Galvanized steel sheets are a fascinating material that plays a vital role in many industries. Have you ever wondered what makes them so special? These sheets are coated with a layer of zinc, which protects them from rust and corrosion. This protective layer is like a superhero cape for the steel, keeping it safe from the elements. Whether you’re building a house, constructing a bridge, or manufacturing appliances, galvanized steel sheets are often the unsung heroes of the project.

But why should you care about galvanized steel sheets? Well, their versatility is one of their most appealing traits. They come in various sizes and thicknesses, making them suitable for a wide range of applications. From roofing to automotive parts, their uses are nearly endless. Plus, they are relatively lightweight, which helps keep transportation costs down. Imagine carrying a heavy steel sheet versus a lighter one; the difference can be significant!

Let’s dive a bit deeper into what makes galvanized steel sheets a preferred choice. One of the standout features is their corrosion resistance. In environments where moisture and harsh conditions are prevalent, these sheets shine. They can withstand rain, snow, and even salty air without deteriorating. This durability means they last longer, saving you money in the long run. Think of it like investing in a sturdy umbrella that won’t flip inside out in a storm.

In addition to their strength, galvanized steel sheets are also cost-effective. The price can vary based on several factors, such as market demand and the thickness of the coating. Generally, buyers can expect to find a range of prices, but the value they provide is often worth it. After all, who wouldn’t want a material that combines durability with affordability?

In summary, galvanized steel sheets are an essential component in construction and manufacturing. Their unique properties, including corrosion resistance and lightweight design, make them a go-to choice for many projects. As you explore your options for materials, consider how these sheets could fit into your plans. They might just be the perfect fit for your next big project!

Galvanized Steel Sheet Price

Understanding the price of galvanized steel sheets is essential for anyone in the construction or manufacturing industries. Prices can fluctuate based on several factors. Have you ever wondered why one sheet costs more than another? It often boils down to market conditions, the thickness of the sheet, and the weight of the coating used.

First off, let’s talk about market conditions. Prices can change daily based on supply and demand. When the demand for steel rises, prices typically follow suit. Conversely, if there’s a surplus of steel in the market, prices may drop. It’s a bit like buying groceries; prices can vary week by week based on what’s in season.

Next up is the thickness of the steel. Thicker sheets generally cost more. Why? Well, they require more raw material and are often more durable. Think of it like choosing between a lightweight jacket and a heavy winter coat. The winter coat will cost more because it’s built to withstand harsher conditions.

Another factor is the coating weight. The galvanized coating protects the steel from rust and corrosion. More coating means better protection, but it also drives up the price. If you’re working on a project that will be exposed to the elements, investing in a heavier coating might save you money in the long run by reducing maintenance costs.

To give you a clearer picture, here’s a simple breakdown of how these factors can influence prices:

| Factor | Price Influence |

|---|---|

| Market Conditions | Prices can increase or decrease based on supply and demand. |

| Thickness | Thicker sheets cost more due to the use of more material. |

| Coating Weight | Heavier coatings increase the price but offer better protection. |

In conclusion, when shopping for galvanized steel sheets, keep these factors in mind. It’s not just about the price tag; it’s about what you’re getting for your money. A lower price might seem appealing, but if it doesn’t meet your project’s needs, it could end up costing you more in the long run. So, always weigh your options carefully!

Galvanized Steel Sheet Weight

The weight of galvanized steel sheets plays a crucial role in many industries, especially in construction and manufacturing. Why is this important? Well, each project has its own set of requirements and understanding the weight can help in making informed decisions. For instance, heavier sheets might be more durable but can also lead to higher transportation costs. Isn’t it interesting how a simple number can influence so many factors?

When we talk about weight, we often think about thickness and size. Thicker sheets weigh more, and that’s a straightforward calculation. But there’s more to it. The coating weight also matters. This refers to the amount of zinc applied to the surface of the steel. A heavier coating means more protection against corrosion, but it also adds to the overall weight. It’s like putting on a heavy jacket; sure, it keeps you warm, but it’s not always easy to carry around.

Here’s a quick breakdown of how weight affects various aspects:

- Transportation Costs: Heavier sheets can increase shipping expenses.

- Structural Calculations: Knowing the weight helps engineers design safer structures.

- Installation: Lighter sheets are easier to handle, which can speed up the installation process.

To give you a clearer picture, let’s look at a simple table that shows the weight of different thicknesses of galvanized steel sheets:

| Thickness (mm) | Weight (kg/m²) |

|---|---|

| 0.5 | 3.2 |

| 0.7 | 4.5 |

| 1.0 | 6.0 |

As you can see from the table, even a small change in thickness can significantly impact the weight. This is why it’s essential for buyers to consider the specific needs of their projects. Are you working on a large building? You might want to opt for a thicker sheet for added strength. On the other hand, if you’re making smaller items, a lighter sheet could be the way to go.

In conclusion, the weight of galvanized steel sheets is not just a number; it’s a key factor in planning and execution. Whether you’re a contractor, architect, or DIY enthusiast, understanding this aspect can help you choose the right materials for your projects. So, the next time you’re selecting galvanized steel sheets, remember: it’s not just about what looks good; it’s about what works best!

