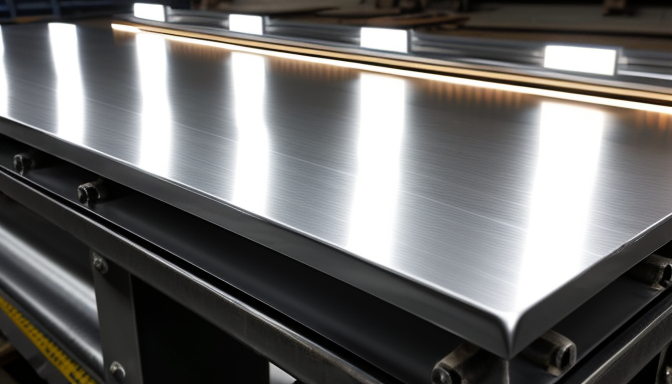

When it comes to industrial materials, DD12 steel sheets stand out for their versatility and strength. These sheets are made from a high-quality steel that is known for its excellent formability and weldability. If you’re in the manufacturing sector, you might already know how crucial it is to choose the right material for your projects. But what makes DD12 special? Let’s dive into its features, pricing, weight, properties, sizes, and applications.

DD12 steel is primarily used in the automotive and manufacturing industries. Why? Because it offers a perfect balance of strength and ductility. This means it can be shaped and molded into various forms without cracking. Imagine trying to make a complex shape out of a brittle material—it just wouldn’t work! DD12, however, allows for intricate designs, making it a go-to choice for many engineers and manufacturers.

In terms of pricing, DD12 steel sheets can vary based on several factors. Market demand, thickness, and size all play a role in determining the cost. If you’re budgeting for a project, it’s wise to keep an eye on current market trends. For instance, during high demand periods, prices may spike. Understanding these dynamics can help you plan better and avoid surprises.

Now, let’s talk about weight. The weight of DD12 steel sheets is significant, especially when considering transportation and handling. The weight is calculated based on the dimensions and thickness of the sheet. For example, a thicker sheet will naturally weigh more than a thinner one. This is an important consideration for logistics. If you’re shipping large quantities, knowing the weight can help you estimate shipping costs and choose the right transport options.

What about the properties of DD12 steel sheets? They have unique mechanical properties that make them suitable for a wide range of applications. Here are a few key characteristics:

- High tensile strength: This allows the steel to withstand heavy loads.

- Excellent formability: Makes it easy to bend and shape.

- Good weldability: Ideal for construction and assembly.

DD12 sheets come in various sizes to meet specific project needs. Whether you require standard dimensions or custom sizes, there’s likely an option that fits your requirements. This flexibility is crucial for manufacturers who need precise measurements for their products.

Finally, let’s explore the applications of DD12 steel sheets. Their adaptability means they can be found in numerous industries, including:

- Automotive manufacturing

- Construction

- Appliance manufacturing

In summary, DD12 steel sheets are a vital component in many manufacturing processes. Their unique properties, coupled with their availability in various sizes and weights, make them a reliable choice for industries that demand quality and performance. If you’re looking for a material that combines strength with formability, DD12 steel sheets are definitely worth considering.

DD12 Steel Sheet Price

Understanding the pricing structure of DD12 steel sheets is essential for anyone involved in manufacturing or construction. Prices can vary widely based on several factors. So, what influences these costs? Let’s dive in!

First off, the market demand plays a huge role. When demand is high, prices tend to climb. Conversely, when supply exceeds demand, you might find some great deals. It’s a bit like the weather; sometimes it’s sunny, and sometimes it rains. Keeping an eye on market trends can help you make informed decisions.

Another factor is the quality of the steel. Not all DD12 sheets are created equal. Higher quality often comes with a higher price tag. Think of it like buying a smartphone. You can get a basic model for cheap, but if you want the latest features, you’ll have to pay more. The same principle applies here.

Additionally, the supplier you choose can affect pricing. Different suppliers have different pricing strategies. Some might offer discounts for bulk purchases, while others might have a flat rate. It’s worth shopping around. Compare prices from multiple suppliers to find the best deal.

Here’s a quick overview of factors influencing DD12 steel sheet prices:

- Market Demand: High demand higher prices

- Quality: Higher quality higher costs

- Supplier Variability: Different suppliers, different prices

To give you a better idea, here’s a simple table showing estimated prices based on thickness:

| Thickness (mm) | Price per Sheet ($) |

|---|---|

| 1.0 | 50 |

| 2.0 | 90 |

| 3.0 | 120 |

These prices are just estimates and can fluctuate. Always check with your local suppliers for the most accurate and up-to-date pricing.

