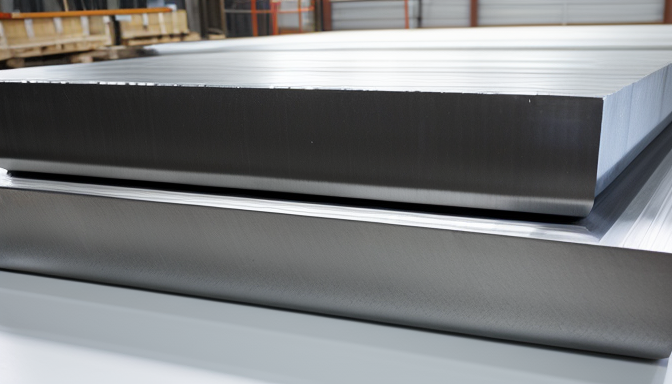

C45 steel sheets are an essential material in various industries due to their unique properties and versatility. But what exactly is C45 steel? It’s a medium carbon steel that boasts a good balance of strength and ductility. This makes it a favorite among manufacturers and builders alike. Think of it as the all-rounder in the world of steel. Whether you’re constructing buildings, making machinery, or crafting automotive parts, C45 steel sheets play a crucial role.

When you hear about C45 steel sheets, you might wonder why they are so popular. The answer lies in their strength and durability. They can withstand significant stress and are resistant to wear and tear. Imagine trying to build a bridge with flimsy materials; it just wouldn’t work. That’s why C45 steel is often the go-to choice for heavy-duty applications.

These steel sheets come in various sizes and thicknesses, making them adaptable to different projects. From small components to large structural elements, there’s a C45 steel sheet that fits the bill. The flexibility in size ensures that whether you’re working on a large construction site or a small workshop project, you’ll find what you need without a hitch.

Furthermore, understanding the price and weight of C45 steel sheets is crucial for anyone looking to purchase them. The price can vary based on market demand, supplier pricing, and even the size of the sheet. As for weight, it’s an important factor in logistics. You wouldn’t want to be caught off guard by heavy materials when planning transportation, right?

In summary, C45 steel sheets are more than just a construction material. They represent reliability and strength, making them a staple in many industries. So, whether you’re a seasoned engineer or a DIY enthusiast, understanding the ins and outs of C45 steel sheets can help you make better choices in your projects.

C45 Steel Sheet Price

Understanding the pricing factors of C45 steel sheets is essential for anyone looking to make a purchase. Prices can vary significantly based on several elements. For instance, the market trends play a crucial role. When demand spikes, prices tend to follow suit. Conversely, during periods of low demand, you might snag a better deal.

Another factor to consider is the supplier pricing. Not all suppliers offer the same rates. Some may provide discounts for bulk purchases, while others might have fixed prices regardless of quantity. It’s always wise to shop around. Compare prices from different vendors to ensure you’re getting the best deal possible.

Additionally, transportation costs can impact the final price. If you’re ordering from a supplier far away, shipping fees can add up quickly. Always factor in these costs when budgeting for your purchase. It’s also helpful to check if the supplier offers free shipping for larger orders.

To give you a clearer picture, here’s a simple table outlining average price ranges based on thickness:

| Thickness (mm) | Average Price (per kg) |

|---|---|

| 2 | $0.80 |

| 5 | $0.75 |

| 10 | $0.70 |

| 15 | $0.65 |

As you can see, the thicker the sheet, the lower the price per kilogram. This trend can be surprising, but it’s often due to the economies of scale in production. Suppliers can produce thicker sheets more efficiently, which can translate into savings for you.

Finally, keep an eye on the global steel market. Prices can fluctuate based on international trade policies, tariffs, and raw material costs. Staying informed about these factors can help you make better purchasing decisions. Remember, knowledge is power in the steel market!

C45 Steel Sheet Weight

The weight of C45 steel sheets plays a significant role in many aspects of construction and manufacturing. It’s not just a number; it’s a critical factor that affects transportation, structural calculations, and even cost management. So, how do we determine the weight of these sheets? Let’s break it down.

