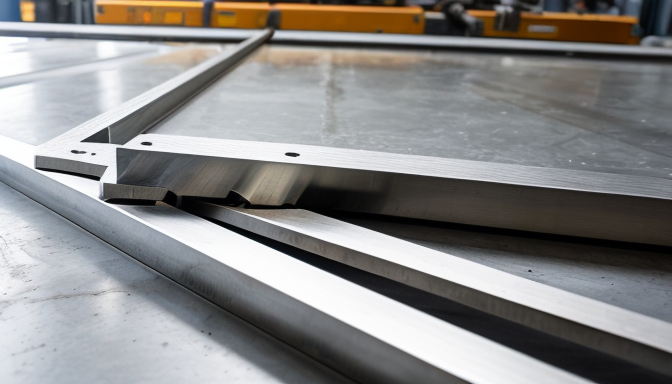

Steel flat bars are essential components in the world of construction and manufacturing. They are flat, rectangular pieces of steel that come in various sizes and thicknesses. These bars are known for their versatility and strength, making them a popular choice in many industries. From building frameworks to creating machinery, steel flat bars play a critical role in providing stability and support. Have you ever wondered how these simple-looking bars can be so powerful? Well, let’s dive into the details!

Understanding the pricing of steel flat bars is crucial for budgeting in construction and manufacturing projects. Prices can vary significantly based on several factors, including:

- Material Grade: Higher grades of steel often come with a higher price tag.

- Size and Thickness: Larger and thicker bars usually cost more.

- Market Demand: Prices can fluctuate based on supply and demand in the market.

On average, you can expect to pay anywhere from $0.50 to $2.00 per pound. However, keep in mind that bulk purchases might lead to discounts, which can help you save money on larger projects.

When working with steel flat bars, knowing their weight is important for engineering and construction. The weight of a steel flat bar can be calculated using a simple formula:

Weight (lbs) Length (ft) x Width (in) x Thickness (in) x 40.8

This formula considers the dimensions of the bar and gives you the weight in pounds. For example, a 10-foot long bar that is 4 inches wide and 0.25 inches thick would weigh approximately 102 pounds. Knowing the weight helps in planning for transportation and installation.

Steel flat bars possess unique properties that make them suitable for various applications. Here are some key characteristics:

- Strength: Steel flat bars are incredibly strong, able to withstand heavy loads without bending or breaking.

- Durability: They are designed to last, resisting wear and tear over time.

- Corrosion Resistance: Many steel flat bars are treated to resist rust and corrosion, extending their lifespan.

These properties make steel flat bars a reliable choice for construction, automotive, and manufacturing industries, among others.

Steel flat bars come in various sizes to accommodate different project requirements. Standard sizes typically range from 1 inch to 12 inches in width and 1/8 inch to 1 inch in thickness. However, if you have specific needs, many suppliers offer customization options. This flexibility allows engineers and builders to select the right size for their projects, ensuring optimal performance and safety.

Steel Flat Bar Price

Understanding the pricing of steel flat bars is crucial for budgeting in construction and manufacturing projects. Why? Because the cost can significantly affect your overall expenses. The price of steel flat bars can vary widely based on several factors. These include the type of steel, size, thickness, and market demand. For instance, if you need a thicker bar, you can expect to pay more. It’s like buying a larger pizza; the bigger it is, the more you’ll spend.

On average, the price range for steel flat bars can be anywhere from $0.50 to $3.00 per pound. However, this is just a ballpark figure. Prices can fluctuate based on the current market conditions. Here’s a quick breakdown of what influences these prices:

- Type of Steel: Different grades of steel have different costs. High-strength steel will generally cost more.

- Thickness and Width: Wider and thicker bars require more material, thus increasing the price.

- Market Demand: If there’s a surge in construction projects, prices might spike.

To give you a clearer picture, here’s a simple table that outlines average prices based on common sizes:

| Size (inches) | Weight (lbs per foot) | Average Price ($ per pound) |

|---|---|---|

| 1 x 1/4 | 0.31 | 1.00 |

| 2 x 1/4 | 0.62 | 1.20 |

| 3 x 1/4 | 0.93 | 1.50 |

When planning your budget, it’s also wise to consider shipping costs if you’re ordering in bulk. Some suppliers offer free shipping, while others may charge based on distance or weight. Always ask for a quote!

In conclusion, knowing the price of steel flat bars can save you from unexpected expenses down the line. It’s like knowing the cost of ingredients before you start cooking. Keep these factors in mind, and you’ll be better prepared to make informed decisions for your projects.

Steel Flat Bar Weight

Understanding the weight of steel flat bars is vital for anyone involved in construction or engineering. Why? Because the weight affects everything from transportation to structural integrity. Imagine lifting a heavy steel bar; if you don’t know its weight, you might be in for a surprise! So, how do we determine the weight of these bars? It’s simpler than you might think.

The weight of a steel flat bar can be calculated using a straightforward formula. The formula is:

Weight (lbs) Length (inches) x Width (inches) x Thickness (inches) x 0.2833

This formula gives you the weight in pounds. The 0.2833 factor comes from the density of steel, which is about 490 pounds per cubic foot. Let’s break this down. If you have a flat bar that is 10 feet long, 2 inches wide, and 0.25 inches thick, you’d first convert the length to inches (10 feet 120 inches). Then, plug the numbers into the formula:

Weight 120 x 2 x 0.25 x 0.2833 17 lbs

That’s a manageable weight for most projects. But what about larger bars? The weight can add up quickly. Here’s a quick reference for common sizes:

| Width (inches) | Thickness (inches) | Weight per foot (lbs) |

|---|---|---|

| 1 | 0.25 | 1.5 |

| 2 | 0.25 | 3.0 |

| 3 | 0.25 | 4.5 |

| 4 | 0.25 | 6.0 |

When planning your project, consider the total weight. It’s not just about the steel flat bars themselves; it’s about how they fit into your overall design. Heavy materials require stronger supports and can affect your budget. So, always keep an eye on the weight!

