

DKP Steel Sheet Price

Understanding the pricing of DKP steel sheets is crucial for anyone involved in manufacturing or construction. The costs can vary widely based on several factors. First, let’s talk about the raw materials. The price of steel fluctuates in the market, influenced by supply and demand dynamics. When demand is high, prices tend to rise. Conversely, during times of surplus, costs may drop. This is the nature of the beast in the steel industry.

Another key factor is the production process. Cold rolling, the method used to create DKP steel sheets, requires specific machinery and skilled labor, which can add to the overall cost. Additionally, the thickness and finish of the sheets can also impact the price. Thicker sheets or those with specialized finishes typically cost more due to the additional processing required.

It’s also essential to consider shipping and handling costs. DKP steel sheets can be heavy, and transporting them can be a significant expense. Local suppliers may offer lower prices due to reduced shipping costs, while international suppliers might have lower base prices but higher shipping fees. Therefore, it’s wise to compare local and international options before making a purchase.

To give you a clearer picture, here’s a simple table that outlines some typical price ranges for DKP steel sheets based on thickness:

| Thickness (mm) | Price Range (per ton) |

|---|---|

| 0.5 | $600 – $700 |

| 1.0 | $700 – $800 |

| 1.5 | $800 – $900 |

| 2.0 | $900 – $1,000 |

As you can see, the price increases with thickness. This information can help you make informed decisions when budgeting for your projects. Always keep an eye on market trends. Prices can change rapidly, and being aware of these shifts can save you money.

In conclusion, knowing the factors that affect DKP steel sheet prices can give you a significant advantage in your planning and purchasing decisions. Whether you’re a seasoned professional or just starting, understanding these elements will help you navigate the market more effectively.

DKP Steel Sheet Weight

The weight of DKP steel sheets is an important factor in many industries. Why? Because it directly influences logistics, handling, and overall project costs. Understanding the weight specifications can save you time and money. Imagine trying to move a heavy load without knowing how much it weighs. It can be a real headache, right? Knowing the weight helps in planning transportation and storage effectively.

DKP steel sheets are typically available in various thicknesses, which affects their weight. Thicker sheets weigh more, and this can impact how they are used in different applications. For instance, a thicker sheet might be perfect for structural applications, while a thinner one could be better suited for decorative purposes. Here’s a quick breakdown of weight based on thickness:

| Thickness (mm) | Weight (kg/m²) |

|---|---|

| 0.5 | 3.92 |

| 1.0 | 7.85 |

| 1.5 | 11.78 |

| 2.0 | 15.70 |

As you can see from the table, the weight increases with the thickness of the steel sheet. This is crucial when considering the load capacity of your equipment. If you’re using cranes or forklifts, knowing the weight can help you avoid accidents.

Moreover, the weight of DKP steel sheets can affect shipping costs. Heavier sheets might lead to higher freight charges. So, it’s wise to calculate the total weight before placing an order. This way, you can budget accordingly and avoid any surprises later on.

In practical terms, let’s say you’re working on a construction project. You need to order steel sheets for a new building. Understanding the weight will help you determine how many sheets you can safely transport at once. It also helps in planning how to store them once they arrive. After all, no one wants to deal with a pile of heavy steel sheets that are difficult to manage.

In summary, the weight of DKP steel sheets is not just a number; it’s a key piece of information that can impact your entire project. Stay informed, plan ahead, and you’ll find that working with these materials becomes a lot smoother.

DKP Steel Sheet Properties

When it comes to DKP steel sheets, understanding their properties is key. These sheets are not just flat pieces of metal; they are a blend of strength, flexibility, and durability. Imagine a sturdy shield that can withstand various conditions. That’s what DKP steel sheets offer. They are made through a cold rolling process, which enhances their surface finish and mechanical properties.

One of the standout features of DKP steel sheets is their strength. They can handle heavy loads without bending or breaking. This makes them ideal for construction and manufacturing applications. Think about it: you wouldn’t want a weak material holding up your house or machinery, right? The tensile strength of these sheets is impressive, allowing them to endure stress without yielding.

Another important property is corrosion resistance. DKP steel sheets have a protective layer that helps them resist rust and other forms of corrosion. This is especially crucial in outdoor applications or environments with high humidity. It’s like putting on a raincoat before stepping out in the rain. This property ensures that the sheets maintain their integrity over time, reducing maintenance costs and prolonging their lifespan.