First off, the weight of a steel sheet is calculated based on its **dimensions** and **density**. C45 steel has a density of around **7.85 g/cm³**. To find the weight, you can use the formula:

Weight (kg) Length (m) × Width (m) × Thickness (m) × Density (g/cm³) × 1000

Let’s say you have a C45 steel sheet that is **2 meters long**, **1 meter wide**, and **0.01 meters thick**. Plugging these numbers into the formula gives:

Weight 2 × 1 × 0.01 × 7.85 × 1000 157 kg

That’s quite a hefty piece of metal! Understanding this weight is crucial, especially for transportation costs and load-bearing calculations. If you’re planning to use these sheets in a construction project, knowing the weight helps you determine how much support you’ll need. It’s like planning a road trip; you wouldn’t want to overload your vehicle!

Additionally, the weight influences the overall cost of shipping. Heavier materials typically incur higher freight charges. Therefore, when sourcing C45 steel sheets, it’s wise to consider not just the price per sheet but also how much you’ll spend to get them delivered. Every penny counts, right?

In various industries, the weight of C45 steel sheets can impact equipment selection, handling procedures, and even safety measures. For example, in the automotive sector, lighter materials can lead to better fuel efficiency. Conversely, in construction, heavier materials might be necessary for structural integrity. It’s a balancing act that requires careful planning.

In summary, the weight of C45 steel sheets is more than just a figure on a scale. It’s a vital aspect that affects many stages of a project, from planning to execution. Whether you’re a buyer, engineer, or contractor, understanding this can help you make better decisions and avoid unexpected costs. So, the next time you’re dealing with C45 steel sheets, remember: weight matters!

C45 Steel Sheet Properties

C45 steel is a medium carbon steel that boasts a variety of unique properties. These characteristics make it a popular choice in many industries. So, what makes C45 steel sheets stand out? Let’s dive into the details!

First off, one of the most notable features of C45 steel is its strength. With a tensile strength ranging from 570 to 700 MPa, it can handle significant loads without bending or breaking. Imagine trying to lift a heavy object. You need something strong to support it, right? C45 steel provides that support in structural applications.

Another key property is its hardness. C45 steel can be heat-treated to enhance its hardness, making it suitable for tools and machinery parts. This means it can resist wear and tear better than softer steels. Think of it like a tough pair of shoes that can withstand rough terrain. The more durable the material, the longer it lasts!

When it comes to ductility, C45 steel also performs well. It can be drawn into wires or shaped into complex forms without breaking. This flexibility is crucial for manufacturers who need to create intricate designs. Imagine molding clay into different shapes; that’s how easily C45 steel can be manipulated.

Now, let’s not forget about its chemical composition. C45 is primarily composed of iron, with carbon content around 0.45%. This blend gives it a good balance of strength and ductility. Here’s a quick breakdown of its composition:

| Element | Percentage |

|---|---|

| Carbon (C) | 0.42 – 0.50% |

| Manganese (Mn) | 0.60 – 0.90% |

| Silicon (Si) | 0.17 – 0.37% |

| Phosphorus (P) | Max 0.04% |

| Sulfur (S) | Max 0.05% |

In terms of corrosion resistance, C45 steel does require some protection. It’s not stainless steel, after all. However, with proper coatings or treatments, it can resist rust and degradation, which is essential for outdoor applications. Think of it like putting on sunscreen before heading out into the sun; it helps to protect what’s underneath.

Overall, the properties of C45 steel sheets make them a versatile choice for many applications. Whether you’re in construction, manufacturing, or automotive industries, understanding these properties can help you make informed decisions. So, next time you’re working on a project, remember the strength, hardness, and flexibility of C45 steel. It might just be the perfect fit!

