This article explores A36 steel sheets, covering their price, weight, properties, sizes, and applications to provide a comprehensive understanding of this versatile material used in various industries. A36 steel is a low carbon steel that is widely used in construction and manufacturing due to its excellent weldability and machinability. It’s like the bread and butter of the steel world, simple yet effective.

When you think of A36 steel, think of a strong foundation. It’s used in buildings, bridges, and even in the making of heavy equipment. Why? Because it can withstand a lot of pressure without cracking or breaking. Whether you’re a contractor, an engineer, or a DIY enthusiast, understanding A36 steel is essential. It’s not just about knowing what it is, but also how it can fit into your projects.

In this article, we’ll dive deeper into the specifics. We’ll look at how much A36 steel sheets cost, how to calculate their weight, and what makes them so special in terms of properties. We’ll also explore the various sizes available to suit different needs. By the end, you’ll have a solid grasp of A36 steel sheets and how they can benefit your work.

A36 Steel Sheet Price

Understanding the pricing of A36 steel sheets is crucial for budgeting projects. You might be wondering, what factors actually influence the cost? Well, several elements come into play. First off, the market demand for steel can fluctuate. When demand is high, prices tend to rise. Conversely, when demand drops, prices can fall. It’s a bit like the weather; sometimes it’s sunny, and other times it rains!

Another significant factor is the thickness and size of the steel sheet. Thicker sheets require more raw material. So, naturally, they cost more. For instance, a 1/4 inch thick sheet will be priced differently than a 1/2 inch thick one. Additionally, the supplier you choose can greatly affect your final price. Some suppliers may offer discounts for bulk orders, while others might have a fixed pricing structure. Here’s a quick look at how different thicknesses can impact pricing:

| Thickness (inches) | Approximate Price per Sheet |

|---|---|

| 1/8 | $50 |

| 1/4 | $100 |

| 1/2 | $200 |

Current market trends also play a pivotal role. For example, if there’s a surge in construction projects, the demand for A36 steel can skyrocket. This can lead to higher prices. On the flip side, if a recession hits, prices might drop as projects slow down. Keeping an eye on these trends can help you plan your purchases better.

So, how can you ensure you’re getting the best price? Here are a few tips:

- Shop around. Compare prices from different suppliers.

- Consider buying in bulk. You might snag a discount.

- Stay updated on market trends. Timing can save you money!

In conclusion, understanding the price of A36 steel sheets is about more than just numbers. It’s about knowing the market, the suppliers, and how various factors come into play. This knowledge can help you make informed decisions, ensuring that your project stays within budget while still getting the quality materials you need.

A36 Steel Sheet Weight

When it comes to A36 steel sheets, understanding their weight is crucial. Why? Because the weight can significantly affect transportation and handling during your projects. Imagine trying to lift something heavy. It can be a real hassle, right? Knowing the weight helps you plan better and avoid those unexpected surprises.

To calculate the weight of an A36 steel sheet, you need to consider its dimensions and thickness. Here’s a simple formula to help you out:

Weight (lbs) Length (in) x Width (in) x Thickness (in) x 0.2836

This formula gives you the weight in pounds. It’s straightforward, but let’s break it down a bit:

- Length: The longer the sheet, the heavier it will be.

- Width: Wider sheets add more weight.

- Thickness: Thicker sheets mean more material, thus more weight.

For example, a standard A36 steel sheet that measures 4 feet by 8 feet and is 1/4 inch thick would weigh approximately:

| Length (in) | Width (in) | Thickness (in) | Weight (lbs) |

|---|---|---|---|

| 48 | 96 | 0.25 | 240 |

So, there you have it! That sheet would weigh around 240 pounds. Knowing this helps when you’re planning for transportation. You want to make sure your truck can handle it, right?

Also, consider the impact of weight on your project. Heavier sheets may require more robust equipment for lifting and installing. Always think ahead. Are you working alone? Or do you have a team? These factors can influence how you manage the weight during installation.

In conclusion, understanding the weight of A36 steel sheets is not just a number. It’s a key part of project planning. Knowing how to calculate it, and considering the implications, can save you time and trouble down the road.

A36 Steel Sheet Properties

A36 steel is a popular choice in the construction and manufacturing industries. Why? Because it boasts a mix of strength and weldability that makes it incredibly versatile. Let’s dive deeper into what makes A36 steel sheets stand out.

First off, let’s talk about the mechanical properties. A36 steel has a yield strength of around 36,000 psi. This means it can withstand a fair amount of stress before deforming. Imagine trying to bend a thick piece of cardboard. It will bend, but if you apply just the right amount of pressure, it will snap. A36 steel, on the other hand, can handle much more before reaching its breaking point.

Next, the chemical composition plays a crucial role in its properties. A36 steel is primarily made of iron, with small amounts of carbon, manganese, and other elements. Here’s a quick breakdown of its typical composition:

| Element | Percentage |

|---|---|

| Carbon (C) | 0.26% max |

| Manganese (Mn) | 0.60% – 0.90% |

| Phosphorus (P) | 0.04% max |

| Sulfur (S) | 0.05% max |

This composition contributes to its durability and resilience. A36 steel is also known for its excellent weldability. This means that it can be easily welded to other metals, making it a favorite among fabricators. Picture a puzzle; if the pieces fit together perfectly, the final picture is strong and seamless. That’s how A36 steel behaves when welded.

