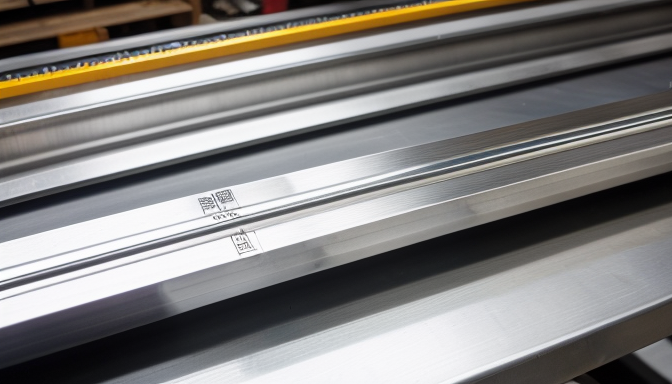

When it comes to 316L seamless stainless steel pipes, understanding their significance is key. These pipes are not just any ordinary pipes; they are engineered for excellence. Imagine a pipe that can withstand harsh environments, resist corrosion, and maintain its strength over time. That’s what 316L offers. It’s like having a reliable friend who never lets you down, no matter the situation.

These pipes are widely used across various industries. From chemical processing to oil and gas, their applications are numerous. Why? Because they are built to last. The seamless design means there are no welds, which enhances their strength and durability. Think of it as a well-crafted piece of art—smooth, flawless, and robust.

But what makes 316L special? The secret lies in its composition. This stainless steel contains molybdenum, which boosts its resistance to corrosion, especially in chloride environments. Picture yourself by the ocean; the salty air can be harsh, but 316L stands strong. This property makes it a favorite in marine applications, where exposure to saltwater is a constant challenge.

Now, let’s talk about the price. Understanding the cost of these pipes is crucial for budgeting. Prices can fluctuate based on several factors, such as market demand and the cost of raw materials. For instance, when demand spikes, so do prices. It’s like going to a concert; if everyone wants to go, ticket prices will soar!

Weight is another important aspect. The weight of a 316L seamless stainless steel pipe varies depending on its dimensions and thickness. Knowing how to calculate the weight is essential, especially for transportation and installation. After all, you wouldn’t want to be caught off guard when the delivery truck arrives, would you?

In terms of sizes, 316L pipes come in a variety of dimensions to meet different industrial needs. Whether you need a small pipe for a specific application or a larger one for heavy-duty tasks, there’s a size that fits. Choosing the right size can make all the difference, just like picking the right tool for a job.

In summary, 316L seamless stainless steel pipes are a cornerstone in various industries. Their unique properties, combined with their versatility, make them an excellent choice for anyone looking for reliable piping solutions. So, the next time you think about pipes, remember the strength and durability of 316L. It’s not just a pipe; it’s a promise of quality.

316L Seamless Stainless Steel Pipe Price

Understanding the pricing factors of 316L seamless stainless steel pipes is crucial for budgeting in projects. Prices can fluctuate based on various elements. For instance, the demand for these pipes can change due to market trends. When industries ramp up production, the demand for materials like 316L stainless steel often rises. This can lead to higher prices. Conversely, during slower economic times, prices may drop.

Another factor affecting price is the source of materials. If the raw materials are sourced from regions with higher labor costs, this can directly impact the final price. Additionally, the manufacturing process plays a role. Seamless pipes require advanced technology, which can add to production costs.

Here’s a breakdown of some key factors that influence the pricing:

- Market Demand: High demand can lead to higher prices.

- Material Sourcing: Costs vary based on where the materials come from.

- Manufacturing Process: Seamless pipes require specialized techniques.

- Thickness and Diameter: Larger or thicker pipes generally cost more.

To give you a clearer picture, let’s take a look at a sample price range for 316L seamless stainless steel pipes. Prices can vary widely, but here’s a rough estimate based on size:

| Pipe Diameter (inches) | Price per Foot ($) |

|---|---|

| 1 | 10 – 15 |

| 2 | 20 – 30 |

| 3 | 30 – 50 |

| 4 | 50 – 70 |

As you can see, the price can vary significantly based on the diameter of the pipe. This is important to consider when planning your project. Always remember to compare prices from different suppliers. It’s a good idea to get quotes from multiple sources. This way, you can ensure that you’re not overpaying.

In conclusion, when budgeting for 316L seamless stainless steel pipes, keep these factors in mind. Understanding how prices work can save you money and help you make informed decisions. It’s all about being smart with your resources!

316L Seamless Stainless Steel Pipe Weight

When it comes to 316L seamless stainless steel pipes, understanding their weight is essential. Why? Because weight plays a crucial role in transportation and installation. Imagine trying to move a heavy load without knowing how much it weighs. It can be quite a challenge, right?

The weight of these pipes varies based on their dimensions and thickness. Typically, the formula to calculate the weight of a seamless pipe is:

Weight (lbs) (OD - Wall Thickness) x Wall Thickness x Length x 0.098

Where OD is the outer diameter, and the Wall Thickness is the thickness of the pipe wall. This formula gives you a good estimate of how much your pipe will weigh. Knowing this helps in planning logistics effectively.

For example, here’s a quick reference table showing the approximate weights of common sizes:

| Pipe Size (inches) | Wall Thickness (inches) | Weight (lbs/ft) |

|---|---|---|

| 1 | 0.065 | 0.133 |

| 2 | 0.065 | 0.276 |

| 3 | 0.065 | 0.467 |

| 4 | 0.065 | 0.668 |

As you can see, the weight increases with the size and thickness of the pipe. This is important to consider when planning a project. You wouldn’t want to order pipes that are too heavy for your team to handle!

