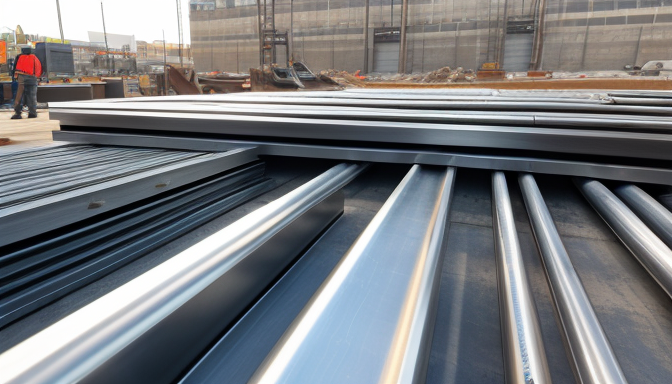

M Steel Profiles are a vital part of the construction and manufacturing industries. They are not just ordinary steel shapes; they are engineered to provide strength and durability. Imagine a backbone in a structure—without it, everything would collapse. That’s how important M Steel Profiles are. They come in various shapes and sizes, tailored to meet specific needs. Whether you are building a skyscraper or a simple warehouse, understanding M Steel Profiles can make all the difference.

These profiles are made from high-quality steel, offering exceptional performance. But what exactly are M Steel Profiles? They are typically used in beams, columns, and other structural applications. The “M” stands for “Mild Steel,” which is known for its excellent weldability and formability. This means that it can be shaped and molded into different forms without losing its strength. Think of it like clay in the hands of a sculptor—versatile and strong.

In the world of construction, using the right material is crucial. M Steel Profiles are not just about strength; they also offer flexibility in design. Builders can create structures that are not only safe but also aesthetically pleasing. This is why M Steel Profiles are favored by architects and engineers alike. They provide the perfect balance of cost-effectiveness and structural integrity.

But why should you care about M Steel Profiles? Well, if you are involved in any construction project, knowing about these profiles can save you time and money. You wouldn’t want to use a material that can’t support the weight of your project, would you? Understanding their properties, sizes, and prices can help you make informed choices.

In the following sections, we will dive deeper into the specifics of M Steel Profiles. We will explore:

- Price factors that influence the cost of M Steel Profiles.

- The significance of weight and how it affects construction.

- The unique properties that make M Steel Profiles suitable for various applications.

- Standard sizes available and how to choose the right one for your needs.

So, stay tuned! This information could be the key to ensuring your next project is a success. After all, in construction, knowledge is as important as the materials you use.

M Steel Profile Price

Understanding the pricing factors of M Steel Profiles helps consumers make informed decisions. When it comes to buying steel, price is often the first thing that pops into our heads. But why is it so important? Well, the price can vary greatly based on several factors, and knowing these can save you a lot of money. Think of it like shopping for a car; you wouldn’t just pick the first one you see without checking the features and prices, right?

The price of M Steel Profiles can fluctuate due to market trends and demand. For instance, during construction booms, prices might spike because more people are buying. Conversely, when demand drops, prices can fall. Here’s a quick breakdown of what influences the prices:

- Material Quality: Higher quality steel often comes at a higher price.

- Market Demand: If many projects are underway, expect prices to rise.

- Size and Thickness: Larger and thicker profiles typically cost more.

- Supplier Location: Proximity to suppliers can affect shipping costs.

It’s also worth noting that prices can vary from one supplier to another. This is where shopping around becomes essential. Just like you wouldn’t buy the first pair of shoes you see, don’t settle for the first quote you get. Compare prices from different suppliers to get the best deal.

| Profile Type | Price per Ton (Estimated) |

|---|---|

| Mild Steel Profile | $500 – $700 |

| High Strength Steel Profile | $800 – $1000 |

| Stainless Steel Profile | $1200 – $1500 |

When considering the price, don’t forget to factor in delivery costs and any additional fees. Sometimes, a lower price can come with hidden costs that can make the total much higher. Always ask for a detailed quote that includes everything.

