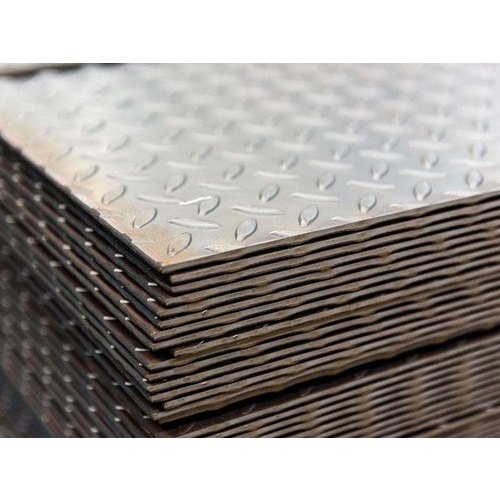

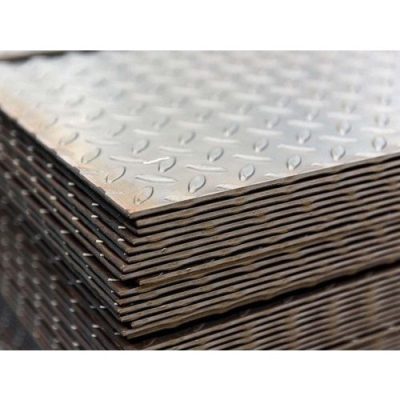

Checkered Sheet Metal Prices

Checkered sheet metal is a type of metal sheet that has a pattern of raised squares or diamonds embossed on its surface. This pattern, often referred to as “checker plate” or “diamond plate,” provides several benefits:

- Increased traction: The raised pattern provides better grip, making it ideal for applications where slip resistance is crucial, such as flooring, walkways, and ramps.

- Enhanced durability: The raised pattern can help distribute weight and prevent dents or scratches.

- Improved aesthetics: Checkered sheet metal can add a rugged and industrial look to various projects.

Common applications of checkered sheet metal include:

- Industrial flooring: In factories, warehouses, and workshops, checkered sheet metal flooring provides a durable, slip-resistant surface.

- Automotive components: It is used for truck bed liners, floor mats, and other vehicle parts.

- Machinery components: Checkered sheet metal can be used for machine bases, platforms, and control panels.

- Architectural elements: It can be incorporated into building facades, stair treads, and handrails.

- DIY projects: Homeowners often use checkered sheet metal for garage floors, toolboxes, and other projects.

When choosing checkered sheet metal, consider the following factors:

- Material: The most common materials are steel and aluminum. Steel is generally stronger and more durable, while aluminum is lighter and more corrosion-resistant.

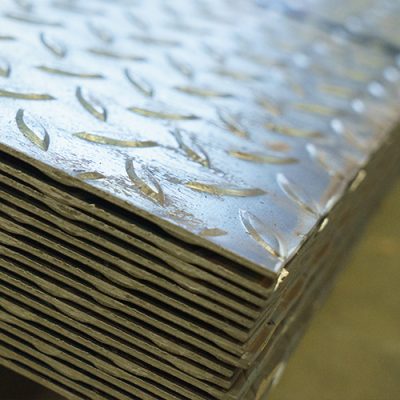

- Thickness: The thickness of the sheet depends on the intended use. Thicker sheets are more suitable for heavy-duty applications, while thinner sheets may be adequate for lighter-duty purposes.

- Finish: Checkered sheet metal can be finished in various ways, including galvanized, painted, or powder-coated. The finish affects the appearance, durability, and corrosion resistance.

Checkered Sheet Metal Price Table

| Material | Thickness (mm) | Size (ft) | Finish | Approximate Price/Sq. Ft. |

|---|---|---|---|---|

| Steel | 3 | 4×8 | Galvanized | $10 – $15 |

| Aluminum | 2 | 4×8 | Mill finish | $15 – $20 |

| Stainless Steel | 1.5 | 4×8 | Brushed | $25 – $35 |

Checkered Sheet Metal Grades

Checkered sheet metal is typically made from various grades of steel, aluminum, or stainless steel. The grade of the material determines its properties, such as strength, durability, and corrosion resistance. Here are some common grades used for checkered sheet metal:

Steel Grades

- ASTM A36: A general-purpose structural steel known for its good balance of strength and weldability.

- ASTM A500: A high-strength low-alloy steel offering excellent strength-to-weight ratio.

- ASTM A1008: A low-carbon steel commonly used for cold-formed shapes and sheet metal products.

Aluminum Grades

- 6061: A versatile aluminum alloy known for its good strength, corrosion resistance, and weldability.

- 5052: Another popular alloy offering excellent corrosion resistance and formability.

- 3003: A softer aluminum alloy with good formability and moderate strength.

Stainless Steel Grades

- 304: A common austenitic stainless steel with good corrosion resistance and formability.

- 316: A higher chromium and molybdenum content stainless steel providing superior corrosion resistance, especially in marine environments.

- 410: A martensitic stainless steel offering high strength and hardness but may require heat treatment for optimal properties.

The specific grade of checkered sheet metal used depends on the intended application and the required properties. For example, a high-strength steel grade might be chosen for heavy-duty industrial flooring, while a corrosion-resistant stainless steel grade might be preferred for outdoor applications or marine environments.