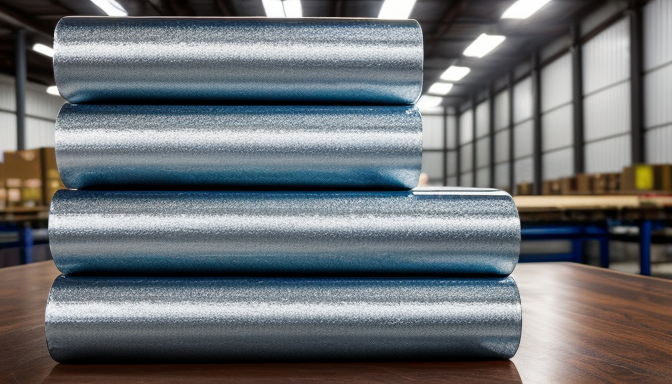

When it comes to industrial materials, few things are as versatile as pickled steel sheets. These sheets are not just any ordinary steel; they undergo a special process that enhances their properties. But what exactly is pickled steel? In simple terms, it’s steel that has been treated to remove rust, scale, and other impurities. This process not only improves its appearance but also boosts its durability. Imagine trying to paint a wall that’s covered in dirt. It wouldn’t stick well, right? The same goes for steel. Clean it up, and you get a surface that’s ready for action.

Pickled steel sheets are widely used across various industries. You’ll find them in construction, automotive, and even in manufacturing appliances. Why? Because they offer a combination of strength and flexibility. Think of them as the Swiss Army knife of steel products. They can be cut, shaped, and welded into different forms, making them ideal for countless applications.

Now, let’s talk about the price of pickled steel sheets. Understanding the factors that influence their cost is crucial for businesses. Prices can vary based on several factors, including:

- Market demand

- Thickness and size of the sheets

- Supplier location

- Current steel prices

By keeping an eye on these factors, businesses can make informed purchasing decisions. It’s like shopping for groceries; knowing when to buy in bulk can save you a lot of money.

Weight is another important aspect to consider. The weight of pickled steel sheets can affect transportation costs and structural calculations. For instance, a heavier sheet might require more robust handling equipment. Understanding the weight specifications can help in project planning, ensuring that everything runs smoothly.

Now, what about the properties of pickled steel sheets? They boast several unique characteristics that make them suitable for various applications:

- Corrosion Resistance: The pickling process enhances the steel’s ability to resist rust.

- Surface Finish: The sheets have a smooth finish, making them ideal for aesthetic applications.

- Weldability: They can be easily welded, allowing for versatile construction options.

These properties make pickled steel sheets a preferred choice for many industries. They not only perform well but also last longer, reducing the need for frequent replacements.

When it comes to sizes, pickled steel sheets are available in various dimensions. This means they can cater to different industrial needs. Whether you need a small sheet for a minor project or large sheets for significant construction, there’s an option available. Customization is often possible, allowing businesses to get exactly what they need.

In conclusion, pickled steel sheets are a fantastic material that combines functionality with durability. Understanding their price, weight, properties, and sizes can help you make better decisions. So, whether you’re in construction or manufacturing, consider what pickled steel sheets can do for you. They might just be the missing piece in your project puzzle.

Pickled Steel Sheet Price

Understanding the pricing of pickled steel sheets is essential for anyone involved in construction, manufacturing, or any industry that relies on metal products. Prices can fluctuate based on several factors, and being aware of these can help you make better purchasing decisions. So, what influences the cost?

First, let’s talk about the market trends. The demand for steel sheets often rises and falls with the economy. When construction booms, the need for pickled steel sheets increases, driving prices up. Conversely, in a downturn, prices may drop. It’s a classic case of supply and demand!

Next, consider the quality of the steel. Higher quality materials typically come with a higher price tag. Manufacturers often use different grades of steel for pickling, which can affect durability and performance. If you’re looking for something that lasts, investing in quality can save money in the long run.

Additionally, geographical location plays a role. Prices can vary significantly from one region to another. For instance, if you’re in an area where steel is scarce, you might find yourself paying more. On the flip side, regions with abundant steel production may offer lower prices.

