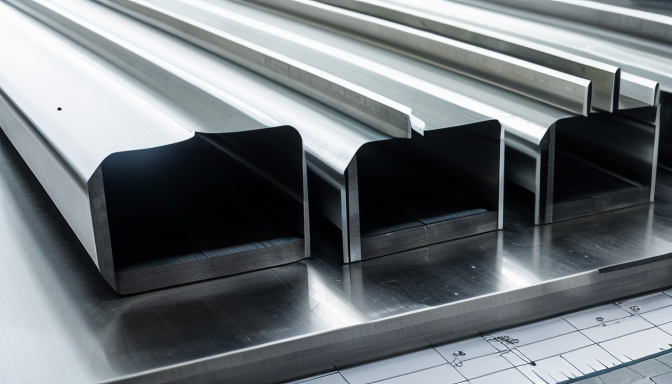

When it comes to construction and manufacturing, cold rolled steel profiles are a big deal. They are not just any steel; they are crafted through a unique process that enhances their strength and durability. Imagine shaping a piece of soft clay into a strong sculpture. That’s what cold rolling does to steel. It takes raw steel and transforms it into a product that can withstand a lot of pressure and weight.

But why should you care about these profiles? Well, they play a crucial role in various industries, from building skyscrapers to manufacturing car parts. Their versatility is impressive. You can find them in beams, channels, and angles, each serving a specific purpose. For instance, beams are used to support structures, while channels and angles are often used in framing and bracing.

Now, let’s dive deeper into what makes cold rolled steel profiles so special. The manufacturing process involves rolling the steel at room temperature, which gives it a smooth finish and enhanced strength. This process not only makes the steel more robust but also allows for tighter tolerances in dimensions. It’s like having a perfectly tailored suit instead of a baggy one.

In terms of applications, the possibilities are endless. Cold rolled steel profiles are used in:

- Construction of buildings and bridges

- Automotive manufacturing

- Furniture production

- Appliance manufacturing

Each of these applications benefits from the unique properties of cold rolled steel. For example, in construction, the strength-to-weight ratio of these profiles allows for sturdy structures without excessive weight. This is crucial in ensuring safety and efficiency.

But hold on! What about the different sizes available? Cold rolled steel profiles come in a variety of sizes, making them suitable for numerous projects. Whether you need a small angle for a DIY project or large beams for a commercial building, there’s likely a cold rolled steel profile that fits your needs.

In summary, cold rolled steel profiles are essential components in many industries. Their unique properties, wide range of sizes, and various applications make them a go-to choice for manufacturers and builders alike. Understanding these profiles can help you make informed decisions, whether you’re budgeting for a project or selecting materials for construction. So next time you see a building or a car, think about the cold rolled steel profiles that make them strong and reliable!

DKP Steel Profile Price

Understanding the pricing structure of DKP steel profiles is crucial for budgeting and project planning. Prices can vary widely based on several factors. Think of it like shopping for groceries. Sometimes, the same item can cost more at different stores. The same goes for DKP steel profiles.

First off, market demand plays a significant role. When more people want steel, prices tend to rise. Conversely, if demand drops, prices might fall. It’s a classic case of supply and demand. Next, the production processes used also influence costs. High-quality manufacturing methods may increase the price but often lead to better performance.

Another factor to consider is regional price variations. Prices can differ from one area to another due to transportation costs, local demand, and even labor rates. For example, if you’re in a remote location, shipping costs can add a hefty amount to your final price. So, it’s wise to shop around.

To give you a clearer picture, here’s a simplified table showing average prices for different types of DKP steel profiles:

| Profile Type | Average Price per Ton |

|---|---|

| Flat Bars | $600 – $800 |

| Angle Bars | $700 – $900 |

| Channels | $650 – $850 |

| Hollow Sections | $800 – $1000 |

As you can see from the table, prices can range significantly based on the type of profile. This variation means you should always check multiple suppliers. You might find that one supplier offers a better deal on a specific profile type than another.

