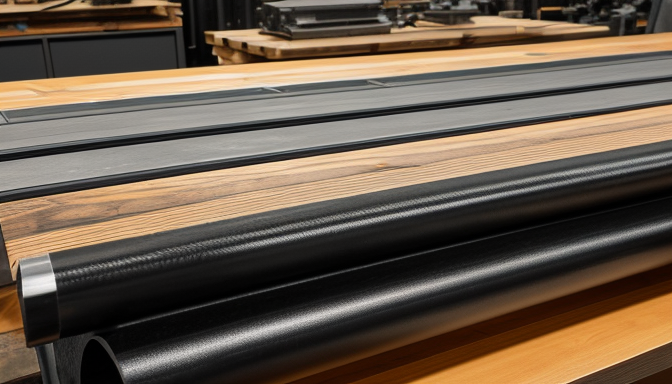

When it comes to construction and engineering, the is a crucial player. Why? Because it combines strength with versatility. Imagine building structures that not only stand tall but also withstand the test of time. That’s what black steel hollow sections bring to the table.

These profiles are typically used in various applications, from buildings to bridges. Their hollow structure allows for a lighter weight while maintaining high strength. This means less material is needed, which can save on costs without sacrificing quality. In a world where every penny counts, this is a significant advantage.

But what exactly is a black steel hollow section? In simple terms, it’s a type of steel tube that is empty inside. Think of it like a straw. It’s strong, yet light. This structure gives it unique properties that make it ideal for various uses. Whether you’re working on a residential project or a massive industrial site, these profiles can adapt to your needs.

Now, let’s dive into why these profiles are so popular. First, their durability is unmatched. Black steel can resist wear and tear, making it perfect for harsh environments. Whether exposed to moisture or extreme temperatures, it holds up well. Additionally, its corrosion resistance ensures longevity, which means fewer replacements over time.

Moreover, the cost-effectiveness of these profiles cannot be overlooked. They are generally more affordable than other materials, making them a go-to choice for builders. When budgeting for a project, choosing black steel hollow sections can lead to significant savings. Plus, they are readily available in various sizes, making them easy to source.

Speaking of sizes, these profiles come in a range of dimensions to suit different applications. Whether you need a small section for a residential fence or a larger profile for a commercial building, there’s a perfect fit out there. This flexibility is another reason why black steel hollow sections are a favorite among contractors.

In summary, black steel hollow section profiles are a fantastic choice for anyone in the construction industry. Their combination of strength, durability, and cost-effectiveness makes them an indispensable material. So, next time you’re planning a project, consider the advantages of using black steel hollow sections. They might just be the solution you need to bring your vision to life.

Black Steel Hollow Section Profile Price

Understanding the pricing of black steel hollow section profiles is crucial for anyone involved in construction or manufacturing. Why? Because knowing the cost can significantly affect your budget and project planning. Prices can vary widely based on a few key factors. For instance, the size and thickness of the profiles play a major role. Larger, thicker sections typically cost more due to the increased material used. Additionally, the market demand and availability of steel can fluctuate, impacting prices at any given time.

Current market trends also influence pricing. For example, if there’s a surge in construction projects, the demand for black steel hollow sections might spike, leading to higher prices. Conversely, during periods of low demand, prices may drop. It’s essential to stay informed about these trends to make the best purchasing decisions. A good tip is to regularly check with suppliers or industry reports to gauge the current market situation.

When looking for competitive rates, consider these strategies:

- Compare prices from multiple suppliers.

- Negotiate bulk purchase discounts.

- Keep an eye on seasonal sales or promotions.

- Establish a good relationship with your supplier for better deals.

Additionally, don’t forget about the shipping costs. Depending on where you source your materials, transportation can add a significant amount to your overall expenses. Always factor in these costs when budgeting for your project. A small savings on the material price can quickly evaporate with high shipping fees.

In summary, being aware of the factors that affect the price of black steel hollow section profiles can help you make informed decisions. It’s not just about finding the lowest price; it’s about understanding the value and ensuring that you’re getting the right product for your needs. So, keep your eyes peeled, do your research, and you’ll be well on your way to making smart purchases!