In conclusion, understanding the pricing of DD12 steel sheets is crucial. Keep an eye on demand, quality, and supplier options. This knowledge will empower you to make smart purchasing decisions. After all, in the world of steel, every dollar counts!

DD12 Steel Sheet Weight

When it comes to DD12 steel sheets, understanding their weight is crucial. Why? Because weight affects everything from transportation costs to the structural integrity of the final product. Knowing how to calculate the weight of these sheets can save you a lot of headaches down the road.

The weight of a steel sheet can be calculated using a straightforward formula. It’s based on the sheet’s dimensions and the density of the steel. The density of DD12 steel is approximately 7.85 g/cm³. To find the weight, you can use the formula:

Weight (kg) Length (m) × Width (m) × Thickness (m) × Density (kg/m³)

Let’s break this down a bit. If you have a DD12 steel sheet that measures 2 meters in length, 1 meter in width, and 0.01 meters in thickness, the calculation would look like this:

Weight 2 × 1 × 0.01 × 7850 157 kg

So, that sheet would weigh about 157 kilograms. This example illustrates how simple math can help you estimate weight accurately.

But why does weight matter? Here are a few reasons:

- Transportation Costs: Heavier sheets may cost more to ship. Knowing the weight helps you budget.

- Handling and Installation: The weight impacts how easy or hard it is to handle and install the sheets.

- Structural Requirements: In construction, knowing the weight helps ensure that structures can support the materials used.

In industries like automotive and construction, where DD12 steel sheets are frequently utilized, understanding weight can lead to better project planning. For instance, if you’re working on a large-scale project, calculating the total weight of multiple sheets can help in determining the right equipment for lifting and moving them safely.

In summary, the weight of DD12 steel sheets is not just a number; it’s a key factor that influences various aspects of manufacturing and construction. By grasping the weight implications, you can make informed decisions that enhance efficiency and safety in your projects.

DD12 Steel Sheet Properties

When it comes to selecting materials for manufacturing, understanding the properties of DD12 steel sheets is crucial. These sheets are not just any ordinary steel; they come with a unique set of characteristics that make them stand out in various applications. So, what exactly makes DD12 steel sheets so special?

First off, let’s talk about mechanical properties. DD12 steel sheets are known for their excellent formability. This means they can be easily shaped and molded without losing their strength. Imagine trying to bend a thick piece of metal. It’s tough, right? But with DD12, you get the flexibility needed for intricate designs. This property is vital in industries like automotive manufacturing, where complex shapes are a must.

Next up is the thermal property. DD12 steel sheets can withstand high temperatures, making them suitable for applications where heat resistance is essential. Think about a car engine or a heavy-duty machine. These environments can get pretty hot, and you need materials that won’t buckle under pressure. DD12 shines here, offering durability and reliability.

Now, let’s not forget about chemical properties. DD12 steel sheets have good resistance to corrosion, which is a significant advantage. Picture this: you’re building a structure that will be exposed to the elements. You wouldn’t want your materials rusting away, would you? With DD12, you get peace of mind knowing that your investment is protected against environmental wear and tear.

To summarize, here are the key properties of DD12 steel sheets:

- Formability: Easily shaped for complex designs.

- Thermal Resistance: Withstands high temperatures.

- Chemical Resistance: Good against corrosion.

These properties make DD12 steel sheets a popular choice across various industries. Whether it’s for automotive parts, construction, or machinery, the versatility of DD12 is hard to beat. It’s like having a Swiss Army knife in your toolbox—ready for any challenge that comes your way!

In conclusion, understanding the properties of DD12 steel sheets is essential for anyone involved in manufacturing or construction. Their unique combination of mechanical, thermal, and chemical properties not only enhances performance but also ensures longevity in various applications. So, next time you’re in the market for steel, consider the benefits that DD12 brings to the table.

DD12 Steel Sheet Sizes

When it comes to DD12 steel sheets, size matters. The dimensions you choose can significantly affect your project’s success. Whether you’re working on a small fabrication job or a large industrial application, understanding the available sizes is crucial. So, what sizes can you expect?

