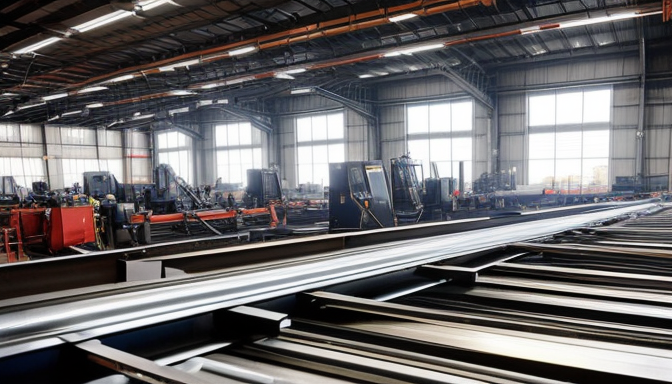

is a fundamental component in the construction and manufacturing industries. Its shape resembles the letter “L,” which provides excellent support and stability in various applications. Whether you’re building a sturdy framework for a new structure or creating a support system for machinery, L Steel Angle is often the go-to choice. Why? Because it’s versatile, reliable, and cost-effective.

Imagine trying to build a house without a solid foundation. You wouldn’t get very far, right? Similarly, L Steel Angle serves as a backbone in many projects. It’s not just about holding things up; it’s about ensuring that everything is aligned and secure. From bridges to buildings, this steel angle plays a crucial role in maintaining structural integrity.

But what makes it so special? First off, its strength is unmatched. L Steel Angle can withstand heavy loads, making it ideal for both residential and commercial uses. Additionally, it is durable, resisting wear and tear over time. This means that once you install it, you can trust it to do its job for years to come.

Moreover, L Steel Angle is resistant to environmental factors. Whether it’s rain, snow, or extreme temperatures, this material holds up well. This durability is essential, especially in construction, where exposure to the elements is inevitable. Think about it: would you want to use a material that might rust or degrade quickly? Of course not!

In terms of applications, the possibilities are vast. Here are a few common uses:

- Support beams in buildings

- Frames for windows and doors

- Brackets for shelving and storage

- Reinforcement for bridges and highways

Understanding the properties of L Steel Angle can help you make informed decisions for your projects. It’s not just about the angle itself, but how it integrates into your overall design. So, next time you’re in the hardware store or discussing plans with an architect, remember the importance of L Steel Angle. It’s more than just a piece of metal; it’s a critical element in creating strong, lasting structures.

L Steel Angle Price

Understanding the pricing factors of L Steel Angle is crucial for anyone involved in construction or manufacturing. After all, nobody wants to break the bank on materials. But what drives these prices? Well, several factors come into play. For starters, the size of the angle is a big one. Larger angles generally cost more due to the increased amount of steel used. Additionally, the quality of the steel can vary, which directly impacts pricing. Higher quality steel tends to be more expensive but offers better durability and strength.

Market trends also play a significant role in determining prices. For instance, if there’s a surge in construction projects, the demand for L Steel Angles might rise, leading to higher prices. Conversely, during economic downturns, prices may drop as demand falls. It’s a classic case of supply and demand. So, keeping an eye on market trends can help you make informed decisions.

To give you a clearer picture, let’s look at a simple table that outlines average prices based on size and quality:

| Size (inches) | Material Quality | Average Price (per foot) |

|---|---|---|

| 1 x 1 | Standard | $0.50 |

| 1 x 1 | High Quality | $0.75 |

| 2 x 2 | Standard | $1.00 |

| 2 x 2 | High Quality | $1.50 |

| 3 x 3 | Standard | $1.50 |

| 3 x 3 | High Quality | $2.00 |

As you can see from the table, size and quality significantly influence the price. If you’re planning a project, it’s wise to factor these costs into your budget early on. Think about it: overspending on materials can lead to financial strain later. By being aware of these pricing dynamics, you can make smarter choices.

