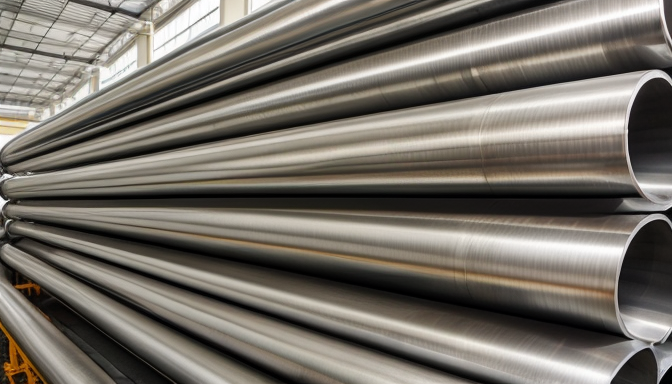

When it comes to industrial applications, stainless steel boiler pipes are a key player. These pipes are not just ordinary tubes; they are the backbone of many heating systems and power generation facilities. Imagine a world where steam and heat flow seamlessly through robust pipes, keeping everything running smoothly. That’s the magic of stainless steel boiler pipes. They are designed to handle high temperatures and pressures, making them essential in places like power plants, factories, and even in some residential systems.

But why choose stainless steel? Well, it’s all about the properties. Stainless steel is known for its incredible corrosion resistance. This means it can withstand harsh environments without rusting or degrading. Picture this: a pipe that can endure steam and chemicals without breaking down over time. That’s not just a pipe; that’s a reliable partner in your industrial setup.

Let’s dive a bit deeper into what makes these pipes so special. They are not just durable; they are also thermally conductive. This allows them to transfer heat efficiently, which is crucial in boiler systems where every bit of energy counts. You wouldn’t want heat escaping, right? Plus, they can handle extreme conditions without compromising their integrity, which is a huge plus in any high-pressure environment.

Now, if you’re wondering about the sizes available, you’re in for a treat. Stainless steel boiler pipes come in a variety of dimensions. Whether you need a small pipe for a compact system or a larger one for extensive industrial use, there’s a size that fits your needs. It’s like having a toolbox where every tool has a purpose. Choosing the right size is essential to ensure efficiency and safety in your applications.

In summary, stainless steel boiler pipes are more than just functional components; they are a blend of durability, efficiency, and versatility. They play a crucial role in various applications, ensuring that systems operate smoothly and effectively. Understanding their price, weight, properties, and sizes can help you make informed decisions for your projects. So, the next time you think about heating systems or industrial applications, remember the unsung hero—the stainless steel boiler pipe.

Stainless Steel Boiler Pipe Price

Understanding the price range of stainless steel boiler pipes is crucial for anyone involved in construction or manufacturing. You might be wondering, “What makes these pipes so expensive?” Well, several factors come into play. The material grade, size, and supplier can all significantly influence the cost. For instance, higher grades of stainless steel, which offer better durability and corrosion resistance, typically come with a higher price tag.

On average, you can expect to pay between $2 to $10 per foot for stainless steel boiler pipes. This price can vary based on the following:

- Material Grade: Different grades like 304 or 316 have different costs.

- Size: Larger pipes usually cost more due to the increased material used.

- Supplier: Prices can vary widely depending on where you purchase them.

Let’s break it down a bit more. For example, a standard 2-inch diameter pipe might cost around $3 to $5 per foot, while a larger 6-inch diameter pipe could range from $6 to $10 per foot. It’s a bit like shopping for clothes; the brand and quality can make a huge difference in price. If you’re looking for a bargain, shopping around is key. Different suppliers might offer discounts or bulk pricing that can save you a significant amount.

Another thing to keep in mind is the market demand. Prices can fluctuate based on global supply and demand. If there’s a surge in construction projects, for instance, the price of stainless steel might rise. Conversely, during slower economic times, you might find prices dropping. It’s always wise to keep an eye on market trends if you’re planning a large purchase.

In summary, while the price of stainless steel boiler pipes can seem daunting, understanding the factors that influence it can help you make informed decisions. Remember, investing in quality materials is usually worth it in the long run. After all, you wouldn’t want to compromise on safety and durability, would you?

Stainless Steel Boiler Pipe Weight

The weight of stainless steel boiler pipes is a critical factor in various stages of construction and manufacturing. Why does it matter? Well, the weight directly impacts transportation and installation processes. Imagine trying to lift a heavy pipe without the right equipment. It can be a hassle! Understanding the weight specifications helps in planning the logistics effectively.

Generally, the weight of these pipes can vary significantly based on their size and wall thickness. For instance, a larger diameter pipe will weigh more than a smaller one. But how do you know what to expect? Below is a simple table that outlines the weight of various sizes of stainless steel boiler pipes:

| Pipe Diameter (inches) | Wall Thickness (inches) | Weight (lbs per foot) |

|---|---|---|

| 1 | 0.065 | 0.68 |

| 2 | 0.065 | 1.50 |

| 3 | 0.065 | 2.27 |

| 4 | 0.065 | 3.25 |

| 6 | 0.065 | 4.56 |

As you can see, even a slight change in diameter or thickness can lead to a noticeable difference in weight. This is important to keep in mind when you’re selecting the right pipe for your project. You wouldn’t want to be caught off guard with a heavier pipe than expected!

Furthermore, the weight also affects the transportation costs. Heavier pipes may require special handling, which can add to your overall expenses. So, when you’re budgeting, don’t forget to factor in these weight considerations. It’s like packing for a trip; the heavier your suitcase, the more you might pay at the airport!

