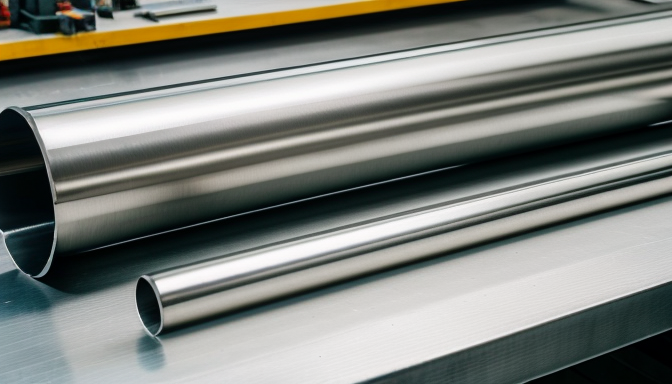

304L seamless stainless steel pipes are a popular choice in various industries due to their remarkable corrosion resistance and durability. These pipes are made from a low-carbon version of 304 stainless steel, which enhances their ability to withstand corrosive environments. Whether you’re in construction, manufacturing, or any other field that requires reliable piping, understanding the specifications and uses of these pipes is essential.

One of the standout features of 304L pipes is their seamless construction. Unlike welded pipes, seamless pipes are formed from a solid piece of metal, which eliminates the risk of weak points that can occur at weld joints. This makes them especially suitable for high-pressure applications. Imagine trying to hold a garden hose together with tape. It might work for a while, but eventually, it will fail. Seamless pipes, on the other hand, are like a sturdy, continuous hose that can handle the pressure without breaking.

These pipes come in various sizes and thicknesses, making them versatile for different applications. From small-scale plumbing to large industrial projects, 304L seamless stainless steel pipes can be tailored to meet specific requirements. Their ability to resist oxidation and maintain structural integrity over time is why many industries rely on them for critical operations.

When you think about it, using the right materials in construction isn’t just about following guidelines—it’s about ensuring safety and efficiency. For instance, in the food and beverage industry, where hygiene is paramount, 304L pipes are favored because they don’t leach harmful substances. This means they not only meet health standards but also contribute to the overall quality of the products being processed.

In summary, 304L seamless stainless steel pipes are not just pipes; they are a crucial component in ensuring the safety and efficiency of various industrial applications. Understanding their specifications and advantages can help you make informed decisions in your projects. So, whether you’re designing a new system or upgrading an existing one, consider the benefits of using 304L seamless stainless steel pipes.

304L Seamless Stainless Steel Pipe Price

When it comes to budgeting for construction or manufacturing projects, understanding the price of 304L seamless stainless steel pipes is essential. Prices can vary significantly based on several factors. Think of it like shopping for a car; the model, features, and even the dealership can impact the final price. Similarly, with 304L pipes, factors such as size, thickness, and market demand play crucial roles in determining cost.

As of now, the price range for 304L seamless stainless steel pipes typically falls between $2.00 to $10.00 per foot. However, this is just a ballpark figure. Prices can fluctuate based on:

- Size: Larger pipes generally cost more due to increased material use.

- Thickness: Thicker walls mean more stainless steel, which can raise the price.

- Market Demand: Prices can rise or fall based on supply and demand dynamics in the industry.

- Supplier: Different suppliers may offer varying prices based on their sourcing and operational costs.

For example, a standard 1-inch diameter pipe may cost around $3.00 per foot, while a larger 6-inch diameter pipe could be priced at about $8.00 per foot. It’s always wise to compare quotes from multiple suppliers to ensure you’re getting a fair deal. Additionally, consider the total quantity needed, as many suppliers offer discounts for bulk purchases.

Another important aspect to consider is the shipping cost. Depending on your location, transporting these pipes can add a significant amount to your overall budget. Always ask suppliers about shipping options and costs upfront. Some may even offer free shipping on larger orders, which can be a nice perk.