In conclusion, the price of L Steel Angle is not just a random number. It’s a reflection of various factors including size, material quality, and market trends. So, before you dive into your next project, take the time to research and understand these elements. It’ll save you time, money, and headaches down the line.

L Steel Angle Weight

The weight of L Steel Angle plays a crucial role in construction and manufacturing projects. It influences everything from transportation costs to installation techniques. So, why does weight matter? Imagine trying to lift a heavy beam by yourself. If it’s too heavy, you’ll struggle, right? The same principle applies in construction. Knowing the weight of L Steel Angle helps in planning and ensures safety on-site.

When we talk about weight, it’s not just a number. It varies based on two main factors: size and material. Different dimensions will yield different weights. For example, a longer and thicker angle will naturally weigh more than a shorter, thinner one. This variability can affect how you budget for transport and labor. If you’re not careful, you could end up with unexpected costs. Here’s a quick breakdown of how weight can differ:

| Size (inches) | Weight (lbs per foot) |

|---|---|

| 1 x 1 x 1/8 | 0.66 |

| 2 x 2 x 1/4 | 3.65 |

| 3 x 3 x 3/8 | 6.70 |

| 4 x 4 x 1/2 | 10.20 |

As you can see from the table, the weight increases significantly with size. This can be a game-changer when planning your project. For instance, if you need to lift a heavier angle, you may need more workers or specialized equipment. Understanding these weight differences helps you make smarter choices.

Moreover, the material you choose also affects the weight. L Steel Angle is typically made from structural steel, which is strong yet relatively lightweight compared to other materials. This characteristic is a major plus. It allows for easier handling without sacrificing strength. So, when you’re selecting the right angle for your project, consider both the size and the material.

In conclusion, knowing the weight of L Steel Angle is not just a technical detail; it’s a vital piece of information that can influence your entire project. From budgeting to logistics, every aspect is intertwined with this simple measurement. So, the next time you plan a project involving L Steel Angle, remember to factor in the weight. It could save you time, money, and a lot of headaches!

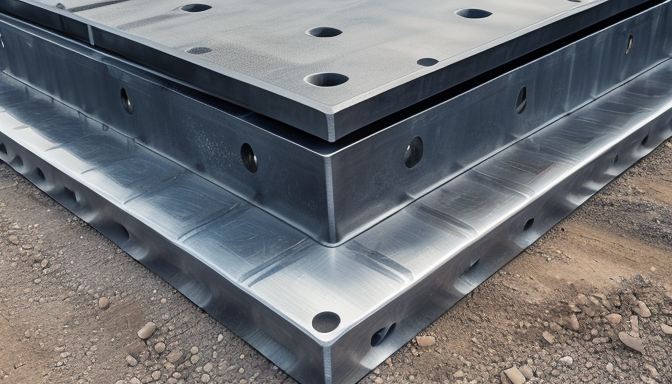

L Steel Angle Properties

L Steel Angle is a versatile and robust material widely used in construction and manufacturing. Its unique properties make it an excellent choice for various applications. But what exactly makes it stand out?

First off, let’s talk about strength. L Steel Angle is known for its high tensile strength. This means it can withstand heavy loads without bending or breaking. Imagine trying to hold up a heavy shelf. You’d want something strong, right? That’s what L Steel Angle offers. It’s like the backbone of a sturdy structure, providing essential support.

Next, there’s durability. This material is designed to last. Whether it’s exposed to rain, sun, or even snow, L Steel Angle holds up against the elements. It’s like your favorite pair of shoes that can go through anything but still look good. This durability makes it perfect for outdoor projects, where other materials might fail.

Another key property is its corrosion resistance. Many L Steel Angles are treated with protective coatings. This helps them resist rust and other forms of deterioration. Think about it: you wouldn’t want your materials to rust away after a few months. With L Steel Angle, you can rest easy knowing it is built to last.

Now, let’s not forget about versatility. L Steel Angle comes in various sizes and thicknesses. This means it can be used for everything from framing to brackets. Need something for a specific project? There’s likely an L Steel Angle that fits your needs perfectly. It’s like having a toolbox full of options, ready for any task.