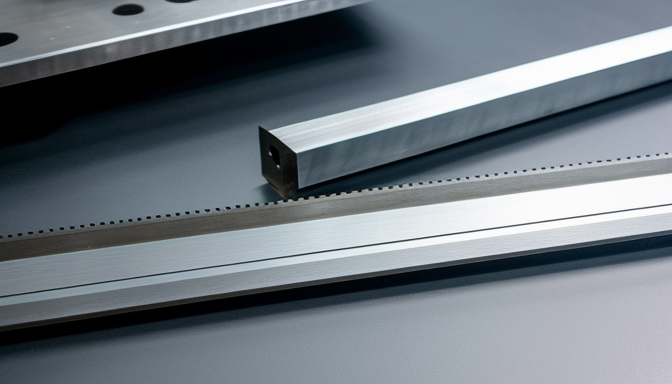

C45 Steel Sheet Sizes

This article explores the essential aspects of C45 steel sheets, including their price, weight, properties, sizes, and applications in various industries.

When it comes to C45 steel sheets, size matters. The dimensions of these sheets can significantly affect their usability in different applications. Whether you’re in construction, manufacturing, or automotive industries, knowing the right size is crucial. Think about it: using the wrong size can lead to inefficiencies and increased costs. So, what sizes are available?

C45 steel sheets typically come in a variety of standard dimensions. The most common sizes include:

- Thickness: Ranges from 1 mm to 100 mm

- Width: Usually available in widths of 1000 mm, 1250 mm, and 1500 mm

- Length: Common lengths are 2000 mm, 2500 mm, and 3000 mm

These sizes cater to a wide range of applications. For instance, if you’re working on a project that requires high strength and durability, opting for a thicker sheet might be beneficial. On the other hand, if you’re looking for something more lightweight for easier handling, thinner options could be the way to go.

It’s also worth noting that custom sizes can often be ordered. Many suppliers offer the flexibility to cut sheets to your specific requirements. This can be particularly helpful if you have a unique project that doesn’t fit standard dimensions. Just imagine how much easier your job will be when you have the exact size you need!

To give you a better idea of how these sizes stack up, here’s a simple table:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 1 | 1000 | 2000 |

| 5 | 1250 | 2500 |

| 10 | 1500 | 3000 |

| 20 | 1000 | 2000 |

| 50 | 1250 | 2500 |

In summary, understanding the sizes of C45 steel sheets is not just about knowing the numbers. It’s about making informed decisions that can impact your project’s success. The right size can enhance performance, reduce waste, and save you money. So, next time you’re in the market for C45 steel sheets, keep these sizes in mind. They could make all the difference!

Frequently Asked Questions

- What is C45 steel?

C45 steel is a medium carbon steel that is widely used in various industries due to its excellent hardness and strength properties. It’s often used for manufacturing components that require high wear resistance and durability.

- What are the typical applications of C45 steel sheets?

C45 steel sheets are commonly used in the automotive industry, construction, and machinery manufacturing. They are ideal for parts like gears, shafts, and other components that undergo significant stress.

- How does the weight of C45 steel sheets affect their use?

The weight of C45 steel sheets is important for transportation and structural calculations. Heavier sheets may require more robust support structures, while lighter sheets can be easier to handle and install.

- What factors influence the price of C45 steel sheets?

The price of C45 steel sheets can vary based on market demand, the thickness of the sheets, and supplier pricing strategies. It’s essential to compare prices from different suppliers to ensure you’re getting a good deal.

- What sizes are available for C45 steel sheets?

C45 steel sheets are available in various sizes and thicknesses to meet different industrial needs. Common dimensions include standard sheet sizes, which can be customized based on specific project requirements.

- What are the mechanical properties of C45 steel?

C45 steel is known for its high tensile strength, good machinability, and ability to withstand high levels of stress. These properties make it suitable for heavy-duty applications.

- Can C45 steel sheets be welded?

Yes, C45 steel sheets can be welded, but it is recommended to use preheating techniques to avoid cracking. Proper welding methods ensure strong joints and maintain the integrity of the material.

- How should C45 steel sheets be stored?

To maintain the quality of C45 steel sheets, they should be stored in a dry and clean environment to prevent rust and corrosion. It’s also advisable to keep them off the ground and covered to protect them from moisture.