16Mo3 steel sheets are a popular choice in industries that require high-strength materials. But what exactly makes them so special? To put it simply, these sheets are made from a specific alloy of steel that includes molybdenum. This addition gives the steel enhanced strength and durability, making it ideal for high-temperature applications. Imagine needing a material that can withstand extreme conditions without faltering—this is where 16Mo3 shines.

When we talk about applications, think of industries like power generation, petrochemicals, and construction. These sectors demand materials that can handle pressure and resist corrosion. 16Mo3 steel sheets fit the bill perfectly. They are often used in the manufacturing of pressure vessels, heat exchangers, and boiler components. It’s like having a trusty tool in your toolbox—always reliable when you need it the most.

Now, let’s dive a bit deeper into the properties of 16Mo3. This steel is known for its excellent weldability and machinability. In simpler terms, it’s easy to work with, which is a huge plus for fabricators. Additionally, it boasts good tensile strength and toughness, making it resilient under stress. You wouldn’t want to use a flimsy material for your projects, right? 16Mo3 ensures that your structures remain intact and safe.

Another important aspect is the availability of sizes. 16Mo3 steel sheets come in various dimensions, catering to different project needs. Whether you need a thin sheet for intricate work or a thicker one for a robust structure, there’s likely an option available for you. Standard sizes can typically range from 1mm to 100mm in thickness, and lengths can vary widely. It’s like picking the right size of shoes—getting the perfect fit makes all the difference.

In conclusion, 16Mo3 steel sheets are much more than just a material; they are a vital part of many industries. Their unique properties and versatility make them a go-to choice for engineers and fabricators alike. When you consider the importance of strength, durability, and adaptability in your projects, it’s clear why 16Mo3 steel sheets hold a significant place in the market.

16Mo3 Steel Sheet Price

When it comes to purchasing 16Mo3 steel sheets, understanding the price is crucial. Prices can fluctuate based on several factors. For instance, the market demand for steel, production costs, and even geographical location can all influence the final price. It’s like shopping for groceries; some days, the prices are higher due to demand, while other days, you might snag a great deal.

Typically, the price of 16Mo3 steel sheets can range from $800 to $1,500 per ton. This wide range is due to variations in thickness, size, and supplier pricing strategies. To make informed decisions, businesses should consider the following:

- Thickness: Thicker sheets usually cost more.

- Quantity: Buying in bulk can sometimes lower the price.

- Supplier: Different suppliers may have different pricing based on their own costs.

Additionally, keep in mind that prices can also be affected by global market trends. For example, if there’s a surge in demand for construction materials, you might see a spike in steel prices. Conversely, during economic downturns, prices might drop as demand decreases.

It’s also wise to consider the total cost of ownership. Sometimes the cheapest option isn’t the best. Quality matters! Investing in high-quality steel can lead to fewer issues down the road, saving you money in repairs or replacements.

For businesses looking to budget effectively, it’s helpful to track prices over time. Keeping an eye on trends can provide insights into when to buy. Some companies even choose to lock in prices through contracts, ensuring they get the best deal possible.

In conclusion, the price of 16Mo3 steel sheets is influenced by various factors. By understanding these elements, businesses can make better purchasing decisions. Remember, it’s not just about finding the lowest price; it’s about finding the best value for your project.

16Mo3 Steel Sheet Weight

The weight of 16Mo3 steel sheets is an important factor to consider for anyone involved in construction or manufacturing. Why? Because knowing how much your materials weigh can impact transportation costs and structural integrity. Imagine trying to lift a heavy steel sheet without knowing its weight. It could lead to unexpected challenges, right?

To calculate the weight of a 16Mo3 steel sheet, you need to know its dimensions and thickness. The formula is quite simple: weight volume × density. The density of 16Mo3 steel is approximately 7.85 g/cm³. So, if you have the dimensions in centimeters, you can easily find out how heavy your steel sheet will be.

For example, let’s say you have a sheet that is 2 meters long, 1 meter wide, and 10 mm thick. First, you convert the dimensions to centimeters:

- Length: 200 cm

- Width: 100 cm

- Thickness: 1 cm

Next, calculate the volume:

Volume Length × Width × ThicknessVolume 200 cm × 100 cm × 1 cm 20,000 cm³

Now, multiply the volume by the density:

Weight Volume × DensityWeight 20,000 cm³ × 7.85 g/cm³ 157,000 g or 157 kg

So, that steel sheet would weigh about 157 kg. Knowing this helps in planning how to transport it safely and how to support it structurally.

When working with multiple sheets, it’s crucial to keep track of their weights. This can be done by creating a simple table to summarize the weights of various sizes and thicknesses:

| Dimensions (cm) | Thickness (mm) | Weight (kg) |

|---|---|---|

| 200 x 100 | 10 | 157 |

| 250 x 125 | 10 | 196 |

| 300 x 150 | 10 | 235 |

Understanding the weight of 16Mo3 steel sheets not only aids in logistics but also ensures that your project remains within budget and meets safety standards. So, the next time you order steel sheets, remember to calculate their weight. It’s a small step that can save you a lot of headaches down the road!

16Mo3 Steel Sheet Properties

The 16Mo3 steel sheet is well-known for its remarkable properties that make it a top choice in various industries. But what exactly makes it stand out? Let’s dive into the key features that define this versatile material.

First off, the mechanical properties of 16Mo3 steel are impressive. It boasts excellent tensile strength, which means it can withstand significant force without breaking. This is crucial for applications where safety and durability are paramount. Imagine using a material that can handle the pressures of high-temperature environments. That’s what 16Mo3 does! It can endure temperatures up to 500 degrees Celsius, making it ideal for boiler and pressure vessel construction.