In my experience, knowing the weight helps avoid headaches down the line. I once worked on a project where we underestimated the weight of the steel. We had to scramble to find additional support beams. It was stressful! Learning from that, I now always calculate the weight first. It saves time and ensures safety.

In conclusion, calculating the weight of steel flat bars is not just a number game. It’s about making sure your project runs smoothly. Next time you’re working with steel, remember to weigh your options—literally!

Steel Flat Bar Properties

When it comes to steel flat bars, understanding their properties is key to knowing why they are so widely used in various industries. These bars are not just ordinary pieces of metal; they are engineered to deliver strength, durability, and versatility. Imagine needing a material that can withstand heavy loads and resist wear and tear. That’s where steel flat bars shine!

One of the most notable properties of steel flat bars is their strength. They are designed to bear significant weight, making them ideal for structural applications. Whether you’re building a bridge or a framework for a building, having a strong foundation is crucial. Steel flat bars provide that backbone, ensuring safety and reliability.

Another impressive feature is their durability. Steel is known for its ability to withstand harsh conditions. Whether it’s exposure to moisture, chemicals, or extreme temperatures, steel flat bars hold up remarkably well. This resistance to corrosion is particularly important in outdoor applications or in environments where the material might be exposed to the elements.

Let’s not forget about versatility. Steel flat bars can be cut, welded, and shaped to fit a wide range of applications. This adaptability makes them a favorite among engineers and builders. From manufacturing to construction, their uses are endless. Here are just a few:

- Support beams in buildings

- Frames for machinery

- Brackets and supports in various structures

- Parts in automotive and aerospace industries

But wait, there’s more! The finish of steel flat bars can also vary. You might find them in a hot-rolled finish, which is rough and ideal for structural use, or cold-rolled, which is smoother and often used for more aesthetic applications. This means you can choose the right type for your specific needs, adding another layer of flexibility.

In summary, the properties of steel flat bars—strength, durability, versatility, and finish options—make them a vital component in many industries. They are like the unsung heroes of construction and manufacturing. So, the next time you see a steel flat bar, remember, it’s not just metal; it’s a powerhouse of potential!

Steel Flat Bar Sizes

When it comes to steel flat bars, size matters. These bars are used in countless applications, from construction to manufacturing, and having the right size can make all the difference. Imagine trying to fit a square peg in a round hole; it just doesn’t work! Understanding the various sizes available ensures that you’ll find the perfect fit for your project.

Steel flat bars typically come in a range of widths and thicknesses. Common widths can vary from 1 inch to over 12 inches, while thicknesses often range from 1/8 inch to 1 inch. This variety allows for flexibility in design and application. But what does this mean for you?

Consider this: if you’re building a frame for a heavy structure, you might need a thicker bar to support the weight. On the other hand, if you’re crafting a decorative piece, a thinner bar might be more appropriate. It’s all about matching the size to the purpose. Here’s a quick overview of some standard sizes:

| Width (inches) | Thickness (inches) | Common Uses |

|---|---|---|

| 1 | 1/8 | Light frames, decorative elements |

| 2 | 1/4 | Supports, brackets |

| 4 | 1/2 | Structural applications |

| 6 | 3/4 | Heavy-duty frames |

| 12 | 1 | Industrial applications |

Many suppliers offer custom sizes as well. If you have a specific requirement, don’t hesitate to ask. Customization can save you time and money, ensuring that you get exactly what you need without compromising on quality.

In conclusion, when selecting steel flat bars, always consider the size in relation to your project needs. Whether you’re working on a small DIY project or a large-scale construction job, the right size will lead to better performance and durability. So, take your time, measure carefully, and choose wisely!

Frequently Asked Questions

- What is a steel flat bar?

A steel flat bar is a long, rectangular piece of steel that is flat on both sides. It is commonly used in construction, manufacturing, and various industrial applications due to its strength and versatility.

- How is the price of steel flat bars determined?

The price of steel flat bars can vary based on several factors, including the grade of steel, size, thickness, and market demand. Generally, prices fluctuate with changes in raw material costs and overall economic conditions.

- What are the typical weights of steel flat bars?

The weight of a steel flat bar depends on its dimensions and the density of the steel used. You can calculate the weight by multiplying the volume (length x width x thickness) by the density of steel, which is approximately 490 pounds per cubic foot.

- What properties make steel flat bars ideal for construction?

Steel flat bars are known for their high tensile strength, durability, and resistance to corrosion. These properties make them suitable for a range of applications, from structural support to decorative elements in buildings.

- Are steel flat bars available in different sizes?

Yes! Steel flat bars come in a variety of sizes and thicknesses. Standard dimensions are widely available, but many suppliers also offer customization options to meet specific project requirements.

- Can I use steel flat bars for outdoor projects?

Absolutely! Steel flat bars are often used in outdoor applications, but it’s essential to consider protective coatings or treatments to enhance their resistance to rust and corrosion when exposed to the elements.

- How do I choose the right steel flat bar for my project?

Choosing the right steel flat bar involves considering factors such as the load requirements, environmental conditions, and specific applications. Consulting with a supplier or engineer can provide valuable insights tailored to your needs.