In summary, understanding the weight of stainless steel boiler pipes is essential for efficient planning and execution. It’s not just about choosing the right material; it’s also about ensuring that the logistics align with your project needs. Remember, a well-planned approach can save you both time and money!

Stainless Steel Boiler Pipe Properties

When it comes to stainless steel boiler pipes, their properties are nothing short of impressive. These pipes are designed to handle extreme conditions, making them essential in many industrial applications. But what exactly makes them so special? Let’s dive into their key characteristics.

First off, one of the standout features of stainless steel boiler pipes is their corrosion resistance. This means they can withstand harsh environments without rusting or degrading. Imagine a rainy day where everything gets wet and rusty. Now, think of stainless steel pipes standing strong, unaffected by the elements. This property is vital in industries like power generation and chemical processing, where exposure to corrosive substances is common.

Another important property is durability. Stainless steel is known for its strength. These pipes can endure high pressures and temperatures without bending or breaking. Picture a roller coaster that needs to support heavy loads while racing along the tracks. Similarly, stainless steel boiler pipes can handle the pressure of steam and hot water without faltering. This reliability ensures safety and efficiency in operations.

Let’s not forget about thermal conductivity. Stainless steel pipes can efficiently transfer heat, which is crucial in boiler applications. Think of a well-oiled machine that keeps everything running smoothly. The better the heat transfer, the more efficient the system. This property helps in maintaining optimal temperatures, which is essential for energy conservation.

Additionally, stainless steel boiler pipes come with a variety of grades, each offering different properties. For instance, Type 304 is often used for its excellent corrosion resistance, while Type 316 provides enhanced protection against chlorides. Choosing the right grade can make a significant difference in performance and longevity.

To give you a clearer picture, here’s a quick comparison of some common grades:

| Grade | Corrosion Resistance | Typical Applications |

|---|---|---|

| Type 304 | Good | Food processing, chemical equipment |

| Type 316 | Excellent | Marine applications, chemical storage |

| Type 321 | Very Good | Aerospace, high-temperature applications |

In summary, the properties of stainless steel boiler pipes—corrosion resistance, durability, and thermal conductivity—make them a top choice for various applications. Whether you’re in construction or manufacturing, understanding these properties can help you make informed decisions. After all, choosing the right materials can lead to safer and more efficient operations.

Stainless Steel Boiler Pipe Sizes

When it comes to stainless steel boiler pipes, size really matters. Choosing the right size is crucial, not just for fitting but also for ensuring efficiency in your systems. Imagine trying to fit a square peg in a round hole—frustrating, right? The same goes for boiler pipes. If the size is off, it can lead to leaks, inefficiencies, or even system failures. So, let’s dive into the world of sizes.

Stainless steel boiler pipes come in a variety of dimensions. They are typically measured in nominal pipe sizes (NPS), which can range from as small as 1/2 inch to as large as 36 inches or more. The most common sizes for industrial applications usually fall between 1 inch and 12 inches. But what does that mean for you? Well, it means you have options!

Here’s a quick breakdown of some common sizes:

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Wall Thickness |

|---|---|---|

| 1 inch | 1.315 inches | 0.133 inches |

| 2 inches | 2.375 inches | 0.154 inches |

| 3 inches | 3.500 inches | 0.216 inches |

| 4 inches | 4.500 inches | 0.237 inches |

| 6 inches | 6.625 inches | 0.280 inches |

Now, you might be wondering, how do you choose the right size for your project? Well, consider the following:

- Application: What will the pipe be used for? Different applications may require different sizes.

- Flow Rate: The size affects how much fluid can flow through. Larger pipes can handle more flow.

- Space Constraints: Sometimes, the space you have available will dictate the size you can use.

In my experience, I’ve seen projects go awry simply because the wrong size was chosen. One time, a friend of mine was working on a heating system and opted for a larger pipe than necessary. It turned out to be a costly mistake, leading to inefficiencies and increased energy bills. Lesson learned: always double-check your sizes!

In summary, selecting the right size of stainless steel boiler pipe is essential for ensuring a smooth operation. Take your time to assess your needs, and don’t hesitate to consult with professionals if you’re unsure. After all, a small mistake in sizing can lead to big problems down the line.

Frequently Asked Questions

- What is the average price of stainless steel boiler pipes?

The price of stainless steel boiler pipes can vary significantly based on factors like grade, size, and supplier. On average, you might expect to pay anywhere from $5 to $20 per foot, but it’s always wise to get quotes from multiple suppliers for the best deal.

- How much do stainless steel boiler pipes weigh?

The weight of stainless steel boiler pipes depends on their size and wall thickness. For instance, a 2-inch diameter pipe can weigh around 2.5 to 3.5 pounds per foot. Knowing the weight is essential for planning transportation and installation.

- What are the key properties of stainless steel boiler pipes?

Stainless steel boiler pipes are known for their exceptional corrosion resistance, durability, and thermal conductivity. These properties make them perfect for high-pressure and high-temperature applications, ensuring they can withstand tough conditions.

- What sizes do stainless steel boiler pipes come in?

Stainless steel boiler pipes are available in a wide range of sizes, typically from 1 inch to 12 inches in diameter. Choosing the right size is crucial for your specific application, whether it’s for residential heating or industrial processes.

- Can stainless steel boiler pipes be used for residential applications?

Absolutely! Stainless steel boiler pipes are versatile and can be used in residential heating systems, hot water systems, and even in some cooking appliances due to their high durability and resistance to rust.

- How do I maintain stainless steel boiler pipes?

Maintaining stainless steel boiler pipes is relatively easy. Regular inspections for signs of corrosion and ensuring that they are free from debris will help prolong their lifespan. If you notice any issues, addressing them promptly can prevent bigger problems down the line.