Galvanized Steel Sheet Properties

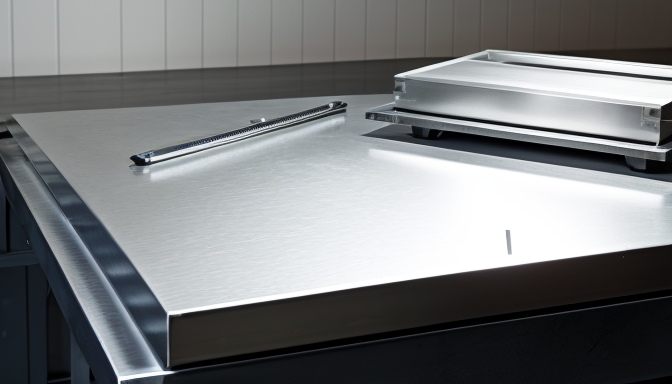

Galvanized steel sheets are not just ordinary metal sheets; they come with a unique set of properties that make them stand out in various industries. Imagine a shield that protects against the elements—that’s what galvanized steel does for your projects. The process of galvanization involves coating the steel with a layer of zinc, which provides excellent corrosion resistance. This means that when exposed to moisture and air, galvanized steel is less likely to rust compared to untreated steel.

Another remarkable property of galvanized steel sheets is their durability. These sheets can withstand harsh weather conditions, making them ideal for outdoor applications. Whether it’s rain, snow, or intense sunlight, galvanized steel holds up well, ensuring longevity. Think of it as a robust armor for your structures, providing peace of mind that your investment is protected.

In addition to corrosion resistance and durability, galvanized steel sheets are also versatile. They can be easily cut, shaped, and formed to fit various applications. This adaptability is crucial in industries such as construction, automotive, and manufacturing. For instance, they are commonly used in roofing, siding, and even in the production of appliances. Their ability to be tailored to specific needs means they can fit into almost any design without compromising strength.

One might wonder about the weight of these sheets. While weight can vary based on thickness and size, galvanized steel sheets are generally lightweight compared to other metal options. This characteristic not only makes them easier to handle but also reduces transportation costs. Imagine trying to lift heavy steel sheets; it can be quite a workout! With galvanized sheets, you save energy and effort.

Lastly, let’s not forget about the environmental benefits. The zinc used in the galvanization process is recyclable, making these sheets a more sustainable choice. As the world moves towards greener solutions, opting for galvanized steel can be a step in the right direction. You’re not just choosing a product; you’re making a choice that benefits the planet.

In summary, the properties of galvanized steel sheets—corrosion resistance, durability, versatility, lightweight nature, and environmental friendliness—make them an excellent choice for various applications. Whether you’re building a home, manufacturing appliances, or working on a construction project, these sheets offer a reliable solution that stands the test of time.

Galvanized Steel Sheet Sizes

When it comes to galvanized steel sheets, size matters. These sheets are not one-size-fits-all. They come in a variety of dimensions to fit different needs. Whether you’re working on a small DIY project or a large-scale construction job, knowing the right size is crucial.

Typically, galvanized steel sheets are available in standard sizes. But guess what? You can also get them customized! This flexibility is a game changer for designers and builders alike. Imagine trying to fit a square peg into a round hole. That’s what using the wrong sheet size feels like. With the right dimensions, everything fits perfectly!

Here are some common sizes you might encounter:

- 4 x 8 feet

- 5 x 10 feet

- 3 x 10 feet

These sizes are just the tip of the iceberg. Depending on your project, you might need something different. For example, if you’re creating a custom metal roof, you might require longer sheets. The beauty of galvanized steel is its adaptability. You can often order sheets in various thicknesses, too! This means you can get the durability you need without compromising on size.

But wait, there’s more! The thickness of the sheet can also affect its weight and performance. Thicker sheets provide better strength, while thinner ones are easier to handle and install. It’s like choosing between a heavyweight boxer and a lightweight one. Each has its strengths, but the choice depends on the match you’re preparing for.

To help visualize this, let’s look at a simple table that summarizes the relationship between size and thickness:

| Size (ft) | Thickness (gauge) | Weight (lbs) |

|---|---|---|

| 4 x 8 | 20 | 50 |

| 5 x 10 | 18 | 75 |

| 3 x 10 | 22 | 40 |

In summary, choosing the right size of galvanized steel sheets is essential for your project’s success. Think about what you need. Consider the dimensions, thickness, and weight. When you get it right, you set yourself up for a smoother installation process and a more durable outcome. So, the next time you’re in the market for galvanized steel, remember: size is not just a number; it’s the foundation of your project!

Frequently Asked Questions

- What is galvanized steel sheet?

Galvanized steel sheet is a type of steel that has been coated with a layer of zinc to protect it from corrosion. This process enhances its durability, making it ideal for use in various industries, especially where exposure to moisture is a concern.

- How is the price of galvanized steel sheets determined?

The price of galvanized steel sheets can fluctuate based on several factors including market demand, thickness of the sheet, and the weight of the zinc coating. It’s essential to compare prices from different suppliers to get the best deal.

- What are the common applications of galvanized steel sheets?

Galvanized steel sheets are widely used in construction, automotive, and manufacturing industries. They are commonly found in roofing, siding, and even in the production of appliances due to their corrosion-resistant properties.

- What sizes are available for galvanized steel sheets?

Galvanized steel sheets come in a variety of sizes and can often be customized to meet specific project requirements. This versatility allows them to be used in a wide range of applications.

- How does the weight of galvanized steel sheets affect construction?

The weight of galvanized steel sheets is a crucial factor in construction as it impacts transportation costs and structural calculations. Lighter sheets can reduce overall project weight, which can be beneficial in many applications.

- Are galvanized steel sheets environmentally friendly?

Yes, galvanized steel sheets are considered environmentally friendly because they are recyclable. The zinc coating can also help extend the life of the steel, reducing the need for frequent replacements and waste.