Another factor is the size and thickness of the sheets. Larger or thicker sheets often cost more because they require more material and processing. Here’s a quick overview:

| Size (mm) | Approximate Price ($ per ton) |

|---|---|

| 1.0 | 500 |

| 2.0 | 600 |

| 3.0 | 700 |

Finally, don’t forget about shipping costs. If you’re ordering from a distant supplier, transportation can add to your overall expenses. It’s always a good idea to factor in these costs when budgeting for your project.

So, when it comes to pickled steel sheet prices, remember to consider all these factors. It’s not just about the sticker price. Look at the bigger picture. Compare suppliers, check for quality, and always keep an eye on market trends. This way, you’ll be in a better position to make informed choices for your business.

Pickled Steel Sheet Weight

The weight of pickled steel sheets is not just a number; it plays a crucial role in various aspects of construction and manufacturing. When businesses choose materials, understanding weight specifications can make or break a project. Why? Because the weight directly affects transportation costs, structural integrity, and even the design of the final product. Imagine trying to lift a heavy sheet of steel; if it’s too heavy for your equipment, it could lead to delays or even accidents.

Generally, the weight of pickled steel sheets can vary depending on their thickness and dimensions. For instance, a standard sheet measuring 4 feet by 8 feet can weigh anywhere from 40 to 100 pounds, depending on its gauge. Here’s a quick breakdown of weight by thickness:

| Thickness (inches) | Weight per Sheet (lbs) |

|---|---|

| 0.030 | 40 |

| 0.060 | 80 |

| 0.090 | 120 |

As you can see, the thicker the sheet, the heavier it becomes. This is important when planning transportation. If you’re not careful, you could end up with a truckload that exceeds weight limits. No one wants to pay extra fees or, worse, have to offload materials.

Moreover, the weight affects how you handle these sheets on-site. Lifting equipment must be rated for the weight of the sheets being used. If you’re working with a lighter gauge, it might be easier to maneuver, but that could also mean sacrificing some durability. So, it’s a balancing act. You want the right weight for your specific application.

In conclusion, knowing the weight of pickled steel sheets is essential for anyone involved in construction or manufacturing. It helps with planning, budgeting, and ensuring safety on-site. So, before you make that purchase, take a moment to consider how weight will impact your project. It could save you time, money, and a lot of headaches down the road.

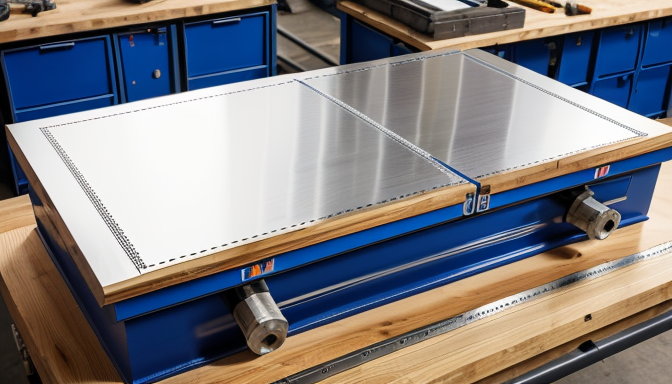

Pickled Steel Sheet Properties

When it comes to pickled steel sheets, their properties are what truly set them apart in the industrial world. These sheets are not just any ordinary steel; they are specially treated to enhance their performance. But what does that mean for you? Let’s dive into some of the key characteristics that make pickled steel sheets a top choice for many applications.

First off, one of the most impressive properties is their corrosion resistance. The pickling process removes oxides and other impurities from the surface of the steel. This not only improves the surface finish but also makes the steel less prone to rust. Imagine you have two pieces of steel: one is pickled and the other is not. Over time, the pickled steel will stand the test of time, while the untreated one may succumb to the elements. This makes it a fantastic option for outdoor applications or environments where moisture is a concern.

Another notable property is the surface finish. Pickled steel sheets have a smooth and clean surface, which is essential for many manufacturing processes. This smooth finish allows for better adhesion during painting or coating. It’s like preparing a canvas before painting; the smoother the surface, the better the final product will look. This quality is particularly important in industries where aesthetics matter, such as automotive and appliance manufacturing.