In conclusion, when planning your project, don’t just look at the price tag. Consider all the factors that influence costs. By doing a little research, you can ensure you’re getting the best value for your money. Remember, every penny counts, especially in large projects!

DKP Steel Profile Weight

The weight of DKP steel profiles plays a pivotal role in various aspects of construction and manufacturing. Why is this important? Well, understanding the weight helps in planning, handling, and transporting these materials efficiently. Imagine trying to lift a heavy beam without knowing its weight. Not only would it be awkward, but it could also lead to safety issues. So, let’s dive into how we can determine the weight of these profiles and why it matters.

First off, the weight of a DKP steel profile is calculated based on its dimensions and the density of the steel. The formula used is:

Weight Volume x Density

Here, the volume is determined by the profile’s dimensions—length, width, and height. The density of steel is typically around 7.85 grams per cubic centimeter. Knowing this, you can easily calculate the weight of any profile you’re working with.

For example, if you have a profile that is 2 meters long, 10 centimeters wide, and 5 centimeters high, you’d first calculate the volume:

Volume Length x Width x Height 200 cm x 10 cm x 5 cm 10,000 cm³

Then, using the density:

Weight 10,000 cm³ x 7.85 g/cm³ 78,500 grams or 78.5 kg

See how straightforward that is? But what does this mean for you in real-world applications? Here are a few key implications:

- Handling: Heavier profiles require more manpower or equipment for transport.

- Transportation: Knowing the weight helps in selecting the right vehicle and planning routes.

- Structural Calculations: Engineers need accurate weight data to ensure safety and stability in construction.

Moreover, the weight of DKP steel profiles can vary significantly based on their size and thickness. For instance, a thicker profile will weigh more than a thinner one of the same dimensions. This variability can affect project budgets and timelines. It’s crucial to consider these factors early in the planning stages to avoid surprises later on.

In conclusion, understanding the weight of DKP steel profiles isn’t just about numbers. It’s about making informed decisions that can impact safety, efficiency, and cost. So next time you’re working with these materials, remember: a little knowledge about weight can go a long way in ensuring your project’s success.

DKP Steel Profile Properties

When it comes to DKP steel profiles, understanding their properties is essential. These profiles are not just any ordinary steel; they are crafted through a process that enhances their performance in various applications. So, what makes DKP steel profiles stand out? Let’s dive into their unique characteristics.

One of the most notable properties of DKP steel is its mechanical strength. This strength is crucial for construction and manufacturing. It means that DKP steel can withstand heavy loads without bending or breaking. Imagine building a bridge or a skyscraper. You wouldn’t want materials that crumble under pressure, right? DKP steel profiles offer that peace of mind.

Another important aspect is corrosion resistance. DKP steel is treated to resist rust and other forms of corrosion. This quality is especially valuable in environments exposed to moisture or chemicals. Think about a factory that deals with wet conditions or a coastal area where saltwater is prevalent. Using DKP steel profiles in these settings ensures longevity and reduces maintenance costs.

Durability is a key property as well. DKP steel profiles are designed to last. They can endure various environmental conditions without losing their integrity. This means fewer replacements and repairs over time. In a world where every penny counts, choosing durable materials can save you a lot in the long run.

Moreover, DKP steel profiles are versatile. They come in various shapes and sizes, making them suitable for different applications. Whether you need beams, columns, or frames, DKP steel can be tailored to fit your project requirements. This adaptability is a game-changer for manufacturers and builders alike.

To illustrate these properties, here’s a quick comparison of DKP steel profiles with other common materials:

| Property | DKP Steel | Other Steel Types | Aluminum |

|---|---|---|---|

| Mechanical Strength | High | Varies | Moderate |

| Corrosion Resistance | Good | Poor | Excellent |

| Durability | Excellent | Varies | Good |

| Versatility | High | Moderate | Low |

In summary, DKP steel profiles possess a unique combination of strength, corrosion resistance, durability, and versatility. These properties make them an excellent choice for various applications in construction and manufacturing. So, the next time you’re considering materials for your project, remember the advantages that DKP steel profiles bring to the table.