Black Steel Hollow Section Profile Weight

The weight of black steel hollow section profiles is a critical factor in construction and engineering. Why? Because it directly impacts transportation costs, structural integrity, and overall project feasibility. When you think about it, the weight of a material can be as important as its strength. If something is too heavy, it might be difficult to handle or transport. But if it’s too light, it could compromise safety. So, understanding the weight of these profiles is essential.

Black steel hollow sections come in various sizes and shapes, and their weight varies accordingly. For example, a larger profile will naturally weigh more than a smaller one. But it’s not just about size; the thickness of the walls also plays a significant role. To give you an idea, here’s a simple breakdown:

| Profile Size (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|

| 50 x 50 | 2.5 | 4.1 |

| 100 x 100 | 5.0 | 9.6 |

| 150 x 150 | 6.0 | 16.5 |

As you can see, the weight can vary significantly based on the dimensions. This table is just a snapshot, but it illustrates how different profiles can affect overall weight. When planning a project, it’s crucial to consider these weights, especially for transportation logistics. Heavy profiles might require special handling equipment, while lighter ones can be moved with standard tools.

Moreover, if you’re working on a project that requires multiple steel sections, the cumulative weight can influence your choice of materials. Think about it: if you need to transport a large quantity, even a small difference in weight can lead to significant cost variations. So, always calculate the total weight of your steel hollow sections to avoid surprises later.

In conclusion, the weight of black steel hollow section profiles is not just a number. It’s a fundamental aspect that affects your entire project. From structural integrity to transportation, every detail matters. So, when selecting your materials, take the time to understand how weight influences your choices. It could save you time, money, and a lot of headaches down the line.

Black Steel Hollow Section Profile Properties

The properties of black steel hollow section profiles play a crucial role in determining their effectiveness in various applications. These profiles are known for their strength and versatility, making them a popular choice in the construction industry. But what exactly makes them so special? Let’s dive into the key properties that set black steel hollow sections apart.

First off, let’s talk about mechanical properties. Black steel hollow sections are designed to withstand heavy loads. They exhibit excellent tensile strength, which means they can handle stretching and pulling without breaking. This is vital for structures that need to support significant weight, like bridges and high-rise buildings. Imagine a bridge swaying under the weight of traffic; the right steel profile ensures it remains stable and safe.

Another important factor is durability. Black steel is known for its resilience against wear and tear. It can endure harsh environmental conditions, including moisture and extreme temperatures. This makes it an ideal choice for outdoor structures, where exposure to the elements can be a concern. Think about it: would you want a fence that rusts away after a few rainy days? Of course not! Black steel hollow sections offer long-lasting performance.

Moreover, these profiles exhibit corrosion resistance when properly treated. While black steel itself is prone to rust, many manufacturers apply protective coatings or treatments that enhance its resistance to corrosion. This is particularly important in coastal areas where saltwater can accelerate rusting. So, if you’re considering using black steel hollow sections, look for those that come with protective measures.

In terms of weight, black steel hollow sections are relatively lightweight compared to solid steel. This characteristic makes them easier to handle and transport, reducing overall project costs. For example, a construction team can easily move these profiles on-site, saving both time and labor expenses. It’s like carrying a feather instead of a rock; the difference is significant!

Lastly, let’s not forget about the versatility of black steel hollow sections. They come in various shapes and sizes, allowing for flexibility in design and application. Whether you need square, rectangular, or circular profiles, there’s a black steel hollow section that fits your needs. This adaptability makes them suitable for a wide range of projects, from furniture manufacturing to large-scale construction.

In summary, the properties of black steel hollow section profiles—mechanical strength, durability, corrosion resistance, lightweight nature, and versatility—make them an excellent choice for many applications. When selecting materials for your next project, consider these attributes. They might just be the key to ensuring your structure stands the test of time!