DD12 steel sheets are typically available in a variety of standard dimensions. These sizes are designed to meet the needs of different industries, ensuring that you can find the right fit for your specific requirements. Commonly, you will find sheets that are:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 1.0 | 1000 | 2000 |

| 1.5 | 1250 | 2500 |

| 2.0 | 1500 | 3000 |

| 3.0 | 2000 | 4000 |

These dimensions are just a starting point. Many suppliers offer custom sizes to accommodate unique project needs. If you’re looking for something specific, don’t hesitate to ask your supplier about custom options. They can often provide tailored solutions that fit your exact specifications.

Choosing the right size is not just about fitting your project; it’s also about efficiency. Larger sheets can reduce waste, as fewer cuts are needed. On the flip side, smaller sizes might be easier to handle and transport, especially for smaller projects. Think about your specific needs. Are you working in a tight space? Or do you have the capacity to manage larger sheets?

In addition to standard and custom sizes, it’s essential to consider the weight of the sheets. Heavier sheets might require special handling equipment, while lighter options could be more manageable. Always factor in the weight when planning your project logistics.

In summary, understanding the sizes available for DD12 steel sheets is key to successful project execution. Always consider your specific needs, the application, and how the size will affect your overall workflow. With the right size in hand, you can ensure that your project runs smoothly and efficiently.

DD12 Steel Sheet Applications

DD12 steel sheets are like the Swiss Army knife of the metal world. They are incredibly versatile and find their way into numerous industries. From automotive to construction, their adaptability makes them a favorite among manufacturers.

In the automotive industry, DD12 steel sheets are used primarily for body parts. Why? Because they offer a great balance of strength and formability. This means they can be shaped into complex designs without cracking. Think about the sleek curves of a car—those are often crafted from DD12 steel. It’s not just about looks; these sheets also help in keeping the vehicle lightweight, which is crucial for fuel efficiency.

Moving on to the construction sector, DD12 steel sheets play an essential role in fabricating structures. They are used in making frames, panels, and even roofing materials. Their ability to withstand various weather conditions while maintaining structural integrity is a significant plus. Imagine a building standing tall against harsh winds or heavy rain; DD12 steel sheets contribute to that resilience.

But that’s not all! These steel sheets are also prevalent in the manufacturing of appliances. From washing machines to refrigerators, DD12 steel is often chosen for its durability and aesthetic appeal. Home appliances need to be robust yet stylish, and DD12 delivers on both fronts.

Additionally, DD12 steel sheets are utilized in the production of various industrial equipment. This includes machinery parts that require high strength and toughness. In industries like oil and gas, where equipment faces extreme conditions, DD12 steel sheets are a reliable choice. They can handle the pressure, literally!

Here’s a quick look at some of the key applications of DD12 steel sheets:

- Automotive body parts

- Construction frames and panels

- Home appliances

- Industrial machinery

In summary, the applications of DD12 steel sheets are vast and varied. Their unique properties make them suitable for a wide range of uses, ensuring they are a staple in multiple industries. Whether you’re driving a car, living in a sturdy house, or using a reliable appliance, DD12 steel sheets are likely playing a crucial role behind the scenes.

Frequently Asked Questions

- What is DD12 steel sheet used for?

DD12 steel sheets are widely used in various manufacturing processes due to their excellent formability and weldability. They are ideal for applications in the automotive and construction industries, where strength and durability are crucial.

- How is the price of DD12 steel sheet determined?

The price of DD12 steel sheets can vary based on several factors, including market demand, the thickness of the sheet, and the supplier’s pricing strategy. It’s essential to compare prices from different suppliers to get the best deal.

- What are the typical sizes available for DD12 steel sheets?

DD12 steel sheets come in various standard sizes, but they can also be customized to meet specific project requirements. Common thicknesses range from 1mm to 20mm, with widths and lengths varying based on supplier offerings.

- What properties make DD12 steel sheets unique?

DD12 steel sheets are known for their excellent mechanical properties, including high tensile strength and good elongation. They also exhibit great thermal and chemical resistance, making them suitable for challenging environments.

- How does the weight of DD12 steel sheets affect their use?

The weight of DD12 steel sheets is a significant factor in their transportation and application. Heavier sheets may require specialized handling equipment, while lighter sheets can be more easily managed, affecting project logistics and costs.

- Can DD12 steel sheets be recycled?

Absolutely! DD12 steel sheets are fully recyclable, making them an environmentally friendly choice for manufacturers. Recycling helps reduce waste and conserves resources, aligning with sustainable manufacturing practices.