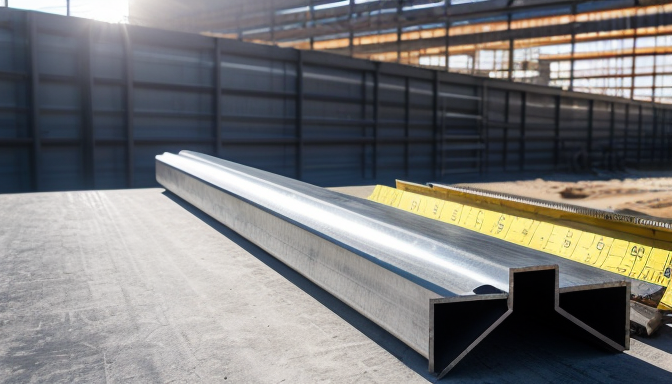

When it comes to construction, are the unsung heroes. They form the backbone of countless structures, from towering skyscrapers to humble homes. But what exactly are these profiles? Simply put, they are standardized shapes made from steel, designed to provide strength and support in various construction applications.

Think of steel profiles like the skeleton of a building. Just as our bones give us shape and support, these profiles hold up walls, roofs, and floors. They come in different shapes and sizes, each tailored for specific uses. You might be familiar with common types like I-beams, channels, and angles. Each type has its own unique properties and is chosen based on the demands of the project.

Why should you care about steel profiles? Well, if you’re involved in any construction work, understanding these profiles can save you time and money. They influence everything from the overall design to the cost of materials. Plus, knowing the right type to use can make all the difference in ensuring a project’s success.

In this article, we’ll explore various aspects of steel construction profiles, including their pricing, weight, properties, and sizes. By the end, you’ll have a comprehensive understanding of their significance in construction. So, whether you’re an architect, builder, or just curious about the construction world, stick around!

Steel Construction Profiles Price

Understanding the pricing of steel construction profiles is crucial for budgeting projects. After all, you don’t want to be caught off guard when the bill comes in, right? Several factors influence the cost of these profiles, and knowing them can help you make smarter decisions.

First off, the quality of the material plays a significant role. Higher quality steel often comes at a premium price. Think of it like buying a fancy coffee. You can get a decent cup for a few bucks, but a high-end brew will cost you more. The same goes for steel. If you want durability and strength, you might need to shell out a bit more.

Next, market demand can swing prices up or down. When construction booms, the demand for steel rises, leading to higher prices. Conversely, during slow periods, prices may drop. It’s a bit like the housing market—when everyone wants to buy, prices soar. Keep an eye on trends in the construction industry, as they can give you hints about when to buy.

Regional variations also affect pricing. Steel prices can differ from one location to another due to transportation costs or local supply and demand. For instance, if you’re in a remote area, shipping costs might inflate your prices. On the other hand, if you’re near a major supplier, you might snag a better deal. Always check with local suppliers to get the best price.

Here’s a quick breakdown of some factors that can influence the price of steel construction profiles:

- Material Quality: Higher quality typically means higher cost.

- Market Demand: Prices fluctuate based on demand.

- Regional Variations: Local supply can affect costs.

- Profile Type: Different profiles (like I-beams, C-channels) have varying prices.

In conclusion, knowing the factors that affect steel construction profiles’ prices can save you money in the long run. Whether you’re a contractor or a DIY enthusiast, being informed helps you make better choices. So, do your homework and shop around. It’s worth it to find the best deal for your project!

Steel Construction Profiles Weight

The weight of steel construction profiles plays a significant role in the overall design and execution of construction projects. It’s not just about how heavy they are; it’s about how that weight impacts everything from structural integrity to transportation logistics. Imagine trying to fit a heavy piece of machinery into a truck that can’t handle it. You see the problem? Weight matters.

When we talk about the weight of steel profiles, we’re looking at a variety of factors. First off, different profiles have different weights. For instance, an I-beam will weigh differently than a C-channel. This difference can affect how engineers plan a project. They need to consider not only the load the structure will bear but also how much the materials themselves will weigh.

To give you a clearer picture, let’s break it down. Here’s a simple table that shows the approximate weights of some common steel profiles:

| Profile Type | Weight (per meter) |

|---|---|

| I-Beam | 10 – 30 kg |

| C-Channel | 5 – 20 kg |

| Square Tube | 3 – 15 kg |

| Angle Iron | 2 – 12 kg |

As you can see, the weight varies quite a bit. This variance is crucial for construction teams. They need to plan for how these weights will affect the overall structure. Too heavy? You might need extra support. Too light? It might not hold up under stress.

Let’s not forget about transportation. Heavier profiles can lead to higher shipping costs. They require more robust vehicles and possibly special handling. It’s like ordering a large pizza; the bigger it is, the more you pay for delivery. So, understanding the weight of these profiles can help in budgeting and logistics.

In summary, the weight of steel construction profiles is a vital consideration in any building project. It influences design choices, affects costs, and impacts the logistics of getting materials on-site. So, the next time you see a construction site, think about how those steel beams are not just strong—they’re heavy, and that weight carries a lot of importance.

Steel Construction Profiles Properties

Steel construction profiles are not just metal shapes; they are the backbone of many structures. Their unique properties make them indispensable in the construction industry. Let’s dive into what makes these profiles so special and why they are the go-to choice for engineers and builders alike.

First off, let’s talk about strength. Steel is known for its impressive strength-to-weight ratio. This means it can support heavy loads without being overly bulky. Imagine trying to lift a car with a piece of cardboard. It just won’t work! Similarly, steel profiles can handle massive weight while remaining relatively light. This is crucial for high-rise buildings and bridges where every pound counts.