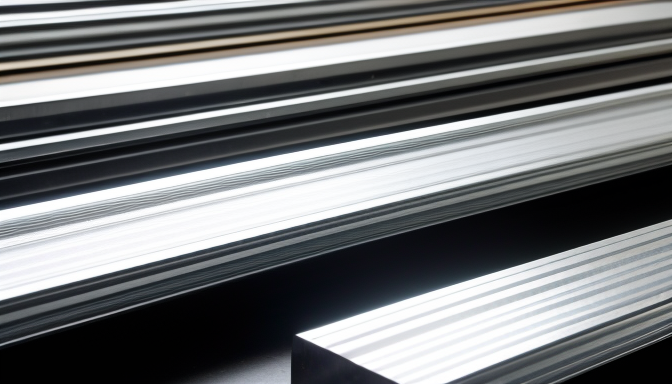

DKP Steel Profile Sizes

When it comes to DKP steel profiles, size really does matter. Choosing the right size for your project can make a world of difference. It’s not just about fitting a piece into a space; it’s about ensuring strength, stability, and efficiency. Think of it like picking the right shoes for a hike. You wouldn’t wear flip-flops on a rocky trail, right? Similarly, the right profile size is crucial for your construction needs.

DKP steel profiles come in a variety of sizes, catering to different applications across industries. Whether you’re working on a small renovation or a large-scale construction project, understanding the available sizes helps you make informed decisions. Standard sizes are readily available, but many manufacturers also offer custom sizing options. This flexibility allows you to tailor the profiles to meet specific requirements.

Here’s a quick overview of the standard sizes you might encounter:

| Profile Type | Width (mm) | Height (mm) | Thickness (mm) |

|---|---|---|---|

| U-Channel | 50 | 100 | 3 |

| I-Beam | 100 | 200 | 5 |

| Box Section | 50 | 50 | 4 |

| Angle Iron | 30 | 30 | 3 |

But how do you choose the right size? Here are some tips:

- Understand Your Project Needs: Consider the load the profile will bear. Heavier loads require stronger profiles.

- Consult with Professionals: Don’t hesitate to ask engineers or architects for advice. They can guide you on the best profile sizes for your specific project.

- Check Local Regulations: Sometimes, local building codes dictate what sizes you can use. Always ensure compliance.

In conclusion, selecting the correct size of DKP steel profiles is essential for the success of your project. It affects not just the aesthetics but also the overall safety and functionality. Remember, just like a well-fitted shoe, the right profile can make all the difference in your construction journey!

Frequently Asked Questions

- What is a cold rolled steel profile?

A cold rolled steel profile is a type of steel that is processed at room temperature to achieve specific shapes and dimensions. This method enhances the material’s strength and surface finish, making it ideal for various applications in construction and manufacturing.

- How is the price of DKP steel profiles determined?

The pricing of DKP steel profiles is influenced by several factors, including market demand, production costs, and regional variations. Understanding these elements can help you budget effectively for your projects.

- What affects the weight of DKP steel profiles?

The weight of DKP steel profiles is determined by their dimensions and thickness. Knowing the weight is crucial for handling and transportation, as well as for ensuring structural integrity in construction projects.

- What are the key properties of DKP steel profiles?

DKP steel profiles are known for their excellent mechanical properties, corrosion resistance, and durability. These characteristics make them suitable for a wide range of applications, from structural support to decorative elements.

- What sizes are available for DKP steel profiles?

DKP steel profiles come in various standard sizes, and many manufacturers offer custom sizing options. Selecting the right size is essential for meeting the specific requirements of your project.

- Can I use DKP steel profiles in outdoor applications?

Yes, DKP steel profiles can be used outdoors, but it’s important to consider their corrosion resistance. Applying protective coatings can enhance their durability in harsh environments.