In terms of strength and durability, pickled steel sheets do not disappoint. They maintain the inherent strength of steel while benefiting from the pickling process. This means they can handle significant loads and stresses without compromising their integrity. Whether you’re constructing a building or manufacturing heavy machinery, knowing that your materials can withstand pressure is crucial.

Furthermore, pickled steel sheets are versatile. They come in various thicknesses and widths, making them suitable for a wide range of applications. From structural components to decorative elements, you can find a pickled steel sheet that fits your needs. It’s like having a Swiss Army knife in your toolbox; it’s ready for any task you throw at it!

To sum it up, here are the standout properties of pickled steel sheets:

- Corrosion Resistance: Less prone to rust and deterioration.

- Surface Finish: Smooth and clean, ideal for coatings.

- Strength and Durability: Capable of handling heavy loads.

- Versatility: Available in various sizes and thicknesses.

In conclusion, the properties of pickled steel sheets make them an essential material in many industries. Understanding these characteristics can help you make better choices for your projects, ensuring that you use materials that not only meet your needs but also enhance the overall quality of your work.

Pickled Steel Sheet Sizes

When it comes to pickled steel sheets, size matters. These sheets are available in a variety of dimensions, making them suitable for different industrial applications. Whether you’re in construction, manufacturing, or automotive industries, the right size ensures that your projects run smoothly. But what are the typical sizes you might encounter?

Standard sizes for pickled steel sheets often include:

- 4 ft x 8 ft

- 5 ft x 10 ft

- 6 ft x 12 ft

These dimensions are popular because they fit well into many designs and structures. However, it’s not just about the standard sizes. Many suppliers offer customization options to meet specific needs. If you have a unique project, you can request sheets cut to your exact specifications.

Now, let’s talk about thickness. Pickled steel sheets come in various thicknesses, typically ranging from 0.5 mm to 3 mm. The thickness you choose can greatly affect the sheet’s strength and weight. For instance, a thicker sheet is usually more durable, but it might also be heavier, which can impact shipping costs and handling. When planning your project, consider these factors carefully.

In terms of weight, a common calculation is that a standard 4 ft x 8 ft sheet can weigh anywhere from 50 to 100 pounds, depending on its thickness. This weight can affect how you transport and store the sheets. Always keep in mind the logistics involved in your projects.

In summary, whether you need standard sizes or custom dimensions, pickled steel sheets are versatile. They can be tailored to fit the needs of your project. Just remember to consider the thickness and weight, as these factors play a significant role in your overall planning. So, what size will you choose for your next project?

Frequently Asked Questions

- What is a pickled steel sheet?

A pickled steel sheet is a type of steel that has undergone a cleaning process to remove rust, scale, and other impurities. This process enhances its surface finish and prepares it for further processing or use in various applications.

- Why are pickled steel sheets important in industries?

Pickled steel sheets are crucial in industries because they offer excellent corrosion resistance, improved surface quality, and better weldability. These properties make them ideal for applications in automotive, construction, and manufacturing sectors.

- How does the weight of pickled steel sheets affect transportation?

The weight of pickled steel sheets is a key factor in transportation costs. Heavier sheets may require specialized handling and transportation methods, which can influence overall project budgets and logistics planning.

- What factors influence the price of pickled steel sheets?

Several factors can affect the price of pickled steel sheets, including market demand, raw material costs, and manufacturing processes. Staying informed about these trends can help businesses make better purchasing decisions.

- Are pickled steel sheets available in different sizes?

Yes, pickled steel sheets come in various sizes to meet diverse industrial needs. Standard dimensions are available, but customization options are also offered to cater to specific project requirements.

- How do I choose the right pickled steel sheet for my project?

Choosing the right pickled steel sheet depends on factors such as the intended application, required dimensions, and specific properties needed for performance. Consulting with suppliers can help you make an informed choice.

- Can pickled steel sheets be painted or coated?

Absolutely! Pickled steel sheets can be painted or coated to enhance their aesthetic appeal and further improve their corrosion resistance. Proper surface preparation is essential for optimal adhesion of paints and coatings.