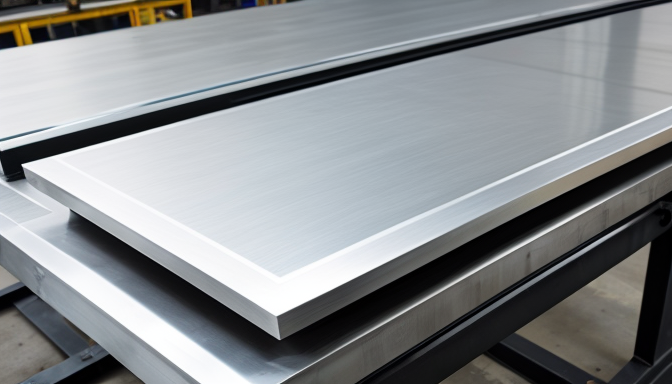

When it comes to building ships, the materials used are just as important as the design itself. One of the most crucial materials is the . This type of steel is renowned for its strength and durability, making it a go-to choice in the maritime industry. But what exactly is AH36? It’s a structural steel plate specifically designed for shipbuilding. It can withstand harsh marine environments, ensuring that vessels remain safe and reliable over time.

Now, you might be wondering why AH36 is so special. It’s all about the properties that it brings to the table. AH36 steel plates are not only strong but also have excellent weldability. This means they can be easily joined together to form the hulls of large ships. Imagine trying to build a fortress out of Lego blocks; if the blocks don’t fit well together, your fortress will crumble. Similarly, if the steel plates don’t weld well, the ship’s integrity is compromised.

In addition to strength and weldability, AH36 steel plates are also designed to handle high-stress situations. They are tested rigorously to ensure they can endure the pressures of the sea. Think of it like a superhero: they need to be tough enough to face villains, just as these plates need to withstand the harsh conditions of ocean travel.

But let’s not forget about the applications. AH36 steel plates are used in various parts of ship construction, from the hull to the decks. They provide the backbone that keeps everything together. Whether it’s a cargo ship or a luxury yacht, AH36 plates are often the unsung heroes that make these vessels possible.

In summary, AH36 shipbuilding steel plates are essential for anyone in the maritime industry. Their unique properties, such as strength, weldability, and high-stress resistance, make them a top choice for shipbuilders. Next time you see a ship, remember the importance of the materials that went into its construction. It’s not just about what you see on the surface; it’s about what’s beneath, holding everything together.

AH36 Shipbuilding Steel Plate Price

Understanding the pricing of AH36 shipbuilding steel plates is essential for anyone involved in maritime construction. Why? Because the price can vary significantly based on several factors. Think about it: if you’re building a ship, the cost of materials can make or break your budget. So, let’s dive into what drives these prices.

First off, market trends play a huge role. The demand for ships can fluctuate due to economic conditions, which directly impacts steel prices. For instance, when the maritime industry sees a boom, prices tend to rise. Conversely, during downturns, prices might drop. It’s like a roller coaster ride—up and down, all depending on market dynamics.

Next, we have the quality of the steel. AH36 is known for its durability and strength, but not all suppliers offer the same quality. If you want high-grade steel, you might pay a premium. It’s similar to buying a branded product versus a generic one; you often get what you pay for. Additionally, factors like the thickness and size of the plates can also affect the cost. Thicker plates require more material, thus increasing the price.

Another crucial aspect is the supplier’s location. Shipping costs can add up quickly, especially if you’re sourcing materials from overseas. For example, if you’re in the U.S. and ordering from a European supplier, you might face hefty shipping fees. It’s wise to consider local suppliers to cut down on those extra costs.

So, how do you find competitive pricing? Here are a few tips:

- Research multiple suppliers. Don’t settle for the first quote you receive.

- Ask for bulk discounts. If you’re ordering large quantities, many suppliers are willing to negotiate.

- Stay updated on market trends. Knowing when prices are likely to rise or fall can help you make informed purchasing decisions.

In summary, the price of AH36 shipbuilding steel plates is influenced by market trends, quality, size, and supplier location. By being informed and proactive, you can navigate the complexities of pricing and make choices that align with your project needs. Remember, in the world of shipbuilding, every dollar counts!

AH36 Shipbuilding Steel Plate Weight

The weight of AH36 shipbuilding steel plates is a crucial factor in ship design and construction. Why does this matter? Well, the weight directly influences the overall performance and efficiency of a vessel. When engineers and designers are crafting a ship, they must consider not just the steel’s strength but also how heavy it will be. Too much weight can lead to increased fuel consumption and reduced speed. So, understanding the weight specifications of AH36 plates is key.

Typically, the weight of AH36 steel plates varies based on their dimensions. For example, a standard plate measuring 1 inch thick and 4 feet by 8 feet can weigh around 500 pounds. This number can change based on the thickness and size of the plates. To make things clearer, here’s a simple table that outlines the weight of different thicknesses of AH36 steel plates:

| Thickness (inches) | Weight per square foot (lbs) |

|---|---|

| 0.25 | 20 |

| 0.50 | 40 |

| 0.75 | 60 |

| 1.00 | 80 |

As you can see, the thickness plays a significant role in determining the weight. But it’s not just about the numbers. The weight impacts how ships are built and how they perform in the water. A heavier ship may have better stability, but it might also require more powerful engines to move. This balance is a delicate dance that shipbuilders must master.

In my experience, I’ve seen projects where weight savings were crucial. For instance, during the construction of a fishing vessel, the team opted for thinner AH36 plates to reduce weight. This decision allowed for a more efficient engine and better fuel economy. It’s fascinating how a seemingly simple choice can ripple through the entire design and operational aspects of a ship.