The flexibility of DKP steel sheets also deserves a mention. They can be easily cut, shaped, and formed into various designs. This adaptability makes them a favorite among manufacturers who need to create customized products. Whether it’s a small part for a machine or a large panel for construction, DKP steel sheets can be tailored to fit the need. It’s like having a versatile tool in your toolbox that can tackle different jobs.

In terms of surface finish, DKP sheets have a smooth and clean appearance. This is not just for aesthetics; a smooth surface can improve paint adhesion and reduce friction in applications where metal parts move against each other. Imagine trying to paint a rough surface—it’s messy and ineffective. A smooth finish makes the job easier and more efficient.

To sum it up, the properties of DKP steel sheets make them an excellent choice for a variety of applications. Here are some key characteristics:

- High Strength: Can withstand heavy loads.

- Corrosion Resistance: Protects against rust and decay.

- Flexibility: Easily shaped and customized.

- Smooth Surface Finish: Enhances appearance and functionality.

Understanding these properties can help you make informed decisions when selecting materials for your projects. Whether you’re a professional in the industry or a DIY enthusiast, knowing what DKP steel sheets can do will guide you in choosing the right materials for your needs.

DKP Steel Sheet Sizes

When it comes to DKP steel sheets, size really matters. The dimensions of these sheets can greatly influence how they are used in various applications. Whether you’re in construction, manufacturing, or any field that relies on steel, knowing the right sizes is crucial. After all, a sheet that’s too big or too small can lead to wasted materials and increased costs. So, let’s dive into the world of DKP steel sheet sizes!

DKP steel sheets are available in a range of standard sizes. These sizes typically cater to the most common needs in the industry. Understanding these dimensions can save you time and money. Here’s a quick overview of the standard sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 0.5 | 1000 | 2000 |

| 0.8 | 1250 | 2500 |

| 1.0 | 1500 | 3000 |

These sizes are just a starting point. Many suppliers also offer custom sizes to meet specific project requirements. If you have a unique application, it’s worth checking with your supplier about the possibility of ordering sheets that fit your needs perfectly.

But why does size matter so much? Think about it. If you’re working on a project that requires precise measurements, using the wrong size can lead to complications. You might end up with a sheet that doesn’t fit your machinery, or worse, it could compromise the integrity of your project. Imagine trying to fit a square peg in a round hole—frustrating, right?

In addition to standard and custom sizes, it’s also essential to consider the weight of the sheets. Heavier sheets may require additional handling equipment, while lighter sheets might be easier to work with but less durable. Always factor in both size and weight when planning your project.

So, the next time you’re in the market for DKP steel sheets, remember that size is not just a number. It’s a critical aspect that can affect your entire project. Make sure to choose wisely, and don’t hesitate to ask your supplier for guidance. After all, a little knowledge can go a long way in ensuring your project’s success!

Frequently Asked Questions

- What is a cold rolled steel sheet?

A cold rolled steel sheet is a type of steel that has been processed at room temperature, which enhances its strength and surface finish. This process involves rolling the steel into sheets at a temperature below its recrystallization point, resulting in a smoother, more precise product compared to hot rolled steel.

- What factors influence the price of DKP steel sheets?

The price of DKP steel sheets is influenced by various factors including raw material costs, manufacturing processes, market demand, and geographic location. Additionally, fluctuations in the global steel market can significantly impact pricing, making it essential to stay updated on current trends.

- How do I determine the weight of a DKP steel sheet?

The weight of a DKP steel sheet can be calculated using its dimensions and the density of steel. Generally, the formula used is Weight Length x Width x Thickness x Density. Knowing the specific density of the steel grade will provide a more accurate weight measurement.

- What are the key properties of DKP steel sheets?

DKP steel sheets are known for their excellent strength, durability, and corrosion resistance. These properties make them suitable for a wide range of applications, from automotive to construction. Their smooth surface finish also allows for better paint adhesion and aesthetic appeal.

- What sizes are available for DKP steel sheets?

DKP steel sheets come in various standard sizes, typically ranging from 1mm to 10mm in thickness and varying widths and lengths. However, custom sizes can often be requested to meet specific project requirements, providing flexibility for manufacturers and builders.

- What applications are best suited for cold rolled steel sheets?

Cold rolled steel sheets are widely used in industries such as automotive, appliance manufacturing, and construction. Their strength and surface finish make them ideal for applications that require precision and durability, such as structural components, panels, and decorative elements.