Additionally, the weight affects shipping costs. Heavier pipes mean higher transportation fees. So, if you’re on a budget, it’s wise to factor in the weight alongside other costs. Many projects have gone over budget simply because the weight of materials was underestimated.

In summary, understanding the weight of 316L seamless stainless steel pipes is more than just a number. It impacts everything from logistics to budgeting. Always keep weight in mind when planning your next project. It can save you time, money, and a lot of headaches.

316L Seamless Stainless Steel Pipe Properties

When it comes to 316L seamless stainless steel pipes, their properties are nothing short of impressive. These pipes are highly sought after in various industries due to their unique characteristics. But what exactly makes them stand out? Let’s dive into the details.

First off, one of the most remarkable properties of 316L stainless steel is its corrosion resistance. This alloy contains molybdenum, which enhances its ability to withstand harsh environments, especially those that involve chlorides. Think of it as a shield against rust and pitting. If you’ve ever dealt with rust on metal, you know how frustrating it can be. With 316L, you can say goodbye to those worries!

Another essential property is its durability. 316L pipes are engineered to last. They can handle high temperatures without losing their structural integrity. This makes them ideal for applications in industries like oil and gas, where conditions can be extreme. Imagine trying to transport hot liquids through a weak pipe—it wouldn’t end well, right? That’s why durability is key.

Next up is tensile strength. This property refers to how much force a material can withstand while being stretched. 316L stainless steel has a high tensile strength, making it less likely to break under pressure. This is crucial in applications that require pipes to bear heavy loads. Picture a bridge: it needs to be strong enough to support traffic. Similarly, pipes need to be robust to ensure safety and reliability.

Temperature tolerance is another factor to consider. 316L pipes can operate effectively in both high and low-temperature environments. This versatility is a game changer for industries that experience fluctuating temperatures. For instance, in the food processing industry, pipes must handle both freezing and boiling conditions without compromising quality.

Furthermore, 316L stainless steel is known for its ease of fabrication. Whether it’s welding, machining, or forming, this material can be easily manipulated. This means that manufacturers can create various shapes and sizes to fit specific needs. It’s like having a flexible tool that adapts to your project’s requirements.

In summary, the properties of 316L seamless stainless steel pipes make them a top choice for many applications. Their corrosion resistance, durability, tensile strength, temperature tolerance, and ease of fabrication all contribute to their popularity. Understanding these properties can help you make informed decisions when selecting the right pipe for your project.

316L Seamless Stainless Steel Pipe Sizes

When it comes to 316L seamless stainless steel pipes, size truly matters. Choosing the right size isn’t just about aesthetics; it’s about functionality. Imagine trying to fit a square peg in a round hole. It just won’t work! The dimensions you select can impact everything from installation to overall performance in various applications.

Standard sizes for these pipes often fall under specific industry guidelines. Typically, you’ll find diameters ranging from 1/8 inch to 36 inches. But remember, it’s not just about the diameter. The wall thickness also plays a crucial role. For instance, pipes can be categorized into different schedules, such as Schedule 10, Schedule 40, and Schedule 80. Each schedule denotes varying wall thicknesses, which directly affect the pipe’s strength and pressure tolerance.

Here’s a quick breakdown of common sizes and their applications:

| Diameter (inches) | Schedule | Common Use |

|---|---|---|

| 1/2 | Schedule 40 | Residential plumbing |

| 2 | Schedule 80 | Industrial piping systems |

| 6 | Schedule 10 | Food processing |

| 12 | Schedule 40 | Oil and gas transportation |

Choosing the right size can feel overwhelming, but it doesn’t have to be. Think about the application first. Will it carry water, gas, or chemicals? Each substance has its own requirements. For instance, if you’re working with corrosive materials, a thicker wall might be necessary. This ensures the pipe can handle the pressure without compromising safety.

Moreover, consider the installation environment. Are you working indoors or outdoors? Will the pipe face extreme temperatures? These factors can influence your size choice as well. For example, a larger diameter may be needed for outdoor applications to allow for thermal expansion.

In conclusion, when selecting the size of your 316L seamless stainless steel pipe, always keep the end use in mind. It’s not just about picking a number; it’s about ensuring that your choice meets the demands of your specific project. By understanding the different sizes and their applications, you’ll be better equipped to make an informed decision.

Frequently Asked Questions

- What is 316L seamless stainless steel pipe?

316L seamless stainless steel pipe is a type of pipe made from a low-carbon version of 316 stainless steel. It’s known for its excellent corrosion resistance and is often used in environments that involve harsh chemicals or high temperatures.

- What factors influence the price of 316L seamless stainless steel pipes?

The price of 316L seamless stainless steel pipes can be affected by several factors, including raw material costs, market demand, manufacturing processes, and the size and thickness of the pipe. Understanding these can help you budget effectively for your projects.

- How can I determine the weight of a 316L seamless stainless steel pipe?

To determine the weight of a 316L seamless stainless steel pipe, you can use the formula: Weight (Outer Diameter – Wall Thickness) x Wall Thickness x Length x Density. Remember that the density of 316L stainless steel is approximately 8.0 g/cm³.

- What are the key properties of 316L stainless steel?

316L stainless steel is renowned for its exceptional corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It’s also non-magnetic and offers good weldability, making it suitable for various industrial applications.

- What sizes are available for 316L seamless stainless steel pipes?

316L seamless stainless steel pipes come in a variety of sizes, typically ranging from 1/8 inch to 30 inches in diameter. The size you choose should depend on the specific requirements of your project, such as flow rate and pressure.

- In what industries are 316L seamless stainless steel pipes commonly used?

These pipes are widely used in industries like chemical processing, oil and gas, pharmaceuticals, and food processing due to their durability and resistance to corrosion. They are essential for applications where hygiene and safety are paramount.