To give you a clearer picture, here’s a quick table summarizing some key properties of L Steel Angle:

| Property | Description |

|---|---|

| Strength | High tensile strength for heavy load support |

| Durability | Long-lasting even in harsh environments |

| Corrosion Resistance | Protected against rust and deterioration |

| Versatility | Available in multiple sizes and thicknesses |

In summary, the properties of L Steel Angle make it an essential material in the construction and manufacturing industries. Its strength, durability, corrosion resistance, and versatility ensure it meets the demands of various projects. So, whether you’re building a new structure or repairing an old one, consider L Steel Angle. It might just be the perfect fit for your needs!

L Steel Angle Sizes

This article explores the various aspects of L Steel Angle, including its price, weight, properties, sizes, and uses in construction and manufacturing industries.

When it comes to construction, size matters. L Steel Angle comes in a variety of sizes, making it versatile for different projects. Whether you’re building a sturdy frame for a warehouse or crafting intricate designs for a residential home, there’s an angle that fits your needs. Understanding the dimensions is crucial for ensuring that your structure is both safe and efficient.

Typically, L Steel Angles are available in different leg lengths and thicknesses. The most common sizes range from 1 inch to 6 inches in leg length, with thicknesses varying from 1/8 inch to 1/2 inch. This variety allows builders to choose the right angle for both strength and aesthetic appeal. Here’s a quick breakdown:

| Leg Length (inches) | Thickness (inches) | Common Uses |

|---|---|---|

| 1 | 1/8 | Lightweight frames, small brackets |

| 2 | 1/4 | Medium-duty support structures |

| 3 | 3/8 | Heavy-duty applications, industrial uses |

| 4 | 1/2 | Large constructions, bridges |

| 6 | 1/2 | Extreme load-bearing structures |

Choosing the right size is not just about meeting the aesthetic requirements. It’s about ensuring that your project can withstand the test of time. For instance, if you’re constructing a frame for a building, using a thicker angle can provide more stability against wind and other environmental factors. It’s like choosing the right pair of shoes for a long hike; you want something that will support you without weighing you down.

Moreover, the size of the L Steel Angle also affects its weight. Heavier angles can be more challenging to handle during installation. Therefore, it’s essential to consider both the size and weight when planning your project logistics. Always remember to consult with your supplier to get the best advice on what size will work for your specific application.

In conclusion, the variety of sizes available in L Steel Angles offers flexibility for any construction project. Whether you need something lightweight or something that can handle heavy loads, there’s an angle that’s just right for you. So, the next time you’re planning a project, keep these sizes in mind. It could make all the difference!

Frequently Asked Questions

- What is L Steel Angle used for?

L Steel Angle is commonly used in construction and manufacturing for structural support. Its versatility allows it to be used in beams, frames, and brackets, making it an essential component in various projects.

- How do I determine the right size of L Steel Angle for my project?

Choosing the right size depends on the specific requirements of your project, including load-bearing needs and space constraints. It’s best to consult with a structural engineer or refer to project specifications to ensure you select the appropriate dimensions.

- What factors influence the price of L Steel Angle?

The price of L Steel Angle can vary based on several factors including material quality, size, and market demand. Additionally, fluctuations in steel prices and regional supply chains can also impact costs, so it’s wise to keep an eye on market trends.

- How much does L Steel Angle typically weigh?

The weight of L Steel Angle varies depending on its size and thickness. For instance, a larger angle will weigh more than a smaller one. It’s important to calculate the total weight for transportation and installation purposes to avoid any logistical challenges.

- Is L Steel Angle resistant to corrosion?

While L Steel Angle is strong and durable, it can be susceptible to corrosion if not properly treated or coated. For outdoor or high-moisture environments, consider using galvanized or stainless steel angles to enhance their resistance to environmental factors.

- Can L Steel Angle be welded?

Absolutely! L Steel Angle can be welded, which makes it a popular choice for various fabrication processes. Just ensure that the welding process is suitable for the specific type of steel you’re using to maintain structural integrity.