In summary, while the price of 304L seamless stainless steel pipes can vary widely, understanding what influences these costs can help you make more informed decisions. By keeping an eye on market trends and shopping around, you can ensure that you’re getting the best value for your project.

304L Seamless Stainless Steel Pipe Weight

When it comes to 304L seamless stainless steel pipes, understanding their weight is essential. Why? Because the weight directly affects both transportation and installation costs. Imagine trying to move a heavy load without knowing its weight. It can lead to unexpected expenses and logistical challenges. Knowing the weight helps in planning effectively, ensuring that you stay within budget.

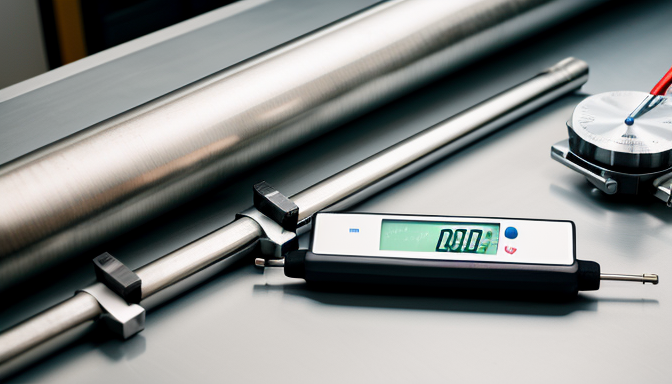

So, how do we calculate the weight of these pipes? The weight is typically determined by the pipe’s dimensions and the density of the material. For 304L stainless steel, the density is about 8.0 g/cm³. Using this density, we can calculate the weight with a simple formula:

Weight (kg) (Outer Diameter - Wall Thickness) x Wall Thickness x Length x Density

Let’s break this down. The outer diameter refers to the total width of the pipe, while the wall thickness is how thick the pipe walls are. The length is straightforward, but it’s crucial to measure accurately. A small error in measurement can lead to significant weight differences.

To give you a better idea, here’s a quick reference table that shows the weight of various sizes of 304L seamless stainless steel pipes:

| Pipe Size (inches) | Weight (kg/m) |

|---|---|

| 1 | 2.68 |

| 2 | 5.00 |

| 3 | 7.50 |

| 4 | 10.00 |

As you can see, the weight increases with the size of the pipe. This is an important factor to consider when planning your project. Larger pipes will not only weigh more but will also require more robust support during installation.

In conclusion, knowing the weight of 304L seamless stainless steel pipes is key to managing costs and ensuring a smooth installation process. Whether you’re working on a small project or a large-scale construction, always factor in the weight. It’s one of those details that can save you from a lot of headaches down the road.

304L Seamless Stainless Steel Pipe Properties

The 304L seamless stainless steel pipe is a standout in the world of piping materials. Why? Because it boasts exceptional properties that make it suitable for a variety of applications. First and foremost, its corrosion resistance is remarkable. This means it can withstand harsh environments without rusting or degrading. Imagine a pipe that can handle both acidic and alkaline substances without breaking a sweat. That’s the magic of 304L.

Another important property is its mechanical strength. This pipe can endure high pressures and extreme temperatures, making it ideal for industries like oil and gas, food processing, and pharmaceuticals. Picture this: you’re in a factory where high-pressure steam is running through the pipes. You want to ensure that those pipes won’t fail. That’s where 304L comes in, providing peace of mind.

Moreover, 304L stainless steel has excellent weldability. This means it can be easily welded without compromising its strength. For those in construction or manufacturing, this is a significant advantage. You won’t have to worry about weak joints or additional treatments after welding. It’s like building a bridge with solid foundations; you want everything to hold up under pressure.

One of the lesser-known but equally important properties is its low carbon content. This characteristic reduces the risk of carbide precipitation during welding. In simpler terms, it helps maintain the integrity of the steel, even after it’s been worked on. This is crucial in applications where the pipes will be exposed to high temperatures.