Next up is durability. Steel doesn’t just stand the test of time; it thrives in various environments. Whether it’s scorching heat, freezing cold, or even heavy rain, steel construction profiles hold their ground. They resist wear and tear better than many other materials. Think of them like that favorite pair of jeans that just gets better with age. You can count on steel to last, which ultimately saves costs in repairs and replacements.

Another key property is corrosion resistance. While steel can rust, advancements in technology have led to the creation of various coatings and treatments that enhance its resistance to corrosion. This is particularly important in areas with high humidity or salt exposure, like coastal regions. By using treated steel profiles, you’re ensuring that your structure won’t crumble at the first sign of moisture.

But it’s not just about strength and durability. Steel profiles are also incredibly versatile. They come in different shapes and sizes, making them suitable for a wide range of applications. From beams and columns to angles and channels, there’s a steel profile for nearly every construction need. This versatility allows architects and engineers to get creative, pushing the boundaries of design.

To sum it all up, here are the standout properties of steel construction profiles:

- Strength: Excellent strength-to-weight ratio.

- Durability: Long-lasting in various conditions.

- Corrosion Resistance: Enhanced with coatings for longevity.

- Versatility: Available in multiple shapes and sizes.

In conclusion, the properties of steel construction profiles make them a vital choice in modern construction. Their combination of strength, durability, corrosion resistance, and versatility ensures that they meet the demands of today’s engineering challenges. So, the next time you see a building or a bridge, remember the silent hero behind it—steel construction profiles.

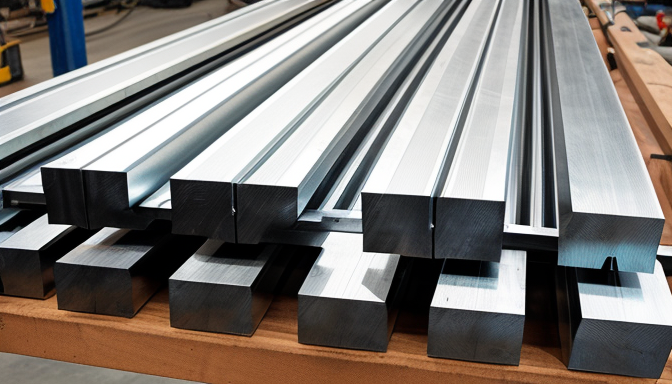

Steel Construction Profiles Sizes

When it comes to steel construction profiles, size truly matters. Choosing the right size can make or break a project. It’s like picking the perfect piece of clothing; too big or too small, and it just won’t fit right. Steel profiles come in various dimensions, each tailored to meet specific engineering needs. Understanding these sizes is essential for effective planning and execution.

Typically, steel construction profiles are categorized by their shapes and dimensions. Common shapes include I-beams, H-beams, channels, and angles. Each shape serves different purposes, and the dimensions can vary significantly. For instance, an I-beam might be ideal for supporting heavy loads in a skyscraper, while a channel might work better for lighter structures.

So, what sizes are we looking at? Here’s a quick breakdown of some standard dimensions:

| Profile Type | Standard Size (mm) | Weight (kg/m) |

|---|---|---|

| I-beam | 100 x 50 | 7.3 |

| H-beam | 200 x 100 | 14.5 |

| Channel | 75 x 40 | 4.5 |

| Angle | 50 x 50 | 3.2 |

These sizes are just the tip of the iceberg. Custom sizes are also available, allowing engineers to tailor profiles to their specific project requirements. Imagine needing a profile that fits perfectly into a unique architectural design. Custom sizes can provide that flexibility, making it easier to achieve the desired aesthetic and structural integrity.

Choosing the right size is not just about aesthetics; it also impacts load-bearing capacity and overall safety. A profile that is too small may not support the weight it needs to, leading to potential failures. On the other hand, oversizing can lead to unnecessary costs and complications. It’s a delicate balance, much like walking a tightrope.

In conclusion, understanding steel construction profile sizes is vital for anyone involved in construction. Whether you’re an architect sketching designs or a contractor planning logistics, knowing your dimensions can save time, money, and headaches down the line. So, the next time you’re faced with a steel profile choice, remember: size does matter!

Frequently Asked Questions

- What are steel construction profiles?

Steel construction profiles are standardized shapes made from steel, used in various construction projects. They come in different forms, such as beams, columns, and channels, and are essential for providing structural support and integrity.

- How is the price of steel construction profiles determined?

The price of steel construction profiles is influenced by several factors, including the quality of the steel, market demand, manufacturing processes, and regional variations. It’s important to compare prices from different suppliers to get the best deal for your project.

- What factors affect the weight of steel construction profiles?

The weight of steel construction profiles varies based on their dimensions and shape. Different profiles, like I-beams or C-channels, have unique weight specifications that can impact transportation and structural design. Understanding these weights is crucial for planning your construction project.

- What are the key properties of steel construction profiles?

Steel construction profiles are known for their high strength, durability, and resistance to corrosion. These properties make them ideal for use in demanding environments, ensuring that structures remain safe and reliable over time.

- What sizes are available for steel construction profiles?

Steel construction profiles come in a variety of standard sizes, but many manufacturers also offer customization options. Choosing the right size depends on the specific requirements of your project, including load capacity and design specifications.

- Can I customize steel construction profiles for my project?

Yes, many suppliers offer customization options for steel construction profiles. You can specify dimensions, shapes, and even material grades to fit your project’s unique needs. Just make sure to discuss your requirements with the supplier to ensure you get what you need.

- How do I choose the right steel construction profile for my application?

Choosing the right steel construction profile involves considering factors such as load requirements, environmental conditions, and design specifications. It might be helpful to consult with a structural engineer to ensure you select the most suitable profile for your project.