Moreover, A36 steel has a good balance of ductility and toughness. Ductility refers to how easily a material can be stretched or shaped without breaking. This quality allows A36 steel to be formed into various shapes and sizes without losing its integrity. Toughness, on the other hand, means it can absorb energy and deform without breaking. Think of it like a rubber band; it can stretch and bend but will return to its original shape without snapping.

In summary, A36 steel sheets are not just sheets of metal. They are a blend of strength, weldability, and durability. Whether you’re building a structure or manufacturing parts, understanding these properties can help you make informed decisions. So next time you consider A36 steel, remember its unique properties that make it a reliable choice!

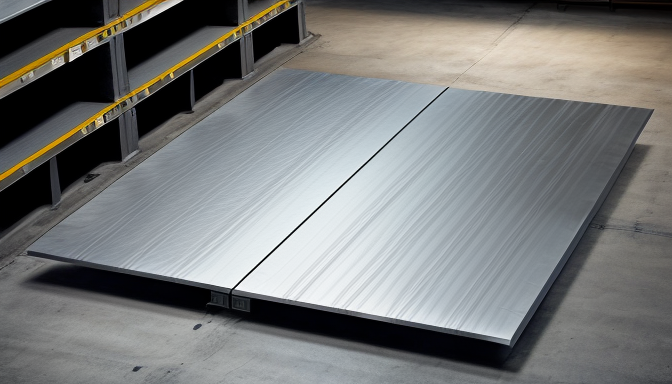

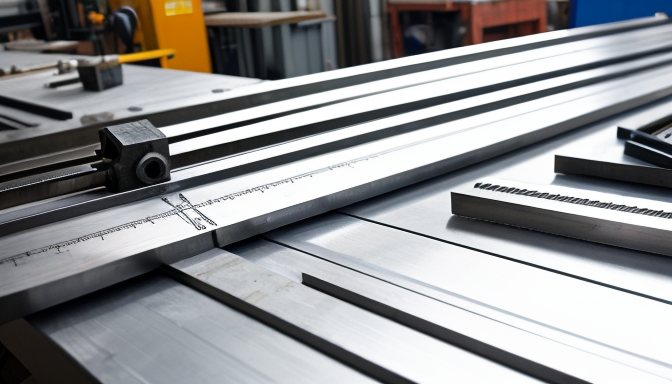

A36 Steel Sheet Sizes

A36 steel sheets are a popular choice in many industries due to their versatility and reliability. When it comes to sizes, these sheets are available in a variety of dimensions to meet different project needs. Understanding the sizes is crucial for ensuring that you select the right sheet for your application. Whether you’re working on a small DIY project or a large construction job, knowing the available sizes can make all the difference.

Typically, A36 steel sheets come in standard sizes, but many suppliers also offer custom sizing options. Standard dimensions usually include widths of 48 inches and lengths of 96 inches, though you can often find larger sheets, like 120 inches in length. Thickness is another important factor to consider. Common thicknesses range from 1/8 inch to 1 inch. This range allows you to choose the perfect sheet that suits your project’s requirements.

When selecting the size of your A36 steel sheet, think about the following:

- Project requirements: What are you building? Understanding the dimensions of your project will help you choose the right size.

- Weight considerations: Heavier sheets can be more challenging to handle and transport. Make sure you can manage the weight.

- Cutting and fabrication: If you need specific sizes, consider how much cutting or fabrication will be necessary. Custom sizes might save you time and effort.

To give you a clearer idea, here’s a simple table showcasing some standard sizes and thicknesses of A36 steel sheets:

| Thickness (inches) | Width (inches) | Length (inches) |

|---|---|---|

| 1/8 | 48 | 96 |

| 1/4 | 48 | 120 |

| 3/8 | 60 | 240 |

| 1/2 | 72 | 240 |

These sizes are just a starting point. Many suppliers can provide sheets in custom dimensions, so don’t hesitate to ask if you need something specific. It’s all about finding the right fit for your project. Remember, the right size can enhance the strength and durability of your work, so take your time and choose wisely.

In conclusion, A36 steel sheets come in various sizes and thicknesses to suit different applications. Whether you need standard dimensions or custom cuts, understanding your options will help you make an informed decision. So, before you dive into your project, take a moment to consider the size you truly need!

Frequently Asked Questions

- What is A36 steel sheet used for?

A36 steel sheets are incredibly versatile and are commonly used in construction, manufacturing, and various industrial applications. They serve as a foundational material for structural components, machinery, and even in the automotive industry.

- How is the price of A36 steel sheet determined?

The price of A36 steel sheets can vary based on several factors, including market demand, thickness, dimensions, and supplier pricing. Additionally, fluctuations in raw material costs can influence overall pricing, so it’s always good to shop around for the best deal.

- What are the standard sizes available for A36 steel sheets?

A36 steel sheets come in a range of standard sizes, typically including thicknesses from 1/8 inch to 1 inch and widths from 4 to 10 feet. Custom sizes can also be ordered to meet specific project requirements, making them adaptable for various applications.

- How can I calculate the weight of an A36 steel sheet?

To calculate the weight of an A36 steel sheet, you can use the formula: Weight Length x Width x Thickness x Density. The density of A36 steel is approximately 490 lbs/ft³. This calculation will help you plan for transportation and handling effectively.

- What are the mechanical properties of A36 steel?

A36 steel is known for its excellent mechanical properties, including a yield strength of 36,000 psi and a tensile strength of 58,000 to 80,000 psi. Its weldability and machinability make it a preferred choice for many structural applications.

- Can A36 steel sheets be welded?

Absolutely! One of the standout features of A36 steel is its excellent weldability. This makes it a popular choice for fabricators and builders who need to join steel components securely.