To give you a clearer picture of what makes 304L stand out, here’s a quick comparison with other common materials:

| Property | 304L Stainless Steel | Carbon Steel | Alloy Steel |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | Good |

| Weldability | High | Moderate | Variable |

| Temperature Resistance | Good | Fair | High |

In summary, the properties of 304L seamless stainless steel pipes make them a reliable choice for many industries. Their ability to resist corrosion, handle high pressures, and maintain structural integrity during welding sets them apart. Whether you’re working on a construction project or a manufacturing line, understanding these properties can help you make informed decisions. After all, when it comes to materials, you want to choose the best for your needs.

304L Seamless Stainless Steel Pipe Sizes

When it comes to 304L seamless stainless steel pipes, size matters. These pipes are not just one-size-fits-all. They come in a variety of dimensions that cater to different industrial needs. From small-scale projects to large industrial applications, understanding the sizes available can make a significant difference in your choice. So, what are the standard sizes?

Generally, 304L pipes are available in both nominal pipe sizes (NPS) and diameter schedules. The nominal sizes range from 1/8 inch to 30 inches in diameter. This means you can find a pipe suitable for almost any project. The diameter schedules, which indicate the wall thickness, can also vary, affecting the pipe’s strength and capacity.

Here’s a quick overview of some common sizes:

| Nominal Pipe Size (NPS) | Outer Diameter (inches) | Wall Thickness (inches) |

|---|---|---|

| 1/2 | 0.840 | 0.065 |

| 1 | 1.315 | 0.109 |

| 2 | 2.375 | 0.154 |

| 3 | 3.500 | 0.216 |

| 4 | 4.500 | 0.237 |

These sizes are just the tip of the iceberg. Depending on your project, you might need something specific. For example, a small plumbing job might only require a 1-inch pipe, while a large construction project could need a 12-inch pipe. It’s all about matching the right size to the job at hand.

Also, keep in mind that the size of the pipe can impact its performance. A larger diameter might be necessary for higher flow rates, while a smaller diameter could be better for tighter spaces. This is where understanding the specifications becomes crucial. You wouldn’t want to choose a pipe that’s too big or too small for your needs, right?

In summary, choosing the correct size of 304L seamless stainless steel pipe is essential for ensuring efficiency and effectiveness in your projects. Whether you’re working on plumbing, structural applications, or manufacturing, the right size can save you time, money, and potential headaches down the line.

Frequently Asked Questions

- What is a 304L seamless stainless steel pipe?

A 304L seamless stainless steel pipe is a type of pipe made from 304L stainless steel, known for its low carbon content. This makes it highly resistant to corrosion and ideal for various industrial applications. Unlike welded pipes, seamless pipes are manufactured without joints, providing greater strength and durability.

- What are the main applications of 304L seamless stainless steel pipes?

These pipes are used in a wide range of industries, including chemical processing, oil and gas, food and beverage, and pharmaceuticals. Their excellent corrosion resistance makes them suitable for transporting liquids and gases in harsh environments.

- How does the weight of 304L seamless stainless steel pipes affect my project?

The weight of these pipes can significantly impact transportation and installation costs. Heavier pipes may require more robust handling equipment and can increase shipping expenses. It’s essential to consider the weight when planning your project budget.

- What factors influence the pricing of 304L seamless stainless steel pipes?

Several factors affect the pricing, including market demand, size, and specifications of the pipes. Additionally, fluctuations in raw material costs and production techniques can lead to price variations. Always compare suppliers to ensure you’re getting the best deal.

- Are there different sizes available for 304L seamless stainless steel pipes?

Yes, 304L seamless stainless steel pipes come in various sizes to accommodate different applications. Standard sizes are available, but custom sizes can also be ordered based on specific project requirements.

- What unique properties does 304L stainless steel offer?

304L stainless steel is known for its excellent corrosion resistance, high strength, and good formability. These properties make it a preferred material in many applications, especially where exposure to corrosive environments is a concern.