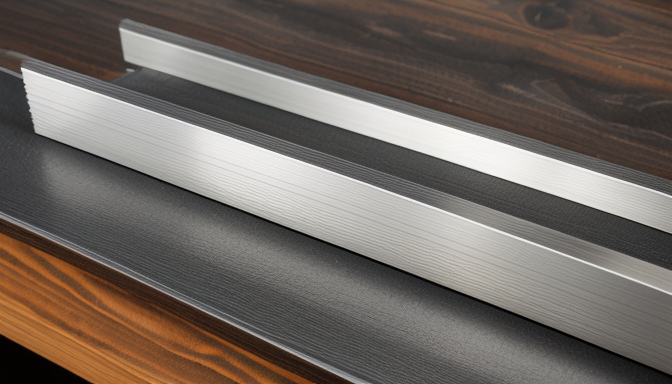

Black Steel Hollow Section Profile Sizes

When it comes to black steel hollow section profiles, size matters. The right size can make or break a project. Imagine trying to fit a square peg in a round hole; it just doesn’t work. So, understanding the available sizes is crucial for ensuring your construction needs are met. These profiles come in a variety of dimensions, catering to different applications and structural requirements.

Typically, black steel hollow sections are available in both square and rectangular shapes. The most common sizes for square hollow sections range from 20mm x 20mm to 400mm x 400mm. For rectangular profiles, you can find dimensions like 30mm x 20mm to 600mm x 400mm. These sizes are not just arbitrary; they are designed to accommodate various load-bearing requirements and design preferences.

But what if you need something specific? That’s where customization comes into play. Many suppliers offer tailored sizes to meet unique project specifications. Whether you need a specific length or a unique dimension, it’s often possible to get exactly what you need. Just remember, customized options might come with longer lead times and potentially higher costs.

Now, why is choosing the right size so important? First off, it impacts the structural integrity of your project. A profile that’s too small might buckle under pressure, while one that’s too large could lead to unnecessary weight and cost.

Here’s a quick breakdown of how to select the right size:

- Assess the load requirements: Consider what the profile will support.

- Understand the project design: Factor in aesthetic and architectural needs.

- Consult with professionals: Engineers can provide insights on the best sizes for specific applications.

In conclusion, the sizes of black steel hollow section profiles are diverse and flexible, making them suitable for a wide range of applications. Whether you’re constructing a building, creating a frame, or designing custom furniture, knowing your options is key. Always ensure to check with your suppliers for the most accurate and updated size availability. After all, the right fit can lead to a sturdy and reliable structure.

Frequently Asked Questions

- What is a black steel hollow section profile?

A black steel hollow section profile is a type of structural steel that features a hollow cross-section. These profiles are commonly used in construction due to their strength, durability, and versatility. They can come in various shapes, including square and rectangular, making them suitable for a wide range of applications.

- What factors influence the price of black steel hollow section profiles?

The price of black steel hollow section profiles can be influenced by several factors, including the size and thickness of the profile, the current market demand, and the cost of raw materials. Additionally, regional differences and the supplier’s pricing strategy can also play a role in determining the final cost.

- How do I calculate the weight of black steel hollow sections?

To calculate the weight of black steel hollow sections, you can use the formula: Weight Volume x Density. The volume can be determined by measuring the dimensions of the profile and considering the wall thickness. The density of black steel is typically around 7,850 kg/m³. This calculation helps in planning for transportation and structural requirements.

- What are the mechanical properties of black steel hollow sections?

Black steel hollow sections are known for their excellent mechanical properties, including high tensile strength, good ductility, and resistance to deformation under load. These properties make them ideal for various construction applications, ensuring they can withstand significant stress and environmental factors.

- What sizes are available for black steel hollow section profiles?

Black steel hollow section profiles are available in a wide range of sizes, from small to large dimensions. Standard sizes often include square and rectangular profiles, but many suppliers also offer customization options to meet specific project requirements. It’s essential to choose the right size based on the intended application and load-bearing needs.

- What are the common applications of black steel hollow sections?

Black steel hollow sections are widely used in various applications, including construction for structural frames, scaffolding, and support beams. They are also popular in manufacturing, automotive, and furniture industries due to their strength and aesthetic appeal. Their versatility makes them a go-to choice for engineers and architects alike.