Now, let’s talk about its chemical composition. 16Mo3 is an alloy steel, primarily made of iron, with a mix of elements like molybdenum and chromium. These elements enhance its strength and resistance to corrosion. In fact, the presence of molybdenum is what gives it that extra edge. It improves the steel’s toughness and hardenability. So, if you’re working on a project that involves harsh conditions, this steel sheet is a reliable choice.

Another important aspect is its ductility. This property allows 16Mo3 to be easily formed and shaped without breaking. It’s like molding clay; you can reshape it into various forms without losing its integrity. This makes it perfect for manufacturing components that require intricate designs.

Additionally, 16Mo3 steel sheets have a good balance of weldability and machinability. You can easily weld it to other materials, which is a huge plus in construction and fabrication. Just think about how many projects involve joining different materials together. With 16Mo3, you don’t have to worry about compromising strength at the joints.

To summarize, here are the standout properties of 16Mo3 steel sheets:

- Tensile Strength: High resistance to breaking under tension.

- Temperature Resistance: Effective in high-temperature environments.

- Chemical Composition: Contains molybdenum for enhanced toughness.

- Ductility: Easily shaped without breaking.

- Weldability: Can be welded to other materials without losing strength.

These properties make 16Mo3 steel sheets a popular choice in industries such as construction, energy, and manufacturing. Whether you’re building a bridge or constructing a pressure vessel, knowing the properties of this steel can help you make informed decisions that lead to safer and more durable structures.

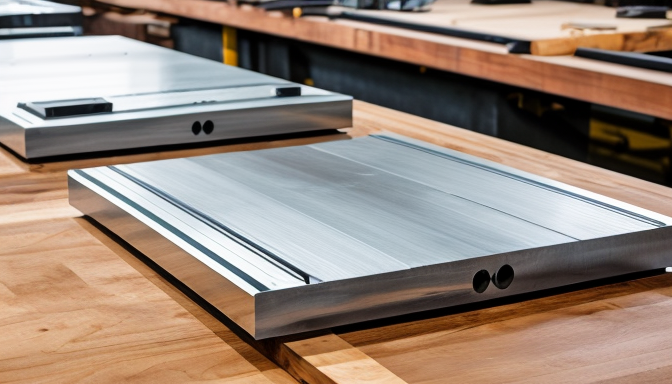

16Mo3 Steel Sheet Sizes

When it comes to 16Mo3 steel sheets, size really does matter. These sheets are not just a one-size-fits-all solution. They come in a variety of sizes and thicknesses, designed to meet the specific needs of different projects. Imagine trying to fit a square peg in a round hole—it’s just not going to work! That’s why understanding the available sizes is crucial for anyone working with this type of steel.

Typically, 16Mo3 steel sheets are available in standard dimensions, but many suppliers also offer custom sizes to accommodate unique project requirements. The most common thicknesses range from 6 mm to 100 mm. However, you can often find options outside this range if you know where to look. For instance, if you need a thinner sheet for a lightweight application, or a thicker one for heavy-duty use, there are options available.

To give you a clearer picture, here’s a simple table showing some standard sizes:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 6 | 1000 | 2000 |

| 8 | 1200 | 2400 |

| 10 | 1500 | 3000 |

| 12 | 2000 | 6000 |

These dimensions are just a starting point. Depending on your needs, you might want to explore further. Many suppliers are willing to cut sheets to your specified size. This flexibility can save you time and reduce waste, which is always a plus!

But why does size matter so much? Well, the right dimensions can significantly impact the performance and durability of the final product. For example, using a thicker sheet in high-stress applications can provide added strength, while a thinner sheet might be perfect for lighter structures. It’s all about matching the steel sheet size to the specific demands of your project.

In conclusion, when selecting 16Mo3 steel sheets, consider not just the standard sizes but also the possibility of custom dimensions. This way, you can ensure that you get the right fit for your project, maximizing both efficiency and effectiveness. Remember, the right size can make all the difference!

Frequently Asked Questions

- What is 16Mo3 steel sheet used for?

16Mo3 steel sheets are primarily used in the manufacture of pressure vessels and boilers. Their unique properties make them ideal for high-temperature applications, especially in industries such as oil and gas, power generation, and chemical processing.

- How is the price of 16Mo3 steel sheets determined?

The price of 16Mo3 steel sheets can vary based on several factors, including market demand, thickness, size, and the supplier’s pricing strategy. It’s essential to compare quotes from different suppliers to get the best deal for your project.

- What are the mechanical properties of 16Mo3 steel?

16Mo3 steel exhibits excellent mechanical properties such as high tensile strength, good weldability, and resistance to creep. These characteristics ensure that it performs well under high temperatures and pressures, making it a reliable choice for critical applications.

- How do I calculate the weight of a 16Mo3 steel sheet?

To calculate the weight of a 16Mo3 steel sheet, you can use the formula: Weight (kg) Length (m) × Width (m) × Thickness (m) × Density (7850 kg/m³). This will give you an accurate estimate of the sheet’s weight for transportation and structural calculations.

- What sizes are available for 16Mo3 steel sheets?

16Mo3 steel sheets are available in various standard sizes, typically ranging from 1mm to 100mm in thickness and up to 3m in width and 12m in length. Custom sizes can also be ordered based on specific project requirements.

- Are there any special considerations when handling 16Mo3 steel sheets?

Yes, when handling 16Mo3 steel sheets, it’s crucial to wear appropriate safety gear due to their weight and sharp edges. Additionally, ensure that they are stored correctly to prevent any damage or corrosion.