In conclusion, knowing the price range and factors affecting M Steel Profiles is crucial for making a smart purchase. By doing your homework and comparing options, you can ensure you’re getting the best value for your money. After all, it’s not just about the price tag; it’s about the quality and value you receive in return.

M Steel Profile Weight

The weight of M Steel Profiles plays a pivotal role in construction and manufacturing. Why? Because it directly affects the structural integrity of a project. Think about it: if you’re building a bridge or a high-rise, the weight of the materials you use is crucial. Too heavy, and you risk overloading the structure. Too light, and it might not withstand the forces acting on it. It’s a balancing act!

When we talk about the weight of M Steel Profiles, we’re looking at a few key factors. First, the dimensions of the profile itself. Wider and thicker profiles will naturally weigh more. Second, the type of steel used. Different steel grades have varying densities, which can significantly impact overall weight. For example, a standard M Steel Profile might weigh differently based on whether it’s made from mild steel or a higher-grade alloy.

Knowing the weight specifications is not just about numbers; it’s about safety and efficiency. For instance, if you’re planning a construction project, understanding the weight of the M Steel Profiles can help you:

- Calculate load-bearing capacities.

- Determine transportation logistics.

- Estimate costs based on shipping weight.

To give you a clearer picture, let’s take a look at a sample weight chart for common M Steel Profile sizes:

| Profile Size (mm) | Weight (kg/m) |

|---|---|

| 100 x 50 | 7.5 |

| 150 x 75 | 12.0 |

| 200 x 100 | 15.5 |

This table provides a snapshot of how different sizes impact weight. If you’re working on a project, you can see how the choice of profile size can influence both the load it can carry and the overall weight of your construction. It’s essential to consider these factors early in the planning stage. After all, the last thing you want is to find out your materials are too heavy or too light once construction is underway.

In summary, understanding the weight of M Steel Profiles is more than just a technical detail; it’s a fundamental aspect of ensuring that your construction project is safe, efficient, and successful. So, the next time you’re selecting materials, remember to weigh your options—literally!

M Steel Profile Properties

M Steel Profiles are not just metal pieces; they are the backbone of many construction and manufacturing projects. Understanding their properties is crucial. Why? Because these properties determine how well they perform in various applications. Let’s dive into what makes M Steel Profiles stand out.

First off, let’s talk about mechanical properties. These include strength, ductility, and toughness. Strength is vital because it tells us how much load the steel can bear without deforming. Ductility is equally important; it allows the steel to be shaped without breaking. Imagine trying to bend a stiff piece of metal. If it snaps, that’s a problem! Toughness, on the other hand, is about how well the steel can absorb energy without fracturing. Think of it as the steel’s ability to take a hit and keep going.

Now, let’s not forget about the physical properties. These are just as essential. M Steel Profiles have a specific density, which affects their weight. Knowing the density helps in calculating the total weight of the structure. It’s like packing for a trip; if you know how much your suitcase weighs, you can plan better. Additionally, the thermal conductivity of M Steel is significant. It determines how well the material can conduct heat, which is crucial in applications where temperature control is necessary.

Here’s a quick overview of some key properties:

| Property | Description |

|---|---|

| Strength | Ability to withstand loads without deforming. |

| Ductility | Capability to be shaped without breaking. |

| Toughness | Resistance to fracturing under stress. |

| Density | Weight per unit volume, affecting overall structure weight. |

| Thermal Conductivity | Efficiency in conducting heat. |

In practical terms, these properties mean that M Steel Profiles can be used in a variety of situations. From skyscrapers to bridges, their strength and durability make them a go-to choice for builders. They can handle heavy loads and resist wear and tear over time. This is why you often see M Steel Profiles in load-bearing structures.