So, when considering AH36 shipbuilding steel plates, remember that weight isn’t just a number; it’s a vital element that affects the entire vessel. Whether you’re an engineer, a buyer, or just someone interested in maritime construction, understanding the weight of these plates will help you appreciate the complexities of shipbuilding.

AH36 Shipbuilding Steel Plate Properties

When it comes to shipbuilding, the choice of materials is crucial. Among these, AH36 shipbuilding steel plates stand out for their remarkable properties. But what exactly makes them so special? Let’s dive into the key characteristics that define AH36 steel plates and their importance in marine applications.

First off, AH36 steel is known for its high strength. This property is essential for vessels that must endure harsh conditions at sea. Ships face constant pressure from waves, wind, and weight. AH36 plates provide the durability needed to withstand these forces. Imagine trying to build a sturdy house on a shaky foundation. Without strong materials, the structure would crumble. Similarly, a ship needs robust steel to maintain its integrity.

Another important property is ductility. This refers to the material’s ability to deform without breaking. Ductility is vital for shipbuilding because it allows the steel to absorb energy from impacts and stresses. Think of it like a rubber band. It stretches and bends but doesn’t snap easily. AH36 steel plates can flex under pressure, making them less likely to fail in critical situations.

Moreover, AH36 steel exhibits excellent weldability. This means it can be easily welded, which is a significant advantage during construction. In shipbuilding, various sections must be joined together securely. If the steel were difficult to weld, it would complicate the assembly process. Thanks to its weldability, AH36 steel simplifies construction, allowing for faster and more efficient shipbuilding.

In terms of corrosion resistance, AH36 plates are treated to withstand the salty, humid conditions of marine environments. Corrosion can be a ship’s worst enemy, leading to structural weaknesses over time. Using AH36 steel helps mitigate this risk, ensuring longer-lasting vessels. It’s like applying a protective coating to a car to prevent rust. The better the protection, the longer the vehicle lasts.

To sum it up, here are some key properties of AH36 shipbuilding steel plates:

- High Strength: Essential for durability under pressure.

- Ductility: Allows for deformation without breaking.

- Weldability: Facilitates easy and secure construction.

- Corrosion Resistance: Protects against harsh marine environments.

In conclusion, the properties of AH36 shipbuilding steel plates make them a go-to choice for the maritime industry. Their strength, ductility, weldability, and corrosion resistance ensure that ships can be built to last. When you think about constructing a vessel, remember the importance of choosing the right materials. AH36 steel plates not only meet the demands of shipbuilding but also enhance the overall performance and safety of marine vessels.

AH36 Shipbuilding Steel Plate Sizes

When it comes to AH36 shipbuilding steel plates, size really does matter. The dimensions of these plates can significantly affect the construction and performance of a vessel. So, what sizes are available? The good news is that AH36 plates come in a variety of standard dimensions, which makes them versatile for different maritime projects.

Typically, the thickness of AH36 plates ranges from 6 mm to 100 mm. This wide range allows shipbuilders to choose the appropriate thickness based on the specific requirements of their designs. For instance, thicker plates are ideal for parts of the ship that experience higher stress, while thinner plates can be used in less critical areas.

Standard widths often fall between 1,500 mm and 3,000 mm, while lengths can reach up to 12,000 mm. Such dimensions provide flexibility, enabling shipbuilders to optimize material usage and minimize waste. However, if a project requires custom sizes, many suppliers offer tailored solutions. This means you can get plates cut to fit your unique specifications.

It’s also essential to consider the weight of these plates when determining sizes. Heavier plates can impact the overall weight distribution of the vessel, which can affect its stability and performance in the water. Therefore, precise calculations are crucial.

To give you a clearer picture, here’s a simple table that outlines some common sizes of AH36 shipbuilding steel plates:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 6 | 1500 | 6000 |

| 10 | 2000 | 8000 |

| 20 | 2500 | 10000 |

| 40 | 3000 | 12000 |

In summary, the sizes of AH36 shipbuilding steel plates are designed to meet a wide range of maritime needs. Whether you’re constructing a small boat or a large cargo ship, understanding the available dimensions can help you make informed choices. Remember, the right size not only enhances the structural integrity of the vessel but also contributes to its overall efficiency on the water.

Frequently Asked Questions

- What is AH36 shipbuilding steel plate used for?

AH36 shipbuilding steel plates are primarily used in the construction of ships and marine structures. Their strength and durability make them ideal for building hulls, decks, and other critical components that need to withstand harsh marine environments.

- How is the price of AH36 shipbuilding steel plates determined?

The price of AH36 shipbuilding steel plates can vary based on several factors, including market demand, raw material costs, and manufacturing processes. It’s essential to keep an eye on market trends and seek quotes from multiple suppliers to find competitive pricing.

- What are the key properties of AH36 steel plates?

AH36 steel plates are known for their excellent mechanical properties, including high tensile strength and good weldability. They also exhibit resistance to corrosion, making them suitable for maritime applications where exposure to water is constant.

- What sizes are available for AH36 shipbuilding steel plates?

AH36 shipbuilding steel plates come in various sizes to accommodate different construction needs. Standard dimensions are available, but many suppliers also offer custom sizes to meet specific project requirements.

- How does the weight of AH36 steel plates affect ship design?

The weight of AH36 steel plates plays a crucial role in ship design, as it influences the overall stability and performance of the vessel. Lighter plates can enhance speed and fuel efficiency, while heavier plates may provide additional strength but can impact buoyancy.

- Can AH36 shipbuilding steel plates be recycled?

Yes, AH36 shipbuilding steel plates are recyclable. This makes them an environmentally friendly option, as they can be repurposed for new constructions or other steel products, helping to reduce waste in the industry.