So, the next time you see a building or a bridge, think about the properties of the materials used. M Steel Profiles play a crucial role in ensuring safety and stability. They are more than just steel; they are engineered for performance and reliability.

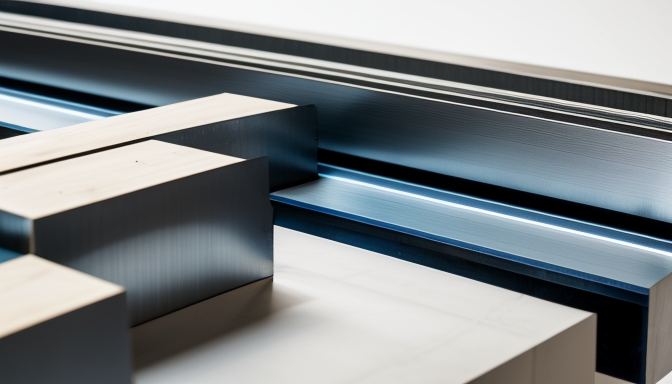

M Steel Profile Sizes

This article explores the various aspects of M Steel Profiles, including their price, weight, properties, sizes, and uses in construction and manufacturing industries.

Selecting the right size of M Steel Profiles is crucial for any construction or manufacturing project. Imagine trying to fit a square peg in a round hole. It just doesn’t work! Similarly, choosing the wrong size of steel profile can lead to structural issues and increased costs. So, how do you choose the right size? Well, it all starts with understanding your project requirements.

M Steel Profiles come in various sizes, each designed for specific applications. The standard sizes are usually categorized by their dimensions, which include width, height, and thickness. For instance, a common size might be 100mm x 50mm with a thickness of 5mm. These dimensions are essential because they determine how much weight the profile can support and how it will fit into your overall design.

Here’s a quick overview of some standard sizes:

| Size (mm) | Weight (kg/m) | Common Uses |

|---|---|---|

| 100 x 50 x 5 | 8.0 | Beams, frames |

| 150 x 75 x 6 | 12.5 | Support structures |

| 200 x 100 x 8 | 17.0 | Heavy-duty applications |

When selecting a size, consider the following:

- Load requirements: How much weight will the profile need to support?

- Space constraints: Does the size fit within your design?

- Material availability: Is the size readily available from suppliers?

In my experience, I’ve seen projects go sideways simply because the wrong size was chosen. A client once ordered profiles that were too small for a heavy framework, thinking they could save money. The result? They had to redo the entire structure, leading to wasted time and resources. So, take the time to assess your needs carefully.

In conclusion, choosing the right size of M Steel Profiles is not just a matter of preference; it’s a critical decision that impacts the success of your project. Whether you’re building a small shed or a massive industrial complex, understanding the sizes available will help you make informed choices and avoid costly mistakes.

Frequently Asked Questions

- What are M Steel Profiles used for?

M Steel Profiles are primarily used in construction and manufacturing. They provide structural support in buildings, bridges, and various industrial applications due to their strength and durability. Think of them as the backbone of a structure, holding everything together!

- How is the price of M Steel Profiles determined?

The price of M Steel Profiles can vary based on several factors, including market demand, raw material costs, and manufacturing processes. It’s like shopping for a smartphone; the latest features and brand reputation can influence the price significantly!

- Why is the weight of M Steel Profiles important?

The weight of M Steel Profiles is crucial for ensuring the structural integrity of a project. Knowing the weight helps engineers and builders calculate load-bearing capacities, much like how you’d check the weight limit on a bridge before crossing it!

- What are the standard sizes of M Steel Profiles?

M Steel Profiles come in various standard sizes, which are essential for meeting specific project requirements. Choosing the right size is like picking the perfect shoe; it needs to fit well to perform its best!

- What properties make M Steel Profiles unique?

M Steel Profiles possess unique mechanical and physical properties, such as high tensile strength and resistance to corrosion. These traits make them ideal for a variety of applications, similar to how certain materials are best for specific weather conditions!